Lathe adapter used for fine bar processing

A technology of adapters and thin rods, which is applied in the direction of metal processing equipment, automatic/semi-automatic lathes, metal processing machinery parts, etc., can solve problems such as trembling, large processing errors of thin rod workpieces, and economic losses, etc., to prevent Trembling phenomenon, guaranteed processing accuracy, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

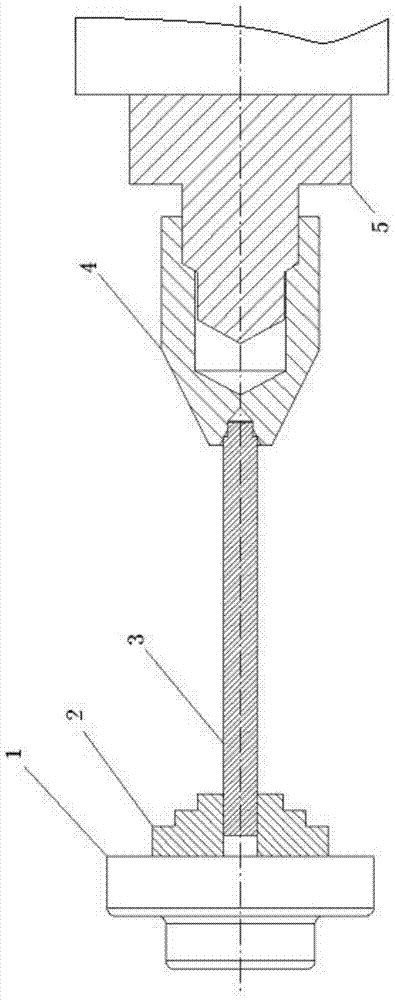

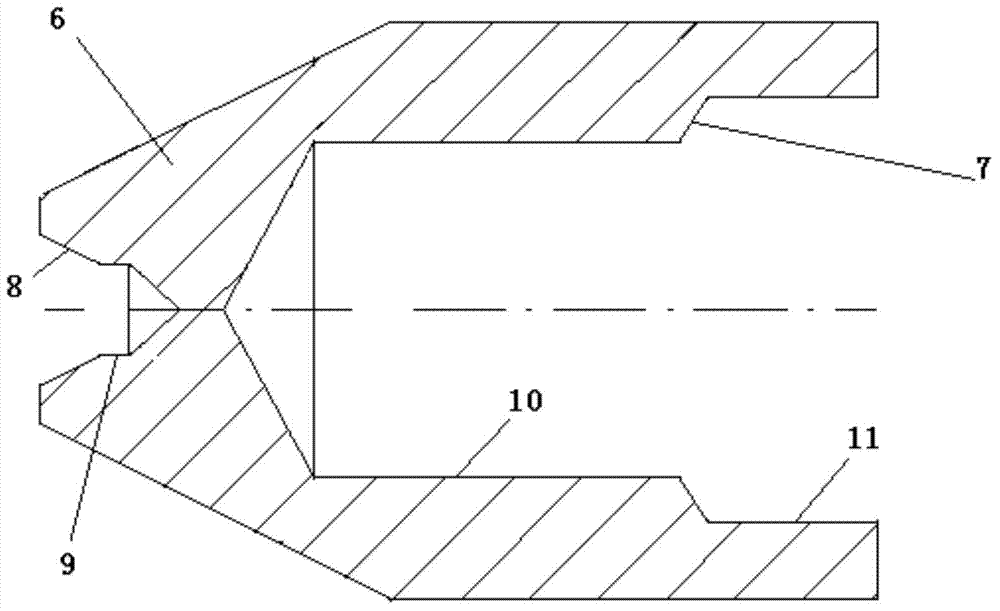

[0021] like Figure 1~2 As shown, a lathe adapter for thin rod processing, the left end of the adapter 4 is connected to the thin rod workpiece 3, the right end is connected to the lathe thimble 5, the left end of the adapter 4 is provided with a trapezoidal protrusion 6, and the right end is provided with There are inner stepped holes 10 and outer stepped holes 11 with different diameters. The surface of the trapezoidal protrusion 6 is provided with a tapered groove 8 , and the bottom of the tapered groove 8 is also provided with a cylindrical groove 9 .

[0022] The connection between the inner step hole 10 and the outer step hole 11 is provided with a slope 7. When connecting with the lathe thimble 5, the slope 7 fits with the step of the lathe thimble 5, and is used for the adjustment of the adapter 4 relative to the lathe thimble 5. position. The inner stepped hole 10 is a clearance fit with the head of the lathe thimble 5, and the outer stepped hole 11 is a transition f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com