Friction energy dissipation beam falling prevention device

A technology of frictional energy consumption and anti-falling beams, applied in bridges, bridge parts, bridge construction, etc., to achieve the effect of easy maintenance, easy production, and clear concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

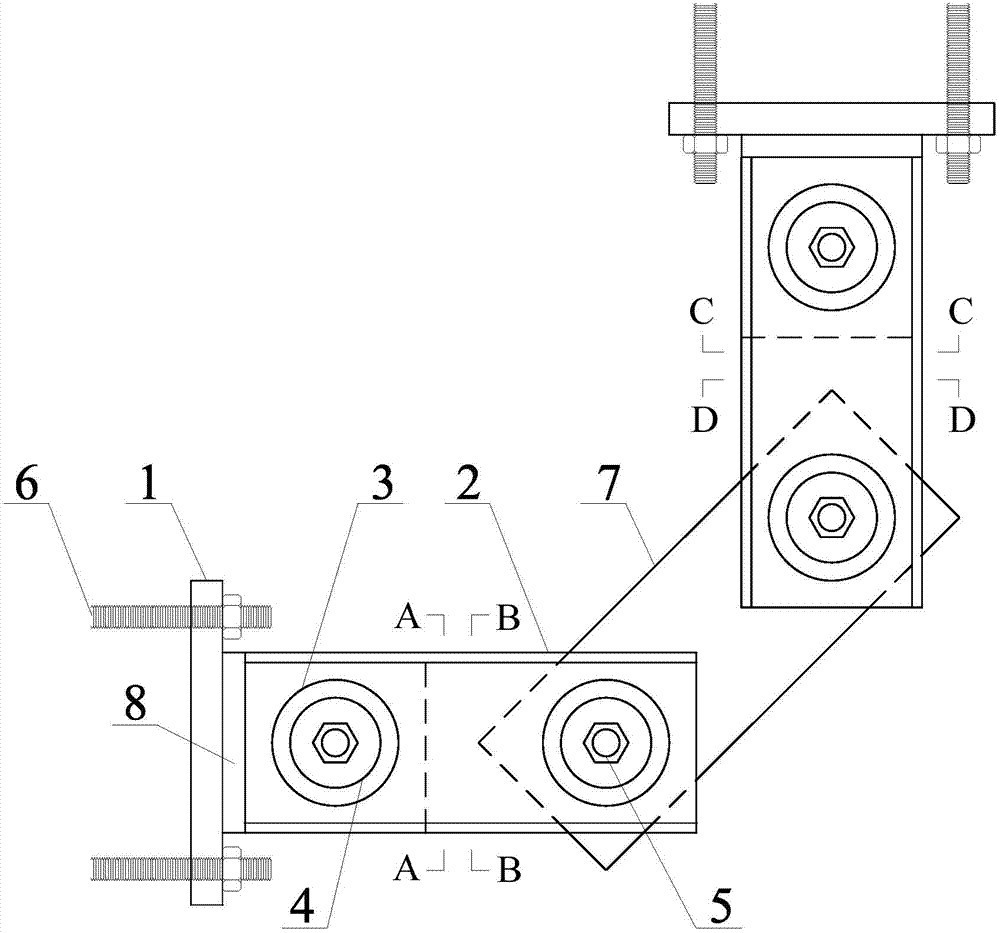

[0022] A frictional energy dissipation anti-falling beam device is composed of two fixed end components respectively connected with bridge pier and beam body, two channel steel systems, a connecting steel plate and four rotational frictional energy dissipation hinges.

