Controller assembly and cab for operation machinery

A technology for operating machinery and controllers, which is applied in the field of controller assemblies and cabs for operating machinery, which can solve the problems of reduced space for configuring controllers, difficulties in equipment assembly, and repairs, and achieve the effect of easy repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

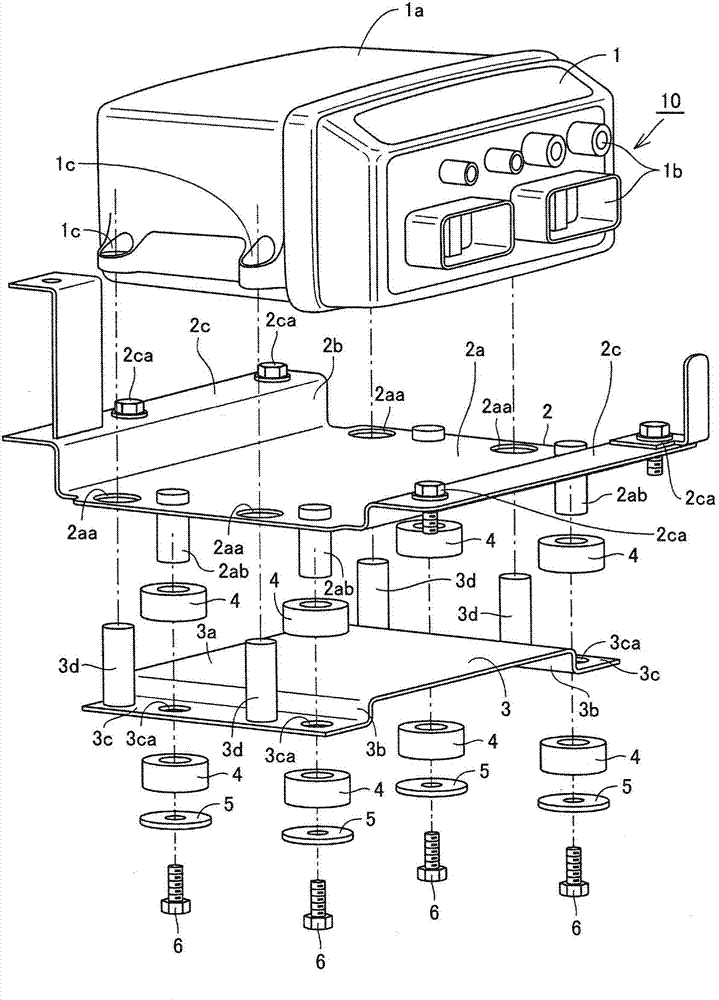

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the present invention will be described based on the drawings.

