Rapid food cooking device and rapid cooking method thereof

A cooking device and rapid evaporation technology, applied in the fields of food science, steam cooking utensils, cooking utensils, etc., can solve the problems of lack of use experience, large energy loss, insufficient food powder, etc., to speed up the cooking process and reduce energy loss. , the effect of shortening the pre-cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

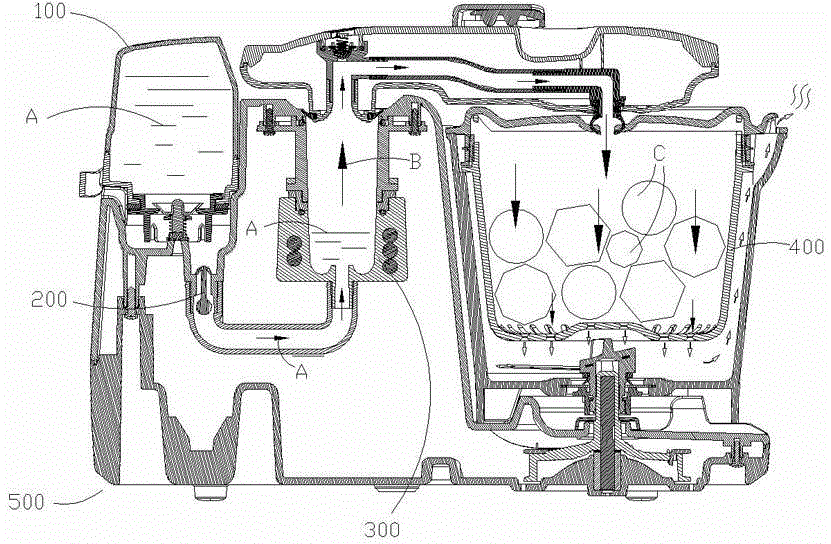

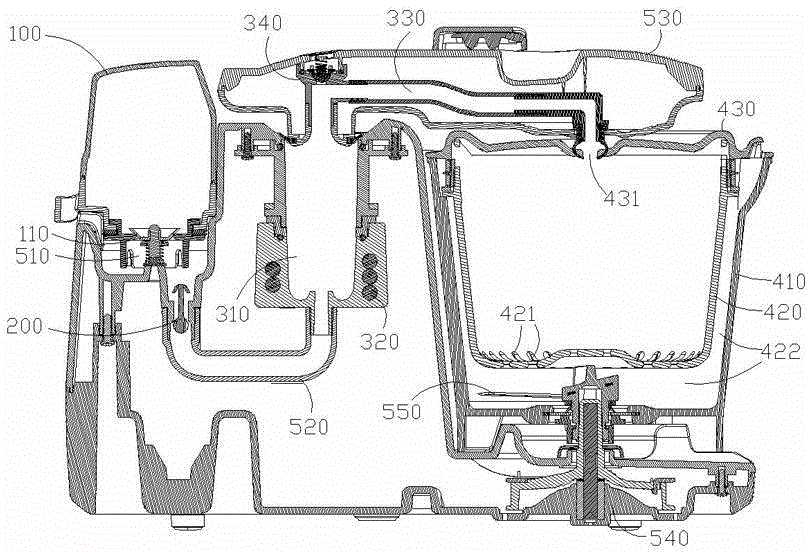

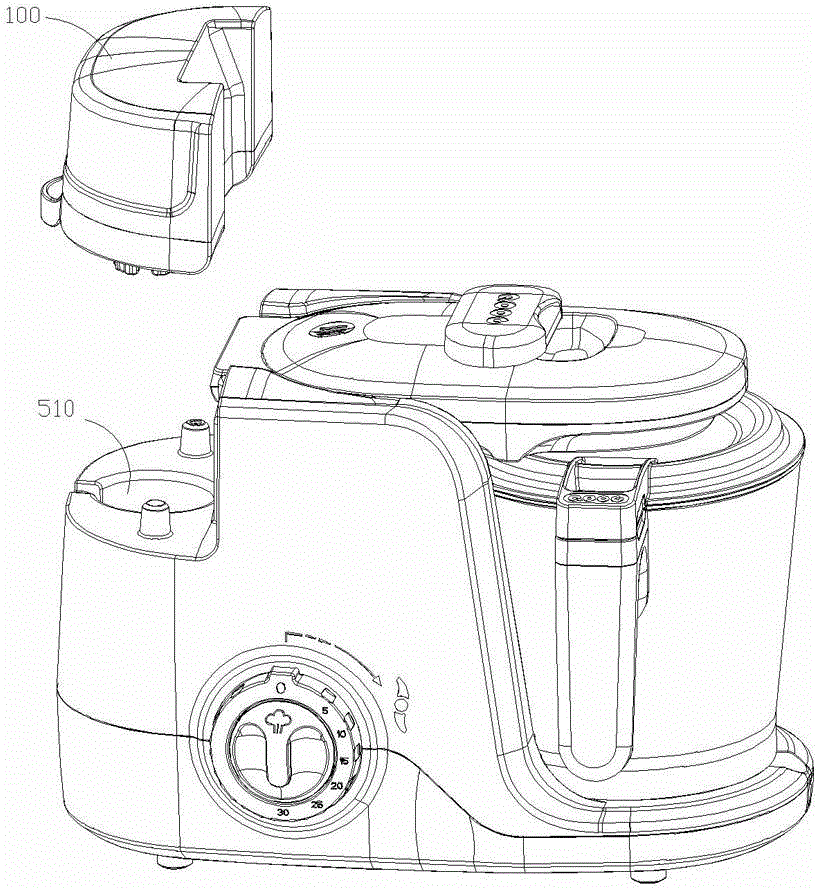

[0034] like Figures 1 to 8 As shown, a fast food cooking device includes a self-contained water tank 100, a non-return unit 200, a fast evaporation unit 300 and a cooking unit 400, wherein the self-contained water tank 100 is used to accommodate steam generation water A, and the self-contained water tank The water A for steam generation in 100 is supplied quantitatively to the fast evaporation unit 300 from time to time. The free-standing water tank 100 can be conveniently filled with water, and its internal water volume can be intuitively observed by the user. At the same time, with the help of the structural design of the free-standing water tank 100, the rapid food cooking device can repeatedly add water without Need to stop, does not affect the function of normal cooking work.

[0035] The fast evaporating unit 300 receives the quantitative steam-generating water A supplied from the independent water tank 100, and the steam-generating water A is rapidly heated to the boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com