Electronic mechanical brake device for railway vehicle

An electromechanical braking and rail vehicle technology, applied in the direction of braking transmissions, brakes, vehicle components, etc., can solve the problems of large brake size and low output efficiency, reduce volume, reduce production costs, and ensure braking force output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

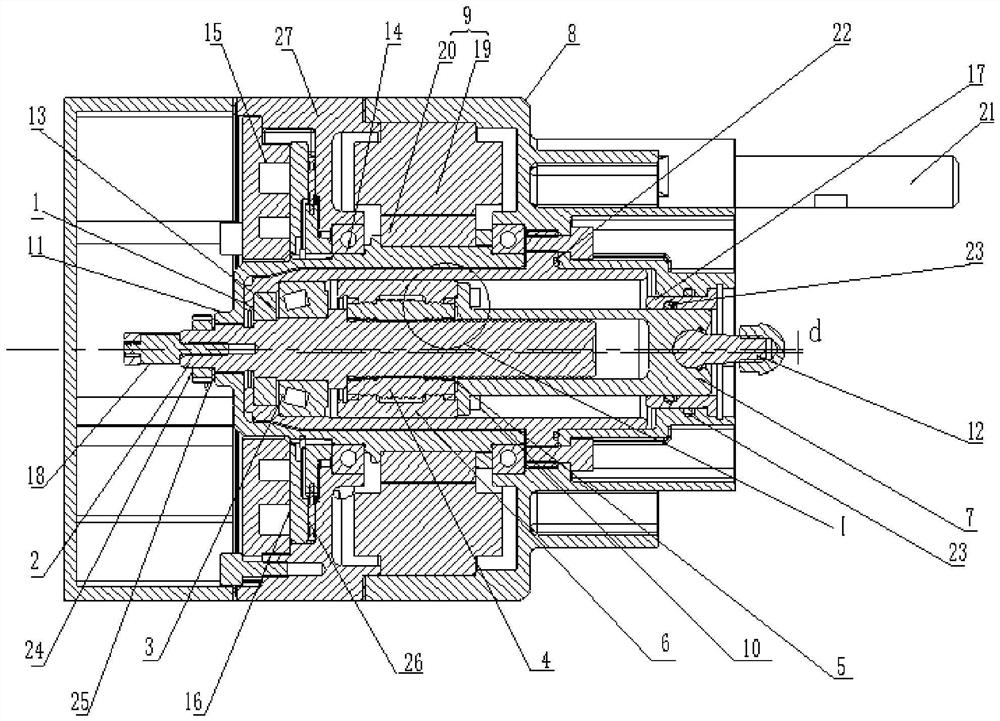

[0071] Such as figure 1 and figure 2 As shown, the present embodiment is an electromechanical brake device for rail vehicles, including a drive motor 9, a fixed sleeve 1, a planetary roller mechanism, a front housing 8, an output shaft 7 and a clutch lock mechanism.

[0072] The front housing 8 is connected to the front end of the fixed sleeve 1 to form a cavity, and an O-ring 22 is arranged at the joint between the front housing 8 and the fixed sleeve 1; the cavity is partially filled with lubricating oil or grease.

