Measuring method of gas pressure observation system for downhole drilling in water-bearing coal rock

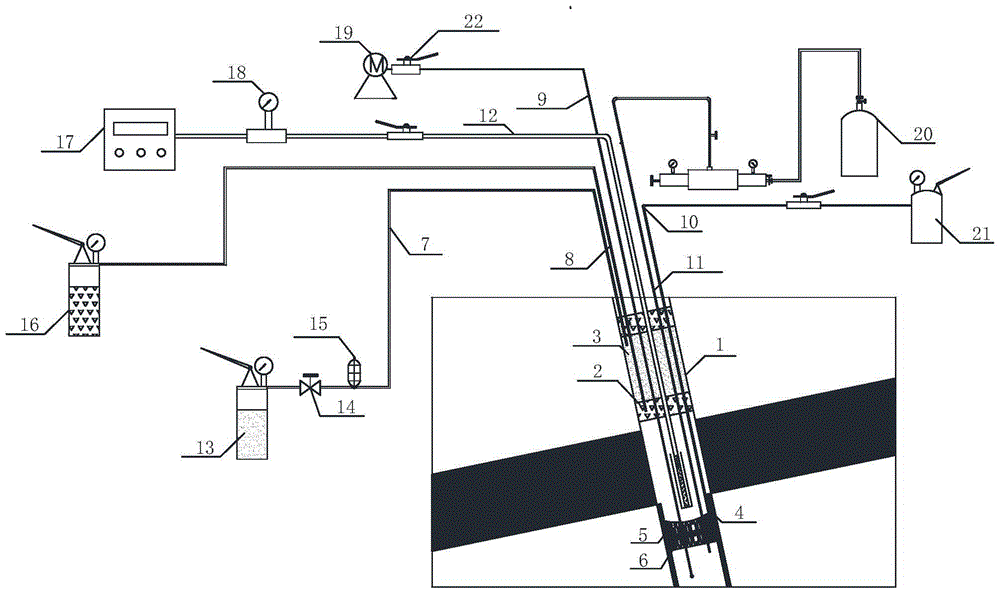

A gas pressure and observation system technology, which is applied in surveying, earthwork drilling, wellbore/well components, etc., can solve problems such as water accumulation in downhole drilling, and achieve continuous and accurate measurement and reduce impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In the present invention, the method for measuring gas pressure observation system for downhole drilling in water-bearing coal rock specifically includes the following steps:

[0041] (1) Drilling holes: Use conventional coal mine drilling equipment to drill down drill holes 1 in the coal rock roadway to the coal seam, the hole is deep to a certain distance through the coal seam;

