yarn feeder

A yarn feeder and yarn feeding wheel technology, applied in textile and papermaking, knitting, weft knitting and other directions, can solve the problems of complex production and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

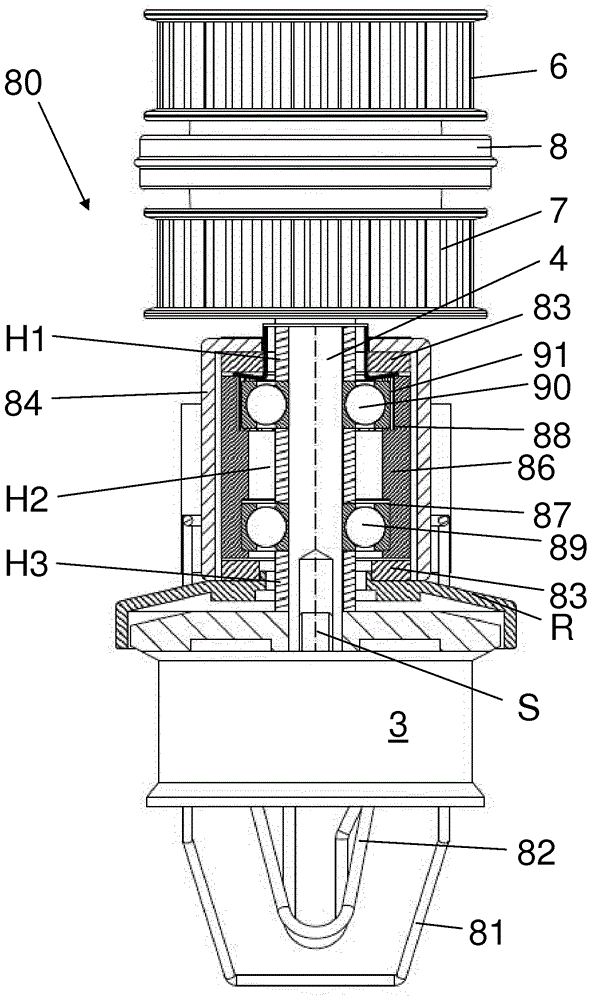

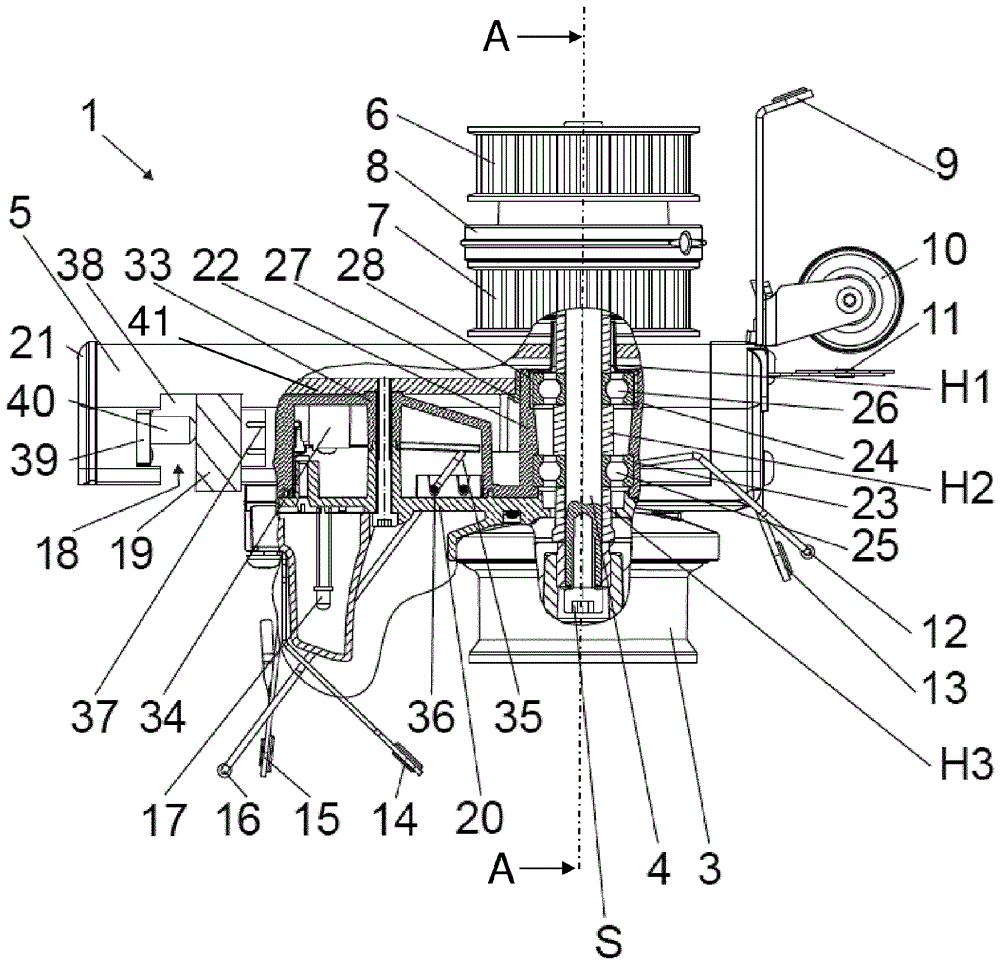

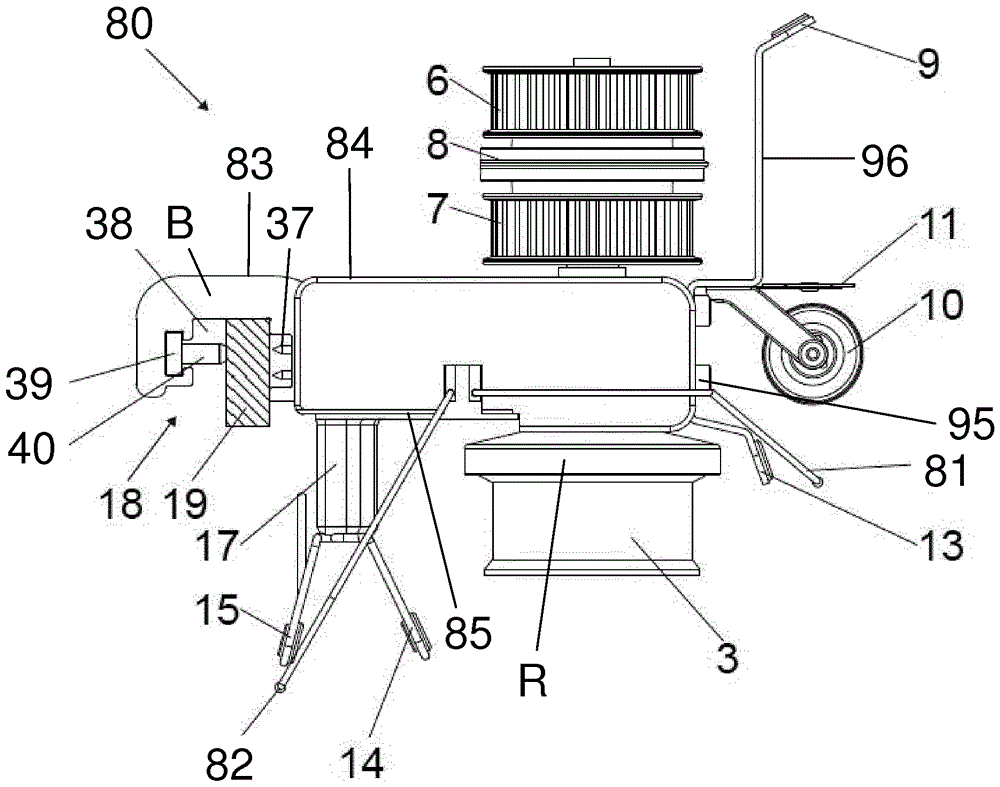

[0074] first example

[0075] Figures 1 to 3 A first example of a yarn feeder 1 according to the invention is shown for delivering yarn 2 to a textile machine, in particular a circular weaving machine. The yarn feeder 1 has a yarn feed wheel 3 and a drive shaft 4 . The yarn feed wheel 3 is fixed on the textile machine in such a way that the drive shaft 4 (that is to say its axis of rotation) extends vertically. The yarn feeding wheel 3 is arranged at the drive shaft 4 .

[0076] The yarn feeder 1 comprises a carrier 5 for supporting the drive shaft 4 and for fixing the yarn feeder 1 at the textile machine.

[0077] The yarn feeding wheel 3 is fixed on the lower end of the drive shaft 4 with a bolt S.

[0078] At the upper end of the drive shaft 4 at least one (preferably a plurality) of belt pulleys 6 , 7 is arranged. Between the pulleys 6 , 7 there is at least one coupling disc 8 or other coupling means. The belt pulleys 6 , 7 are rotatably mounted on the drive shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com