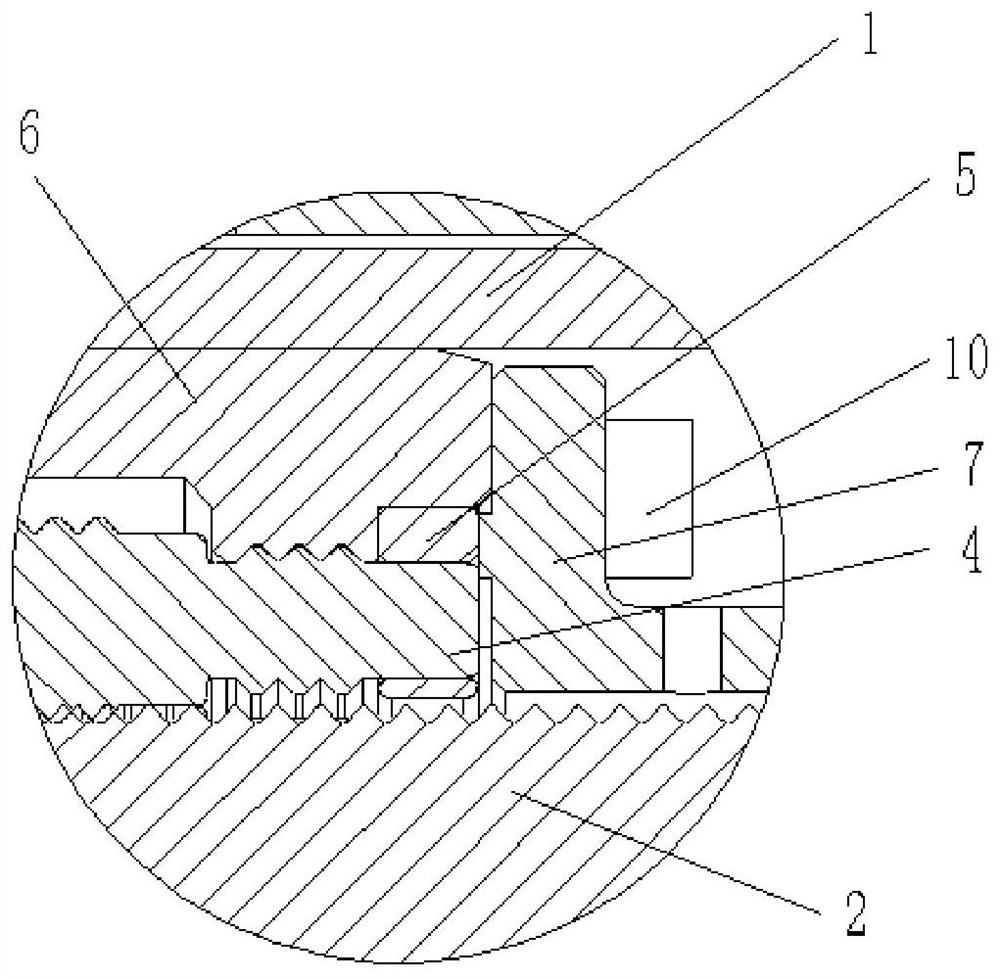

[0073] Such as image 3 and Figure 4 As shown, the planetary roller mechanism includes an input shaft 2, two positioning rings 5, a roller frame 6 and N planetary rollers 4, N is an integer greater than 2, and N in this embodiment is 6; the input shaft 2 is arranged in the cavity and Coaxial with the fixed sleeve 1, a cone bearing 3 is provided between the output shaft 7 and the inner wall of the fixed sleeve 1, and the cone bearing 3 is located at the rear...

Embodiment 2

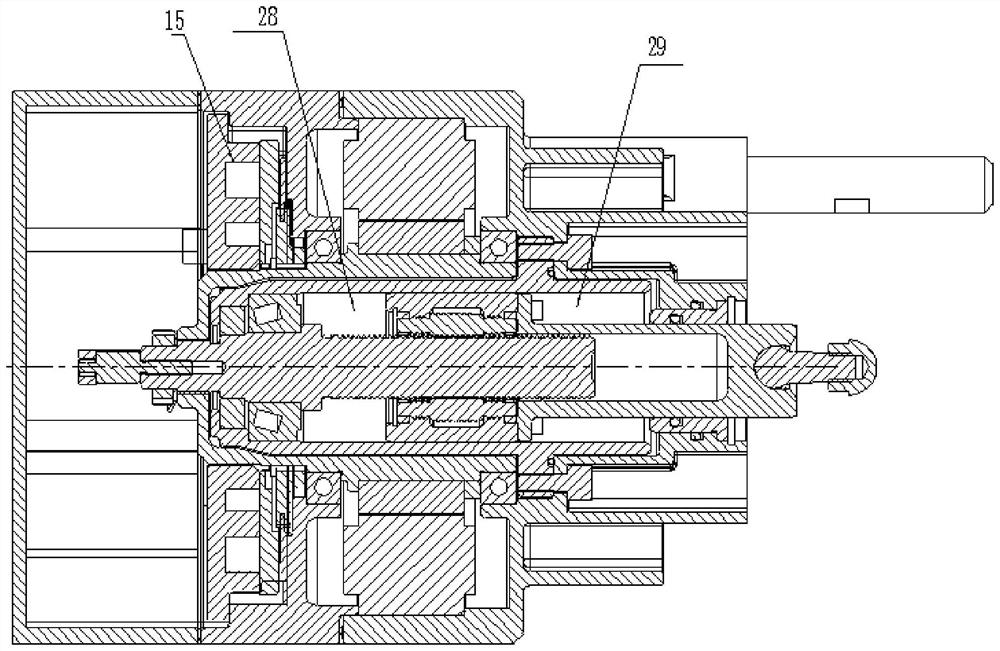

[0085] The difference from Embodiment 1 is that the driving motor 9 is a double motor, such as Figure 5 As shown, in this embodiment, the dual motors adopt coaxial dual stators and single rotor to realize design redundancy and improve the reliability of the overall equipment. In other embodiments, the double motors may also adopt a coaxial double stator and double rotor structure.

Embodiment 3

[0087] The difference from the first embodiment is that the front end of the input shaft 2 is provided with a plurality of first annular grooves at equal intervals, and the middle part of the planetary roller 4 is provided with an external thread matching the first annular grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com