Electric heating pedestal toilet board and production method thereof

A production method and electric heating technology, applied in the field of sanitary ware, can solve problems such as difficult fixing of heating wires, overheating, and easy misalignment, and achieve the effects of convenient maintenance and replacement, reduced use costs, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

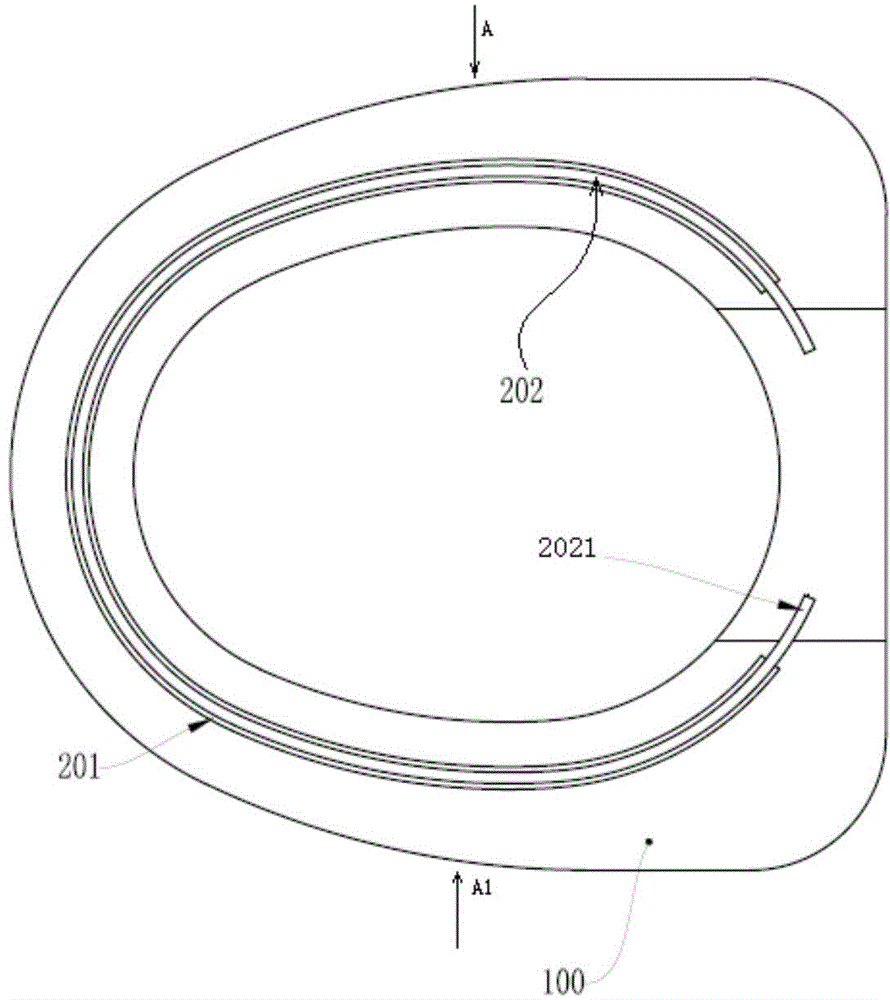

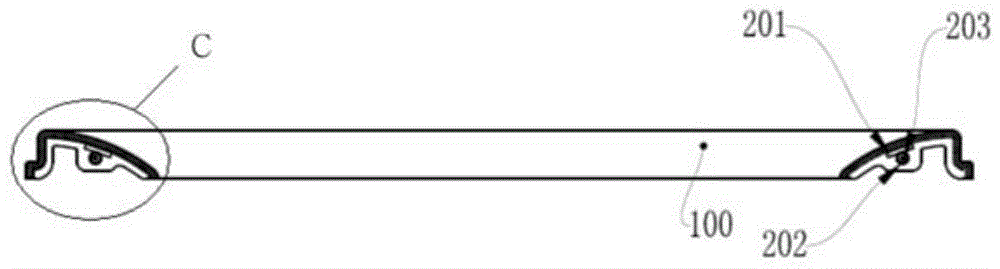

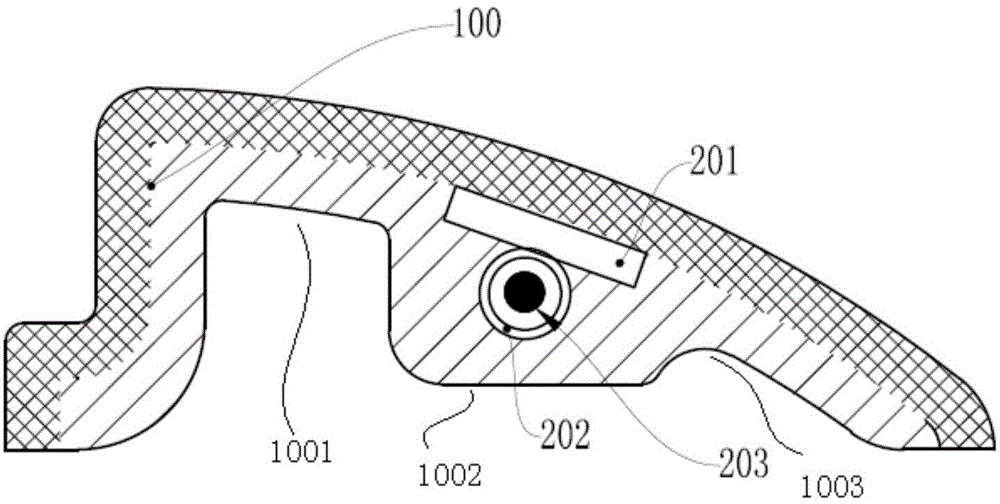

[0029] Refer to attached Figure 1-3 , In this implementation, an electric heating toilet seat is provided, which includes a pad body 100; a heat conduction device built in the pad body; The rear end of the body is disconnected; a heating wire 203 is installed in the hollow metal tube 202; the heating wire is connected to a power junction box (not shown on the figure). With the above structure, the heat is conducted through the heat conduction device. When the power is turned on, the toilet seat will heat rapidly and evenly. In the above structure, the heating wire 203 can be easily replaced. When the heating wire 203 is damaged, it only needs to be replaced. 203 out, and then put in a new one.

[0030] In the electric heating toilet seat provided in this embodiment, the hollow metal tube 202 is located at the lower part of the metal bottom plate 201, and a section of both ends of the hollow metal tube 202 protrudes from the metal bottom plate 201 The surplus portion 2021, f...

Embodiment 2

[0037] When people use the toilet, the front end of the toilet seat usually has no contact, so it is meaningless to heat the front end, and some toilet seats are U-shaped at the front end. In view of the above situation, the present invention provides another embodiment, that is, the heat conduction device is arranged as a structure disconnected at the front end of the pad body.

[0038] Specifically, see the attached Figure 4 And attached Figure 5 , an electric heating toilet seat, which includes a pad body 100; a heat conduction device built in the pad body 100; the heat conduction device has a hollow structure; a movable and detachable heating wire 203 is installed in the hollow structure; The heating wire 203 is connected with a power junction box (not shown in the figure); In the metal tube 202, the hollow metal tube 202 is located at the lower part of the metal bottom plate 201, and the heating wire 203 is drawn out from the end of the hollow metal tube 202; the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com