A production system of polypropylene composite material for automotive interior

A technology for composite materials and automotive interiors, which is applied in the field of polypropylene composite material production systems for automotive interiors, can solve the problems of reducing VOC content, difficulty in cutting materials, and low VOC removal efficiency, so as to reduce VOC content and improve processing Efficiency, the effect of increasing the amount of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

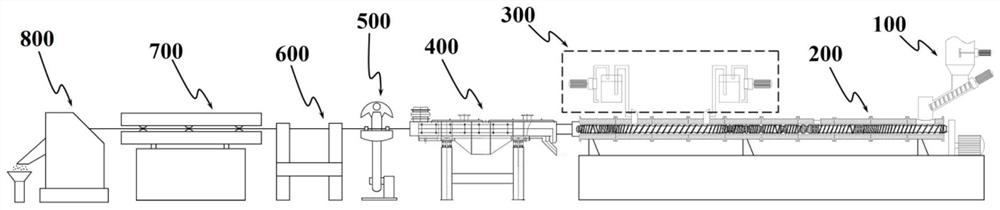

[0042] to combine Figure 1~4 , a polypropylene composite material production system for automotive interiors in this embodiment includes a feeding unit 100 , an extrusion unit 200 , a vacuum unit 300 , a traction unit 700 and a pelletizing unit 800 .

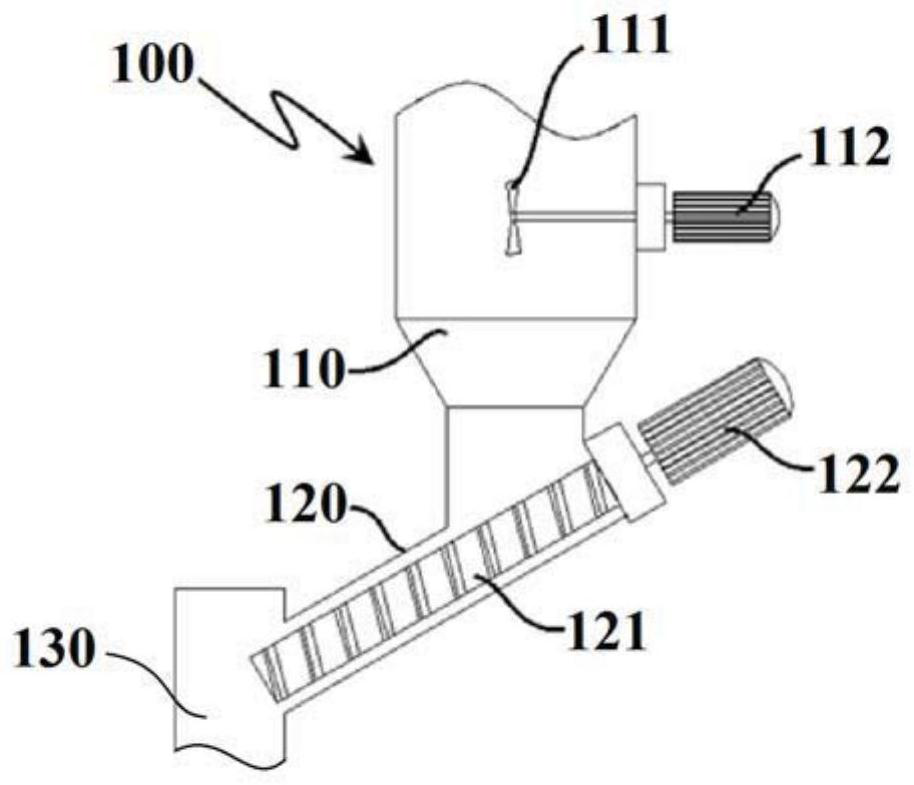

[0043] The feeding unit 100 includes a hopper 110, the lower part of the hopper 110 is provided with a feeding trough 120, and the feeding screw 121 is arranged obliquely in the lower feeding chute 120, and the lower part of the feeding chute 120 is connected with a feeding port 130; the feeding screw 121 passes through the feeding motor 122 drive, the angle a between the feeding screw 121 and the horizontal direction is 15° to 45°, and in this embodiment, the angle a=30°, the set inclination angle can effectively avoid the occurrence of light-weight or highly-filled mixtures in the hopper 110 No blanking, difficult blanking and bridging phenomenon, and the inclined feeding screw 121 has no dead angle, which avoids the accumula...

Embodiment 2

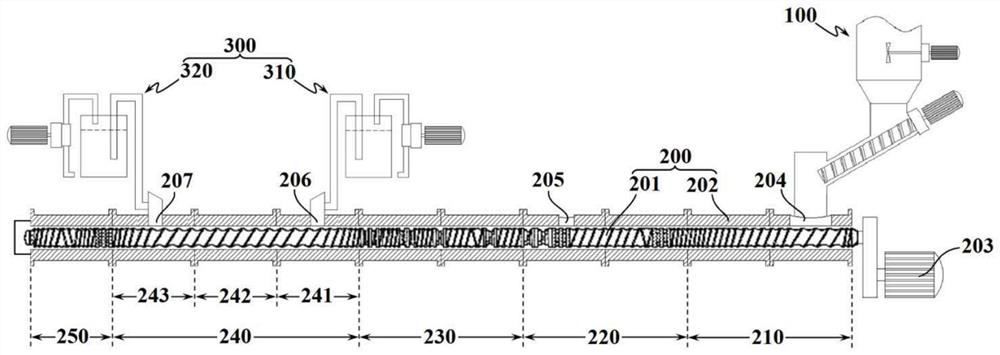

[0052] to combine Figure 1~4 , a kind of polypropylene composite material production system for automobile interior decoration of the present embodiment, comprises feeding unit 100, extruding unit 200 and vacuumizing unit 300; Extruding unit 200 comprises feeding screw 201 and barrel 202, and feeding screw 201 is set In the barrel 202; the extrusion unit 200 includes a solid conveying section 210, a melting section 220, a reaction section 230 and a vacuum exhaust section 240 along the movement direction of the mixture. In addition, the barrel 202 of the extrusion unit 200 moves along the mixture There are 10 heating zones in sequence, which are the 1st to 10th heating zones. It should be noted that since the compound is a gradual transition process between the various processing stages in the extrusion unit 200, the extrusion unit 200 The corresponding relationship between each segment and each heating zone is a rough correspondence, not an absolute correspondence in spatial ...

Embodiment 3

[0075] The content of this embodiment is basically the same as that of Embodiment 1, except that in the vacuum exhaust section 240, the temperature of the seventh heating zone in this embodiment is 227°C, the temperature of the eighth heating zone is 197°C, and the temperature of the ninth heating zone is The zone temperature is 197°C, that is, the temperature of the 8th heating zone is the same as that of the 9th heating zone, so that the temperature of the mixture when passing through the buffer section 242 can be quickly and steadily reduced to the same temperature as the temperature of the 9th heating zone, so that the subsequent two The vacuuming of the stage vacuum 320 is more stable to the removal process of VOC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com