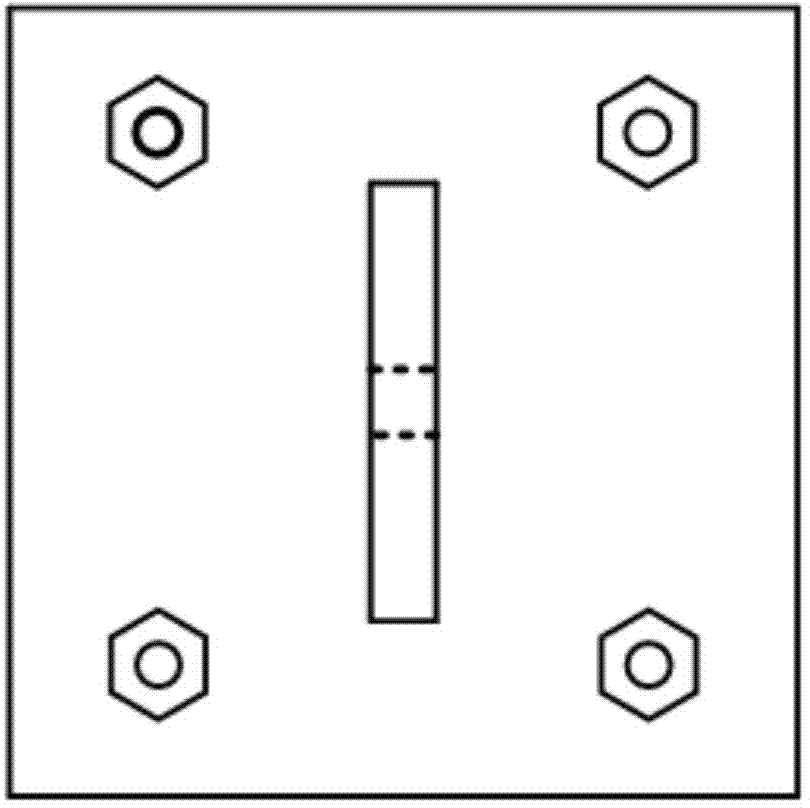

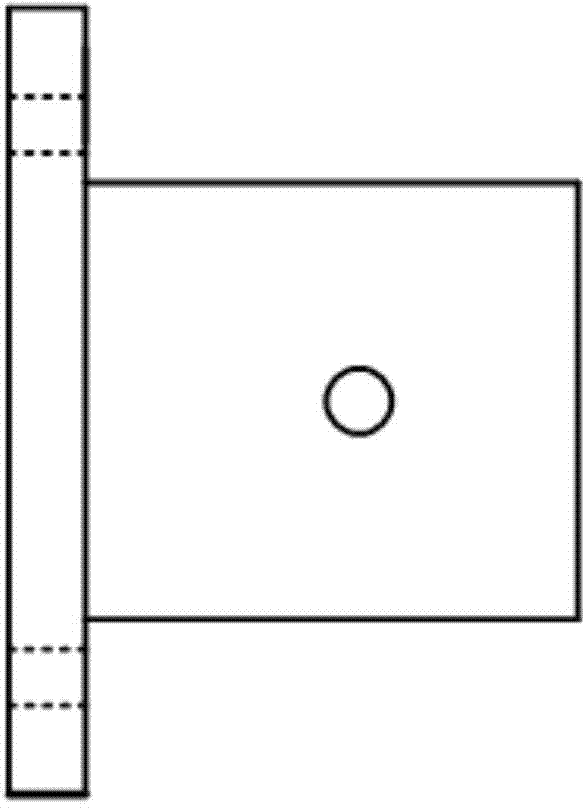

[0023] In this example, the fixed end assembly is welded by two steel plates, one of which is a fixed plate 1 anchored by embedded high-strength bolts 6, and the other is an overhanging steel plate welded at the center of the fixed plate and protruding outward 8. There are two fixed end assemblies in total, wherein the fixed end assembly in the horizontal direction is anchored on the bridge pier through embedded bolts, and the fixed end assembly in the vertical direction is anchored on the beam body through embedded bolts. The channel steel system consists of two back-to-back channel steels 2, the channel steel model is No. 20, and the length is about 50 cm. The central overhanging steel plate 8 of the fixed e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com