Novel heat preserving layer structure

An insulating layer and a new type of technology, which are applied in the fields of heat preservation, pipeline protection, and pipeline protection through thermal insulation, can solve the problems that equipment cannot be put into production quickly, cannot play a role in heat preservation, and heat convection is unavoidable, so as to achieve economical and Outstanding social benefits, solving thermal expansion problems, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

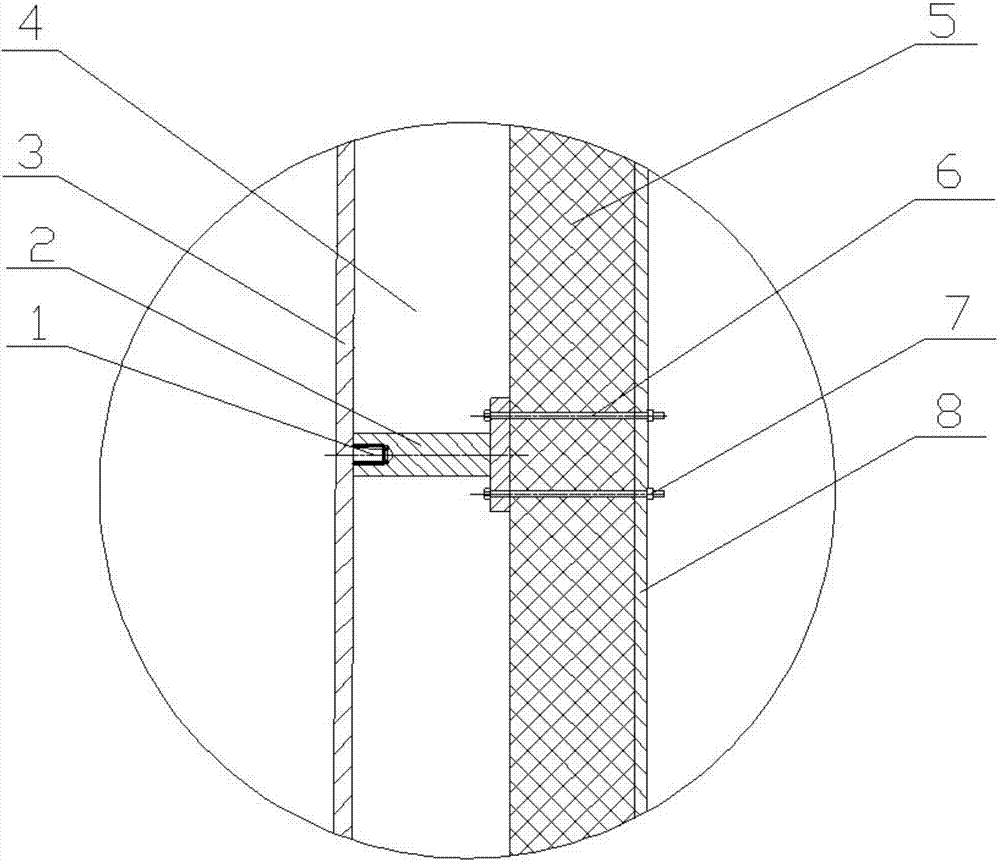

[0013] The present invention will be further described below in conjunction with the accompanying drawings. like figure 1 As shown, a new type of insulation layer structure mainly includes screws 1, T-shaped vacuum main ribs 2, insulation container walls 3, vacuum insulation layer 4, insulation layer 5, bolts 6, and protective reflection layer 8. The screw 1 is welded together with the insulation container wall 3, and is used to connect the T-shaped vacuum main rib 2 and the insulation container wall 3, wherein the vacuum is drawn between the insulation container wall 3 and the insulation layer 5, and the T-shaped vacuum main rib 2 and the insulation layer 5 They are connected together with bolts 6, and the bolts 6 penetrate the protective reflection layer 8 and are fixed with nuts 7.

[0014] Finally, it should be noted that: the above embodiments are only used to illustrate the present description and not to limit the technical solution described in the present invention; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com