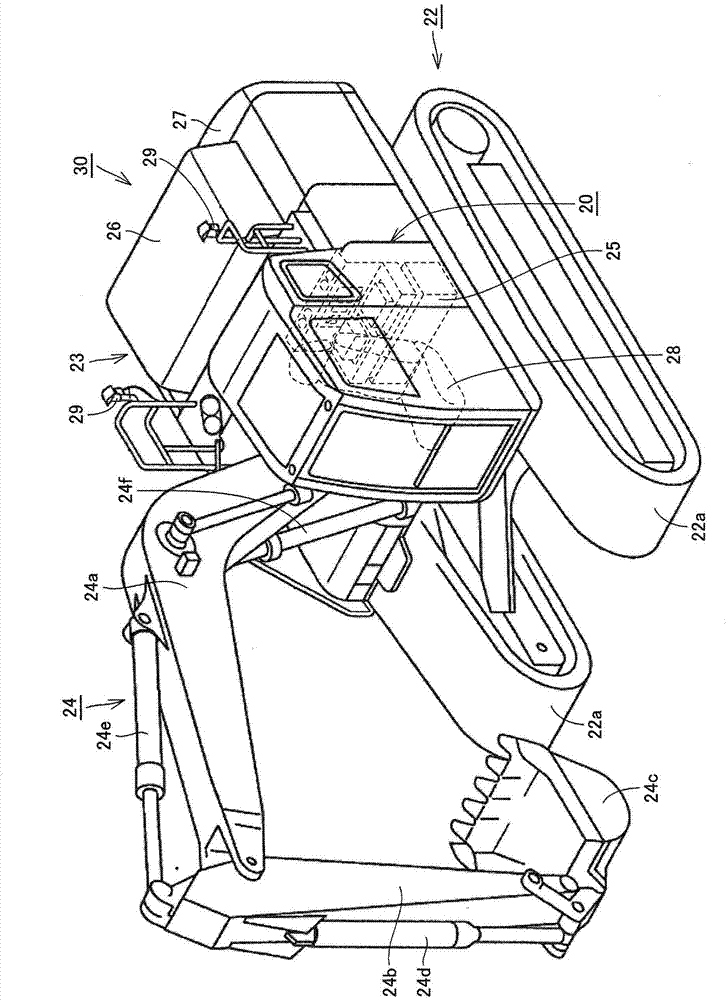

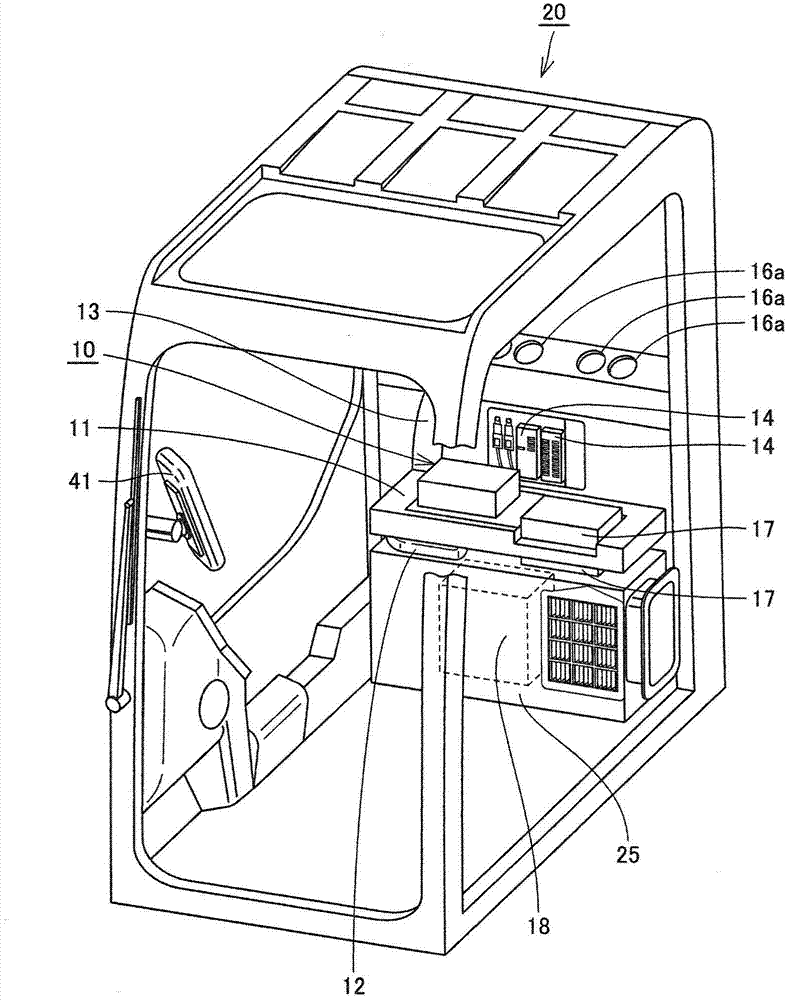

[0039] First, the configuration of a work machine according to an embodiment of the present invention will be described. Hereinafter, as an example of a work machine to which the idea of the present invention can be applied, use figure 1 and figure 2 A hydraulic excavator and a cab used for the hydraulic excavator will now be described. It should be noted that the present invention can also be applied to work machines having a cab, such as bulldozers and wheel loaders, in addition to hydraulic excavators.

[0040] figure 1 It is a perspective view schematically showing the structure of a hydraulic excavator according to an embodiment of the present invention. figure 2 yes means figure 1 Partial enlarged perspective view of the cab of the hydraulic excavator.

[0041] Such as figure 1 As shown, the hydraulic excavator 30 mainly includes a lower traveling body 22 , an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com