Nonwoven materials containing chlorhexidine acetate and triclosan

A non-woven material, chlorhexidine acetate technology, applied in the field of medical products, can solve the problems of increasing liquid penetration, damaging the barrier properties of non-woven materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

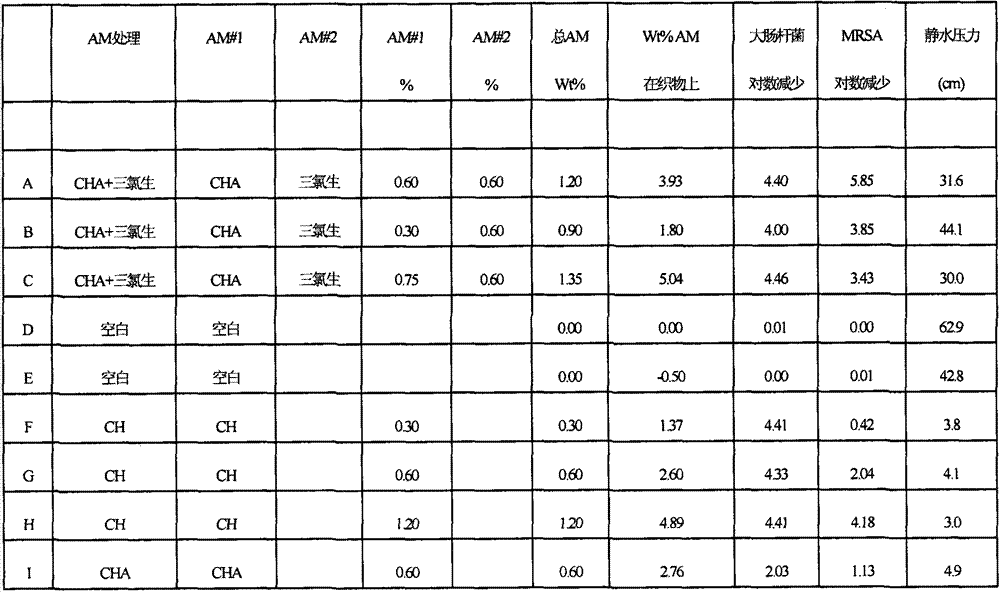

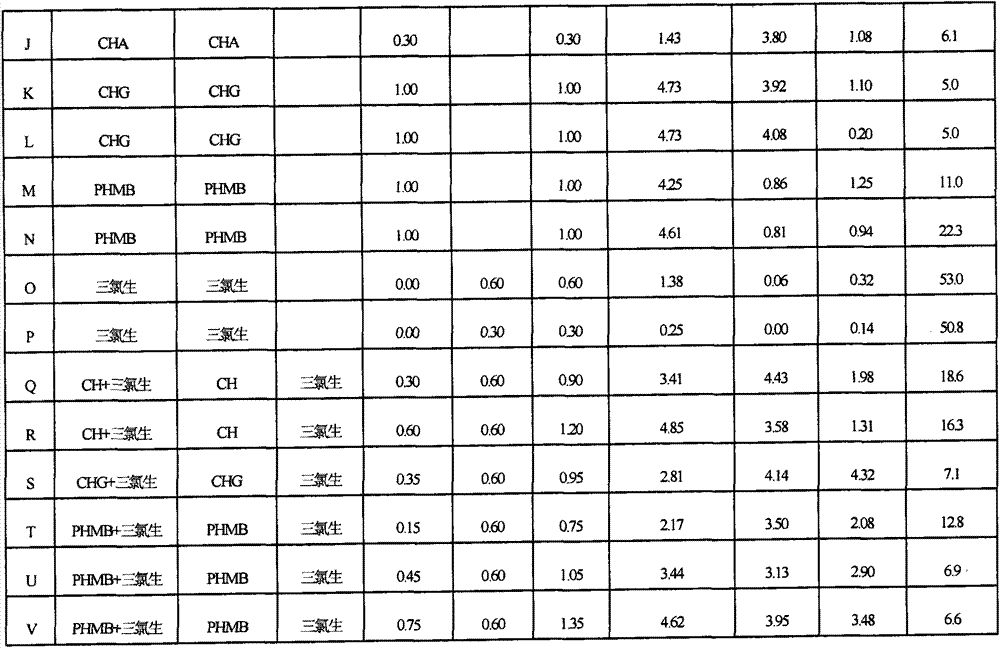

[0026]Experiments were performed to compare the effect of the combination of chlorhexidine acetate (CHA) and triclosan with: (1) each of chlorhexidine free base (CH), chlorhexidine acetate, chlorhexidine gluconate alone (CHG), polyhexamethylene biguanide (PHMB) and triclosan, (2) each combination of CH and triclosan, CHG and triclosan, and PHMB and triclosan. The following coating formulations were prepared with deionized water and sprayed onto 8 x 8 inch fabric samples of 34 gsm spunbond / meltblown / spunbond (SMS) nonwovens using a disposable atomizing hand sprayer.

[0027] - Formulation A: CHA (0.6% w / w), Triclosan (0.60% w / w) and ethanol (70%)

[0028] - Formulation B: CHA (0.3% w / w), Triclosan (0.60% w / w) and ethanol (70%)

[0029] - Formulation C: CHA (0.75% w / w), Triclosan (0.60% w / w) and ethanol (70%)

[0030] - Formulation D: no coating control

[0031] - Formulation E: ethanol (70%)

[0032] - Formulation F: CH (0.30% w / w) and ethanol (70%)

[0033] - Formulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com