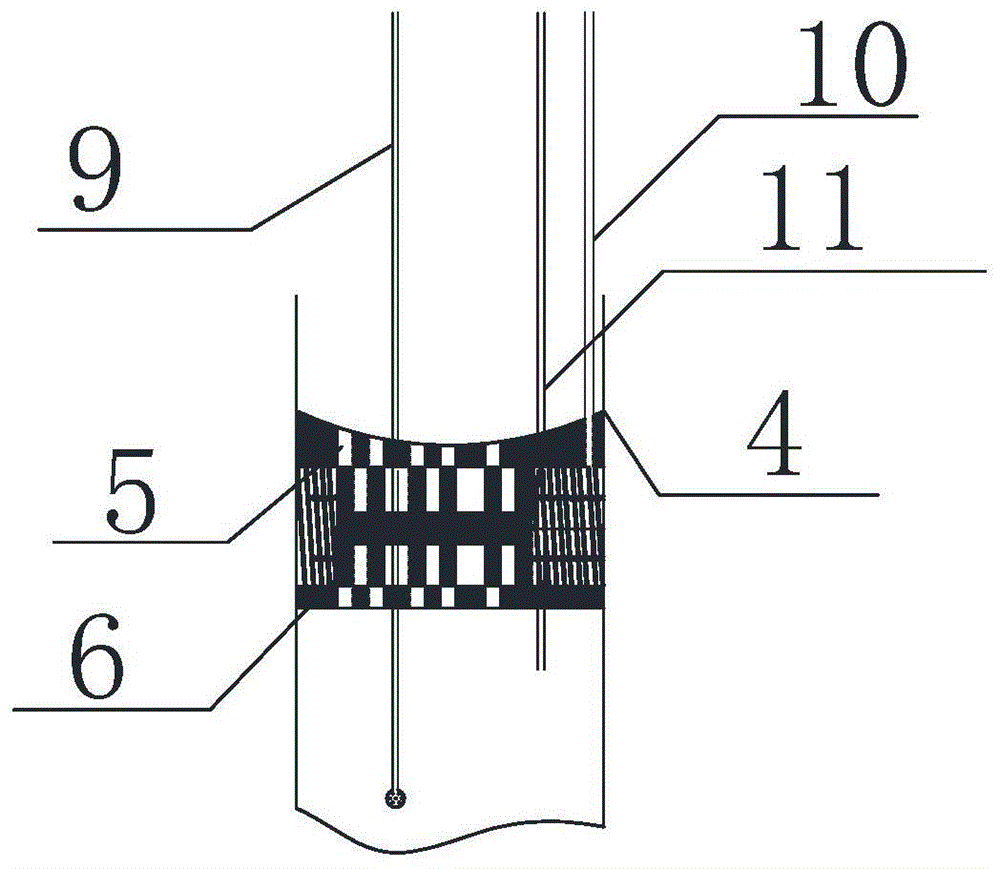

[0042] (2) Water-permeable device: clean the debris in the borehole, install the water-permeable device 4 in the borehole, fill the pores between the water-permeable device 4 and the borehole 1 with the filling material, and do a pressure test after curing for a certain period of time , If the experiment is unsuccessful, reinstall the permeable device 4;

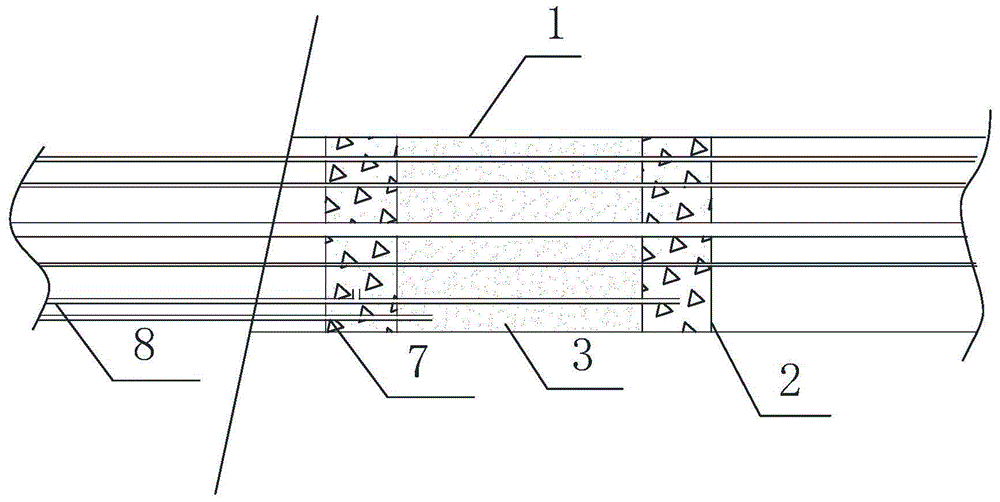

[0043] (3) Sealing the borehole: After the pressure test is successful, install the relevant pipes on the baffle, use the baffle to form 2 No. 1 sealed chambers 2 and 1 No. 2 sealed chamber 3, first use the curing material pressure tank 16 to cure...

Embodiment 2

[0048] The difference from Example 1 is that the drilling drainage method in step (5) is different. Another drainage method is to drain under the pressure difference condition, that is, first use the air supply pipe 11 to perform a little pressure relief to form the upper and lower cavities. The pressure difference is then used to permeate the water. After the water permeation is completed, the pressure of the oil pipeline 10 is relieved, the piston 6 moves under the pressure of the spring, and the permeable hole is closed by the piston, so that the permeable device 4 is in a sealed state; if the amount of water is small, then The water is sealed under the permeable device 4, and if the amount of water is large, the high-pressure gas tank 20 is used to press in the high-pressure gas through the air supply pipe 11, and the water can be discharged through the drainage pipe 9 or pumped out through the drainage motor 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com