Overhead ground wire lifter

An overhead ground wire and lifter technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of the hoop poles sliding down, inconvenient erection, difficult operation, etc., achieving easy operation, simple structure, and reducing the number of people working at heights. effect of numbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

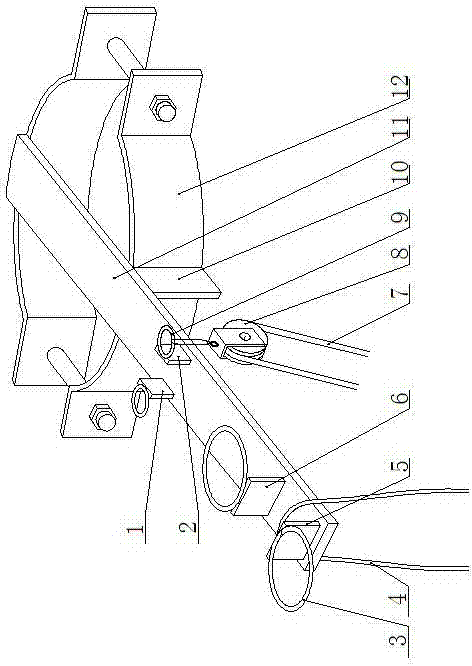

[0011] Example: such as figure 1 As shown, the overhead ground wire lifter is composed of a hoop 12, a crossbeam 11 installed on the hoop 12, a suspension point arranged on the crossbeam 11, and a fixed pulley 8 articulated on the suspension point. The rear end of the crossbeam 11 is flexibly connected with the hoop 12, the middle part is placed on the hoop 12, the front part stretches out from the hoop 12, and a suspension point is arranged on the extension of the crossbeam 11. One of the suspension points links to each other with fixed pulley 8, and safety rope 7 is wound on fixed pulley 8. A support plate 10 is provided at the lower end of the crossbeam 11 overlapping with the hoop 12 , and the support plate 10 is clipped to the outer circumference of the hoop 12 when the hoop 12 is closed.

[0012] The suspension points are respectively arranged at the front end of the crossbeam 11, the left and right sides of the front end and the middle part. The corresponding four sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com