screw pump

A screw pump, screw technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve limited and other problems, achieve uniform mass distribution, avoid downtime, and increase the delivery volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

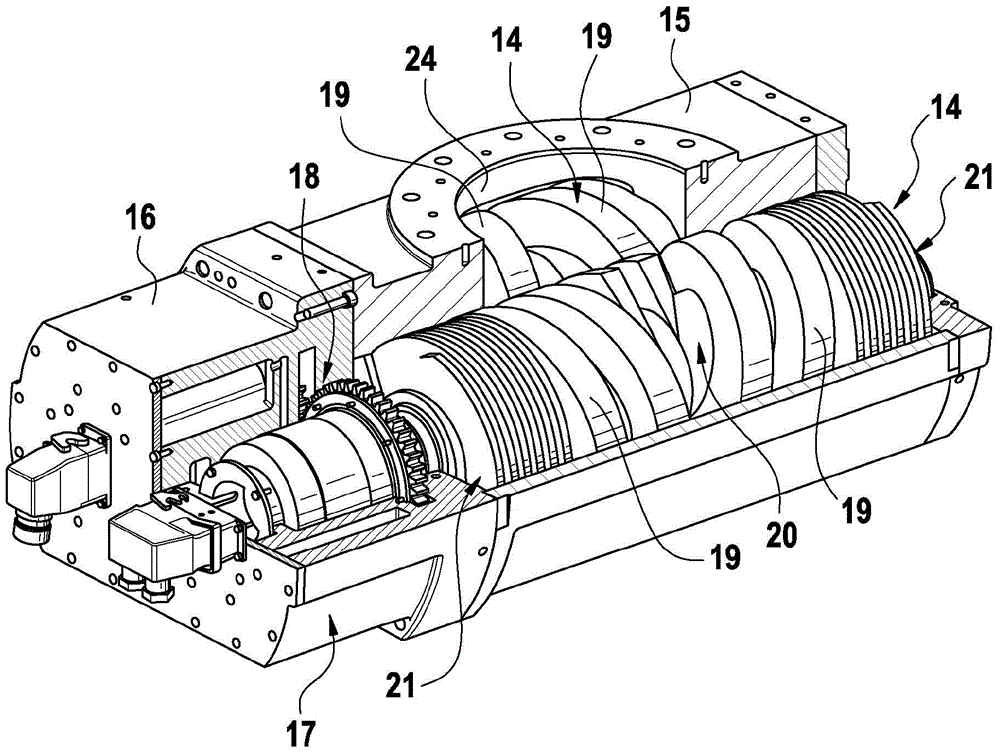

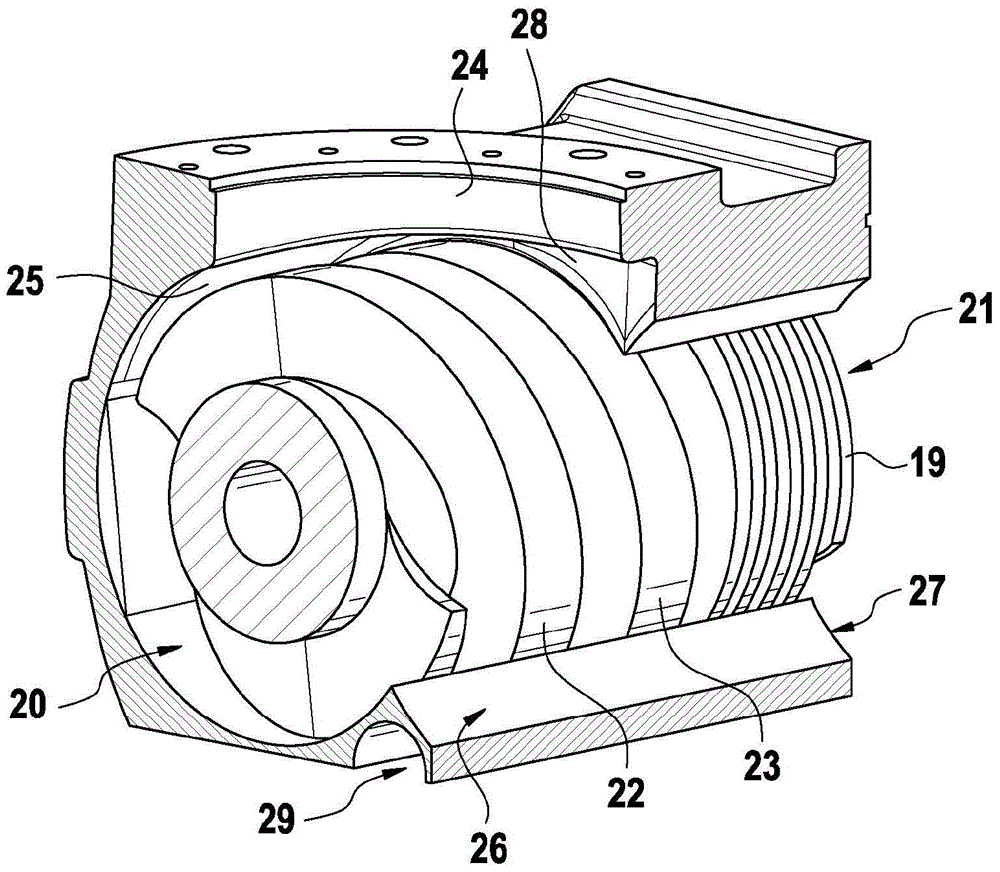

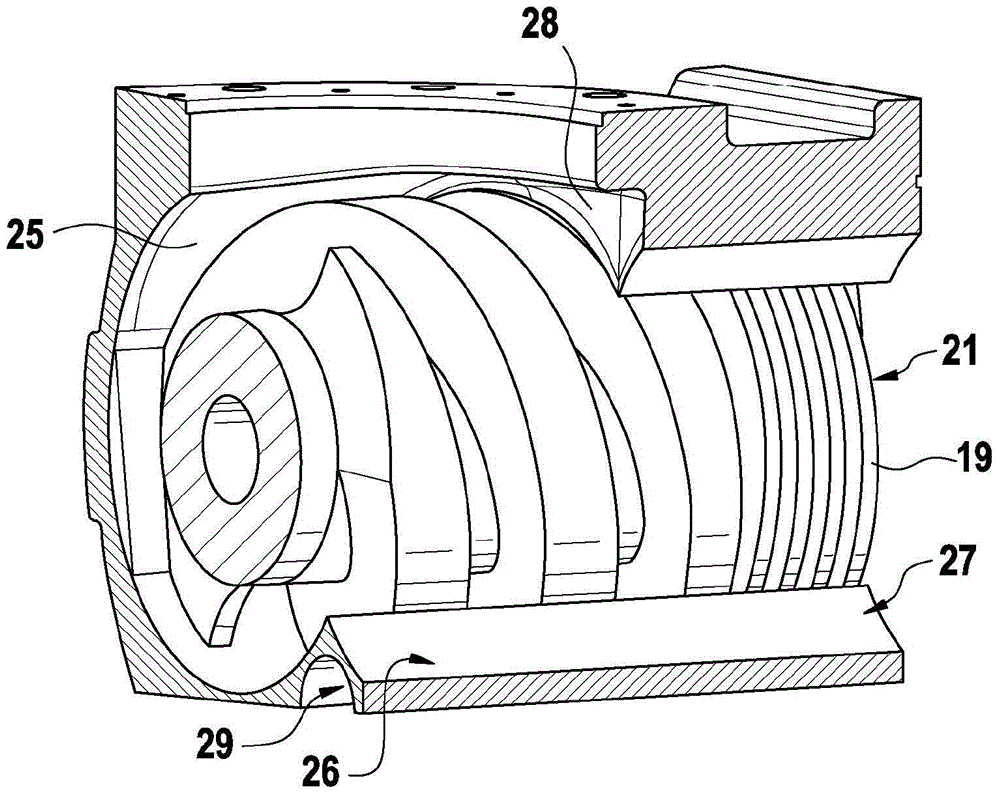

[0036] figure 1 In this case, the pump of the present invention comprises two screw rods 14 housed in a pump housing 15 . Due to the not fully shown pump housing 15 , one of the screw rods 14 can be seen in full length, while the other screw rod 14 is substantially covered by the pump housing 15 . The two screws 14 engage each other, which means that the threaded protrusions of one screw 14 engage into the recesses between the two threaded protrusions of the other screw 14 .

[0037] The pump comprises a control and drive unit 16 in which an electrically controlled drive motor 17 is provided for each screw 14 . The electronic controller of the drive motor 17 is arranged so that the two screws 14 run perfectly synchronously with respect to each other, and the thread protrusions of the screws 14 do not touch. In addition, each screw 14 is equipped with a gear 18 as a safety measure against damage to the screws 14 . The gears 18 engage each other, causing a positive coupling o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com