Repeatedly detachable buckle structure

A technology of snap-fit structure and snap-window, applied in the direction of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of customer repair difficulties, waste of resources, and difficulty in disassembly, and achieve easy installation and disassembly, reducing Maintenance cost, the effect of convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

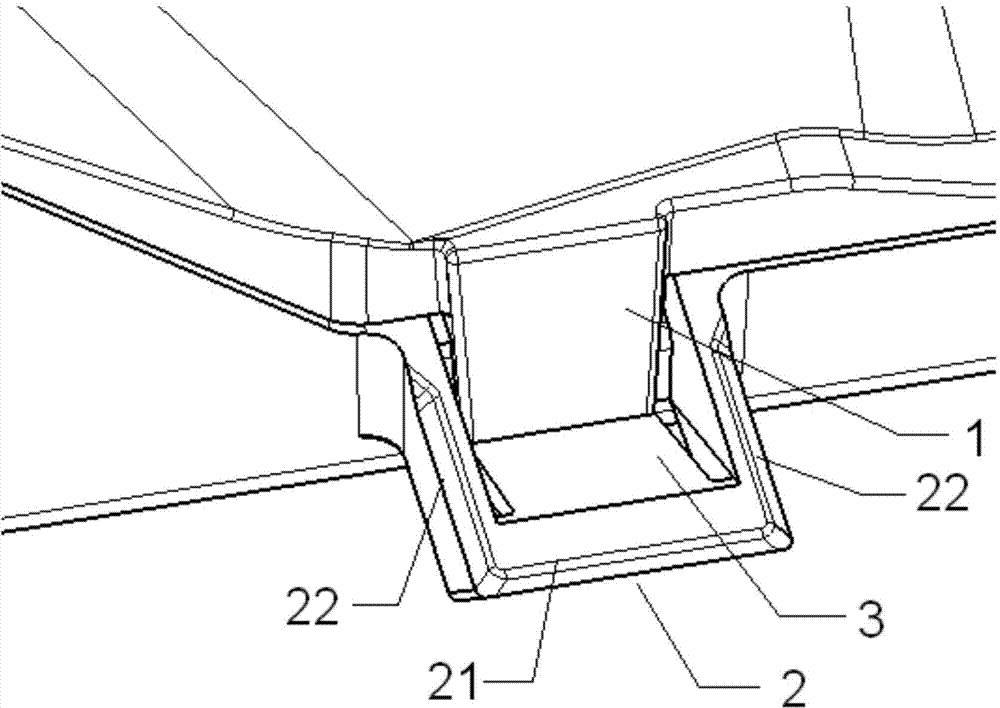

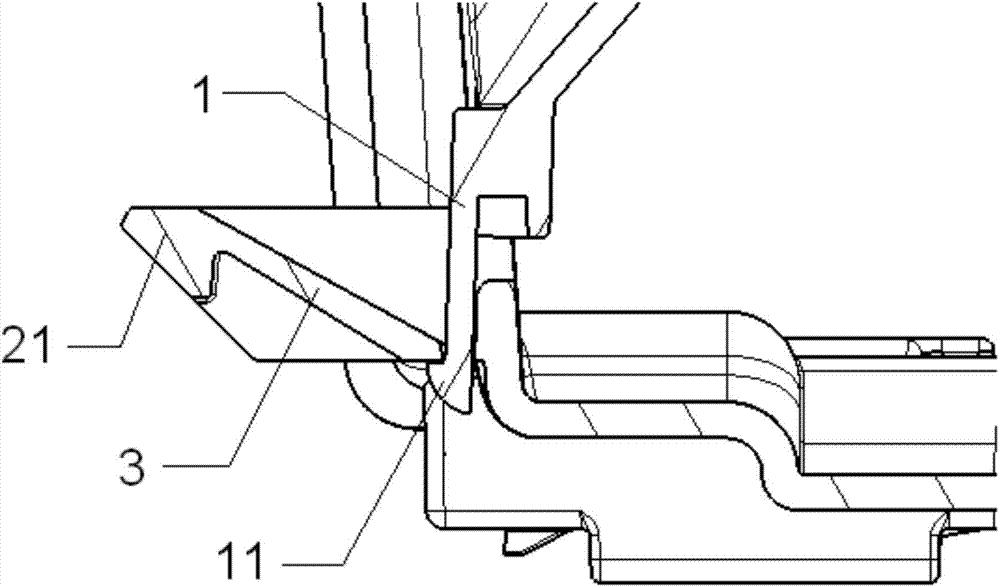

[0019] Such as figure 1 with figure 2 As shown, a buckle structure that can be disassembled repeatedly, the buckle structure is used for the buckle connection of the wire harness slot, and includes a nose 1 and a window 2 . The card nose 1 is a strip-shaped elastic part, so that it can produce a certain deformation under the action of an external force, and its end is bent to one side to form a buckle head 11, which is used to fasten the buckle structure, and the card window 2 includes A push arm connecting part 21 and two wire groove connecting parts 22 that are respectively connected to the two ends of the pushing arm connecting part, the pushing arm connecting part 21 is fixed on the wire harness groove by the wire groove connecting part 22, and the pushing arm connecting part 21 is provided with There is a card window push arm 3, the root of the card window push arm 3 is connected to the push arm connecting part 21, and the end of the card window push arm 3 abuts against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com