Winder for binding cable binding wire

A cable winder and wire binding technology, which is applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of inflexible finger movement, loose and tight wire binding, gaps, and short distances, so as to save manual operation intensity and tie The coil is strong and tight, and the effect of saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

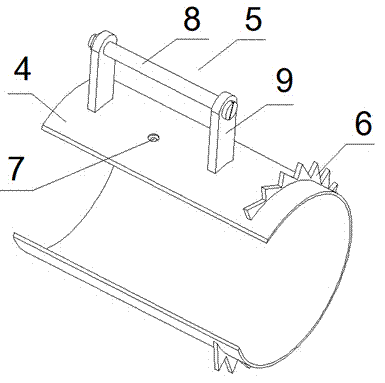

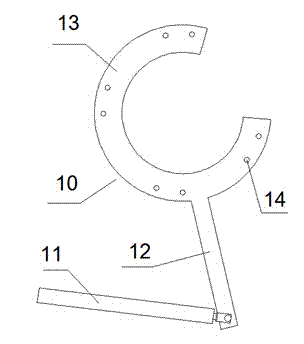

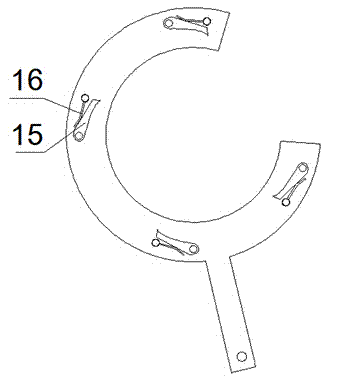

[0027] Winders for bundling cable ties such as Figure 4 As shown, the wire winder includes a ratchet part 2 and a pawl part 3, and the ratchet part 2 and the pawl part 3 are arranged correspondingly. like figure 1 As shown, the ratchet part 2 includes a sleeve 4 with a notch on one side. A support 5 is arranged on the outer surface of the sleeve 4. The support 5 is used to set up the binding shaft 1. The wall of the sleeve 4 corresponds to the bottom of the support 5. A circular hole 7 for passing the binding wire wound on the binding shaft 1 is provided at the corresponding position, and the bracket 5 is located at a position close to the side opening of the sleeve 4 . The bracket 5 includes two opposite side plates 9 and a cross arm 8 , the cross arm 8 is a screw with a nut, and the cross arm 8 is connected between the two side plates 9 . The outer circumference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com