High-efficiency double-screw compressor main engine

A twin-screw and compressor technology, applied in the direction of machines/engines, mechanical equipment, rotary piston machinery, etc., can solve the problem of no identical or similar products, and achieve simple structure, convenient mass production and reduced area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

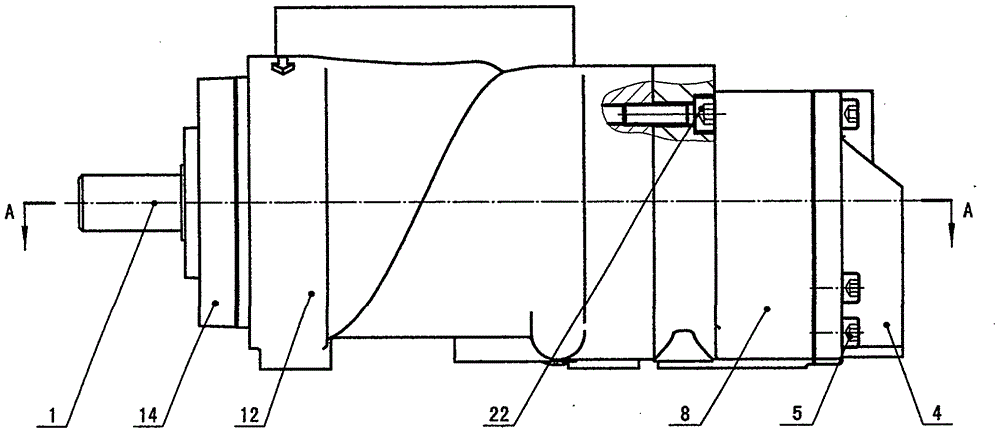

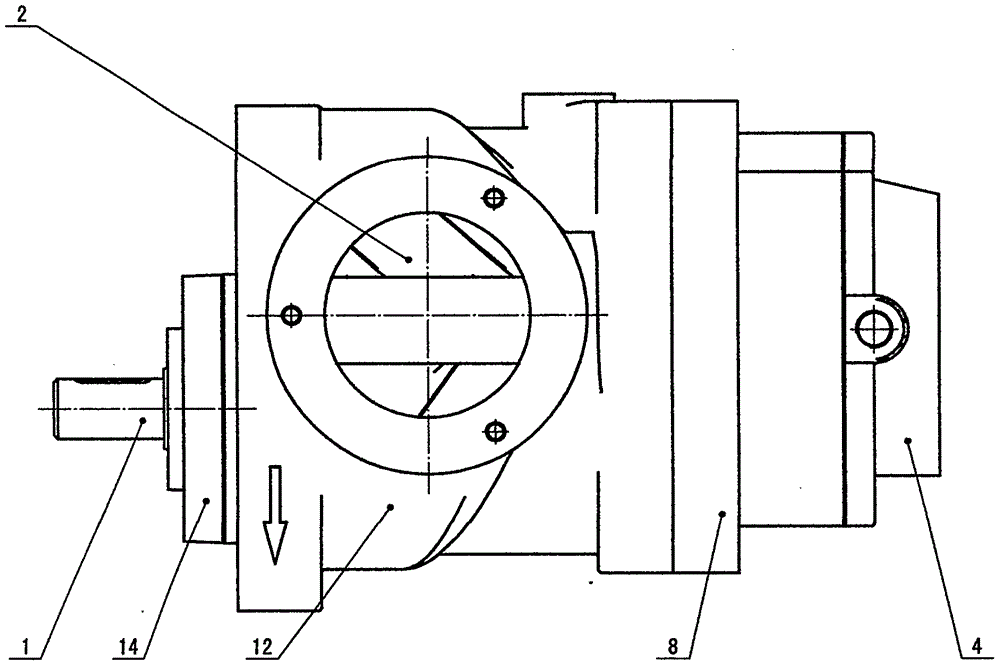

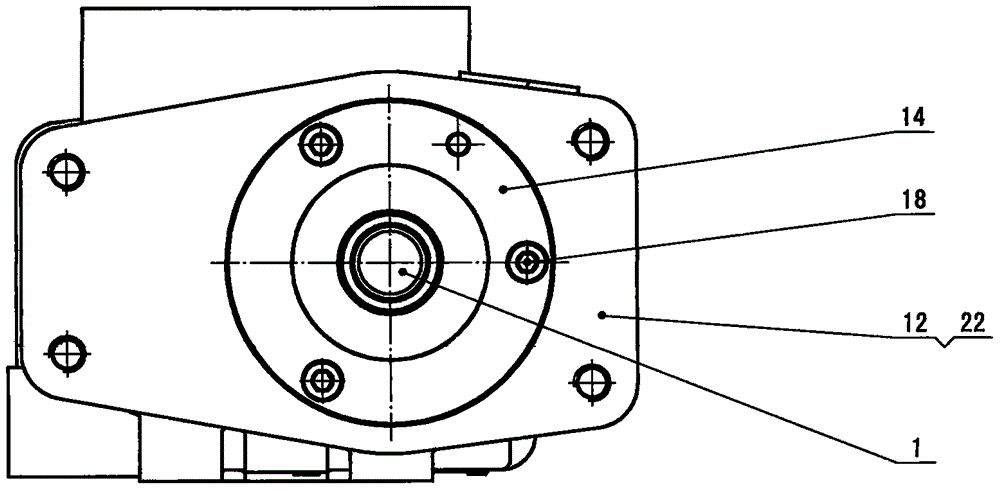

[0017] combine figure 1 , figure 2 , image 3 and Figure 4 , a high-efficiency twin-screw compressor host, including a male rotor (1), a female rotor (2), a round nut (3), a rear end cover (4), a screw (5), a bearing (6), a bearing (7 ), support (8), cylindrical pin (9), female rotor sleeve (10), male rotor sleeve (11), box (12), bearing (13), front end cover (14), bearing (15 ), shaft seal (16), shaft sleeve (17), screw (18), gasket (19), O-ring (20), (gasket) 21, screw (22).

[0018] Box (12), support (8), front end cover (14), rear end cover (4), shaft seal (16), gasket (19), gasket (21), screw (5), screw ( 18), screws (22) and O-rings (20) together constitute a sealed box, the inside of the sealed box is provided with male and female screw rotors, and the male rotor (1) and the male rotor sleeve (11) are fixedly connected to the Together, the leads of the male rotor (1) and the male rotor bushing (11) are different, the lead of the male rotor (1) is greater than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com