Sterilization furnace for edible fungus culture material

The technology of culture material and sterilization furnace is applied in the field of sterilization furnace for edible fungus culture material, which can solve the problems of unsatisfactory sterilization effect, energy loss, labor switching for workers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

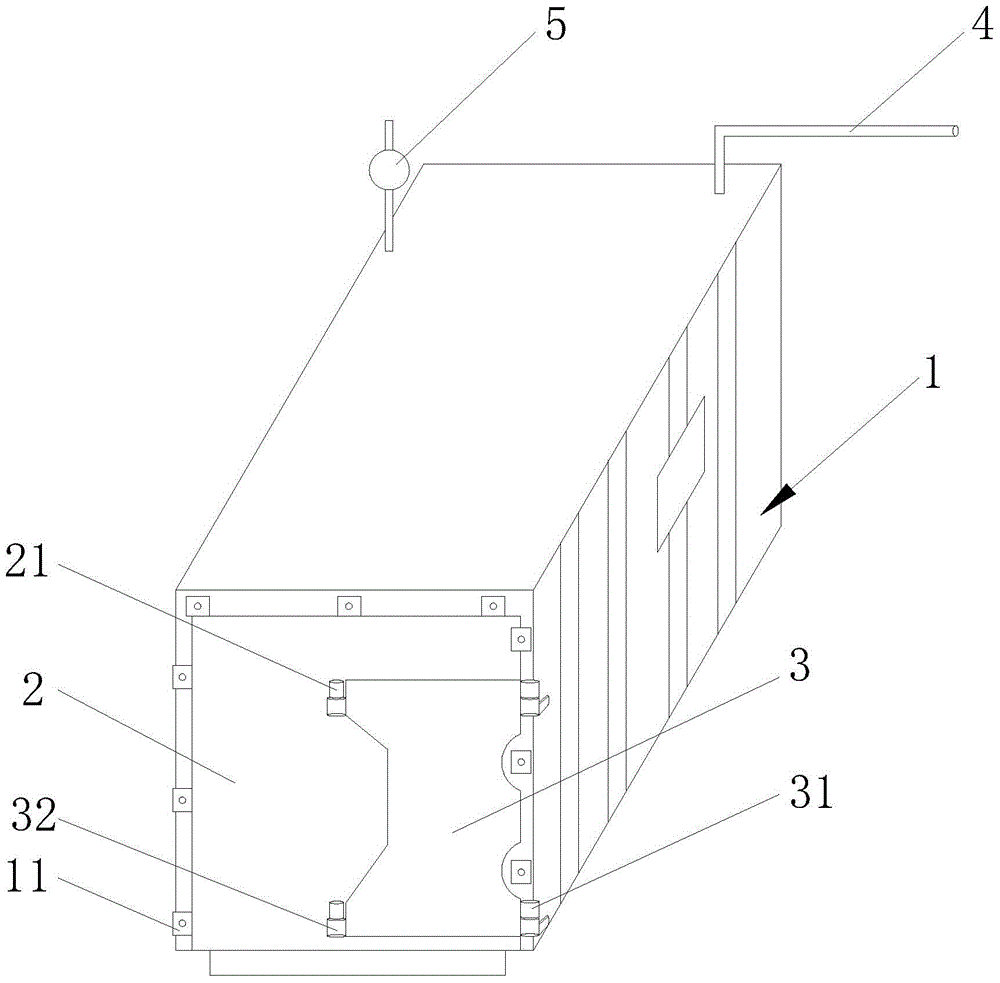

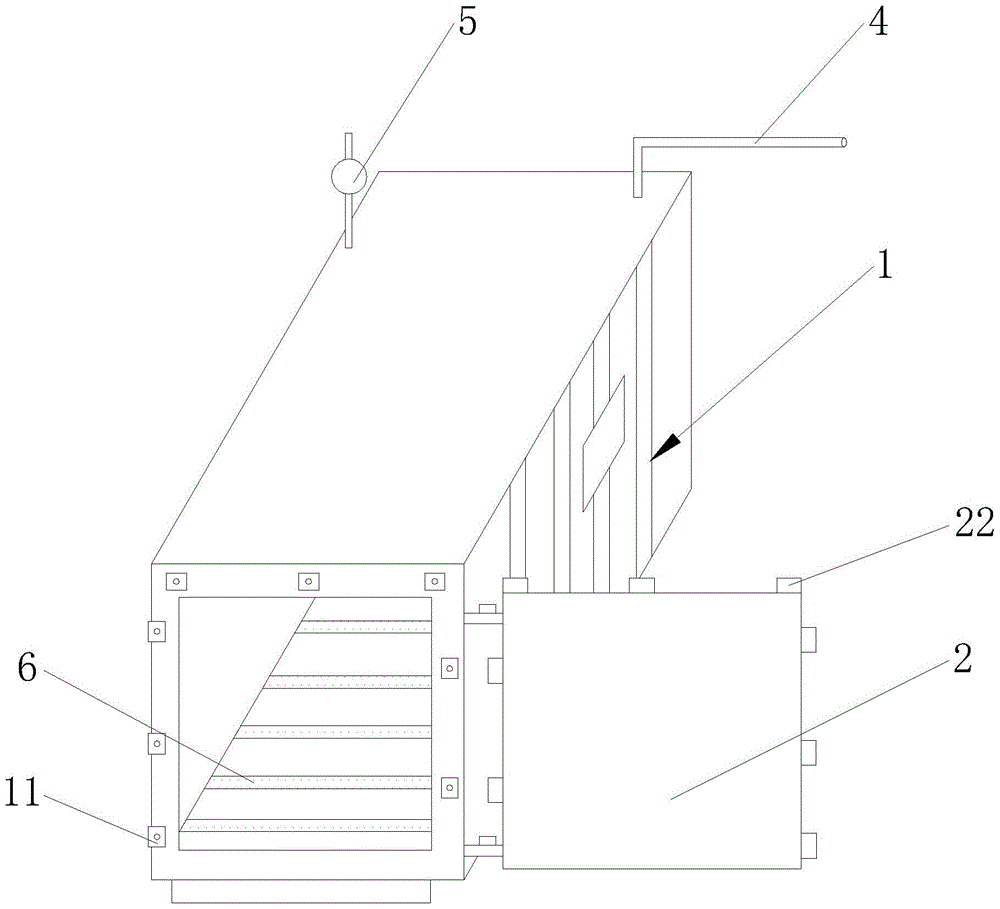

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] see picture 1 As shown, a sterilizing furnace for edible fungus culture material includes a furnace body with an inner cavity 1 , installed in the furnace body 1 upper furnace door 1 The bottom row of the inner chamber is equipped with a steam pipe for providing sterilizing steam 6 , in the furnace body 1 There is also a layer of thermal insulation material wrapped on the outer circumference of the furnace body. 1 There is also an exhaust pipe on the exhaust gas 4 . The furnace door includes a large furnace door 2 , and located in the big furnace door 2 small outer door 3 , the small furnace door 3 One side is provided with the furnace body 1 pivoted hinge 31 , small furnace door 3 There is a bearing seat on the other side 32 , big furnace door 2 A shaft arranged longitudinally throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com