Proportional pressure reducing valve of autocrane

A proportional pressure reducing valve and truck crane technology, applied in the field of automotive pressure reducing valves, can solve the problems of large volume and weight, unfavorable vehicle layout, etc., and achieve the effect of small size, convenient layout, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

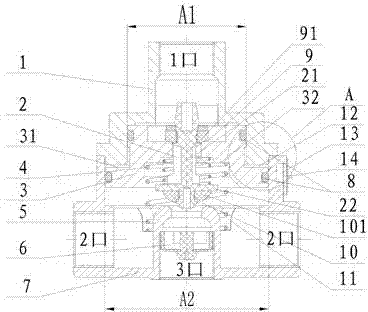

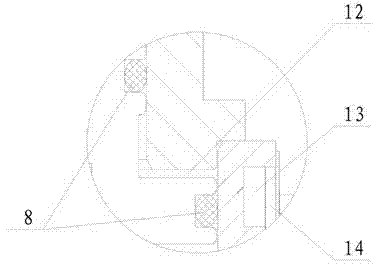

[0022] figure 1 and figure 2Among them, a proportional pressure reducing valve for a truck crane, including a valve body, a piston assembly 3, a valve assembly 2, an air inlet 1, an air outlet 2, and an exhaust port 3, and an upper valve connected up and down the valve body body 1 and lower valve body 7, the air inlet 1 is located on the top of the upper valve body 1, and the piston assembly 3 is provided with a step 31, the area of the front end surface of the piston assembly 3 is smaller than the area of the rear end surface, and the area of the piston assembly 3 The area of the front end is A1, the area of the rear end surface is A2, a sealing ring 8 is arranged between the piston assembly 3 and the inner wall of the valve body, and the upper and lower parts of the step 31 of the piston assembly 3 are respectively connected with the inner walls of the upper valve body 1 and the lower valve body 7. There is a sealing ring 8, and the outer wall of the piston assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com