Unit pipeline mounting stabilizing device

A pipeline installation and stabilizing device technology, applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of potential safety hazards, no fixing devices, and low efficiency in the installation process, and achieve simple structure and firm fixation , The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

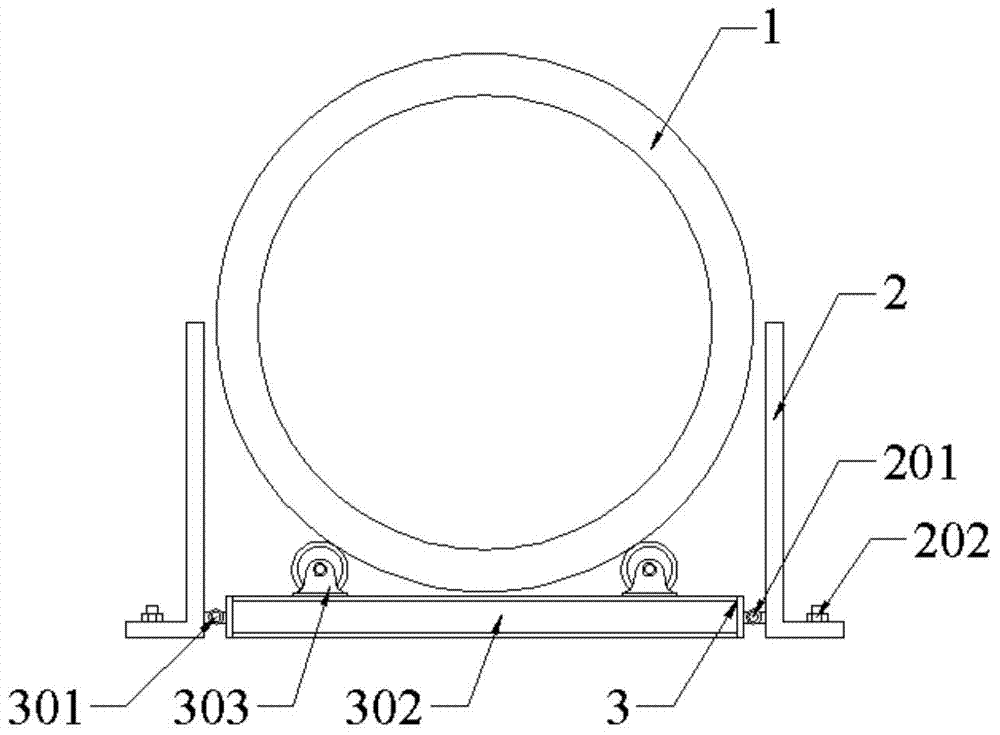

[0018] like Figure 1-Figure 3 As shown, a unit pipeline installation and stabilization device includes a support base 3 and a positioning rod 2 .

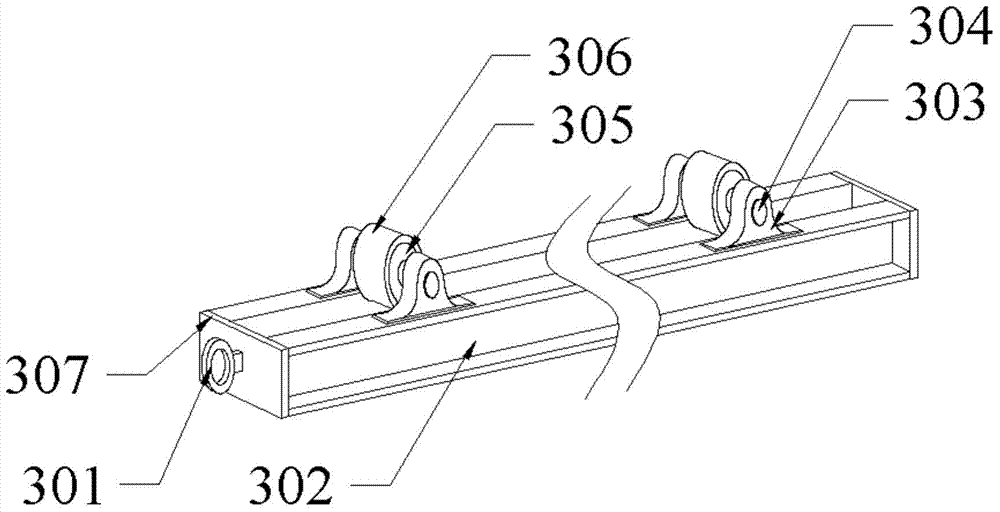

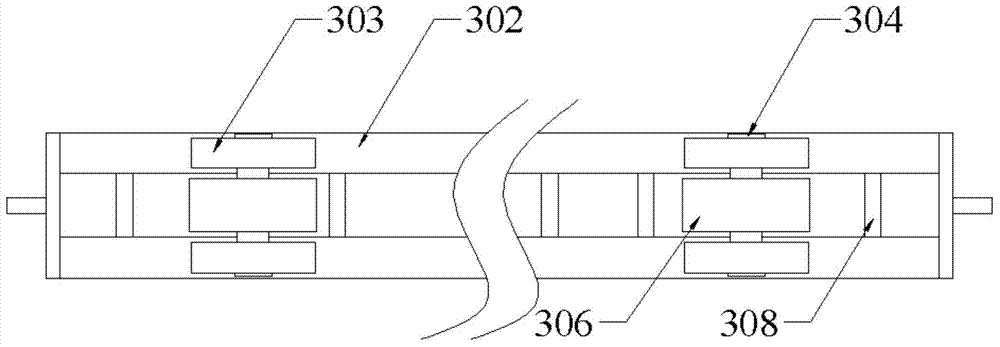

[0019] The supporting seat 3 includes a base 302 , a roller seat 303 symmetrically arranged on the base 302 and a roller 304 fixed on the roller seat 303 . The roller 305 is sleeved on the roller shaft 304 and can rotate around it in a vertical plane. The axial direction of the roller 305 is parallel to the axial direction of the unit pipe 1 . There are two rollers 305, which are symmetrically arranged on the base 302, and support the unit pipe 1. The outer surface of the roller 305 is provided with a protective layer 306 made of high elastic rubber, plastic or other materials. The protective layer 306 has a rough surface, and the protective laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com