A rapid destroying device for gas generators of automobile air bags

A gas generator and automobile safety technology, applied in the direction of solid waste removal, blasting, etc., can solve the problems of unsafe operation and low efficiency, and achieve the effect of safe destruction, rapid destruction, and prevention of splashing of the gas generator shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

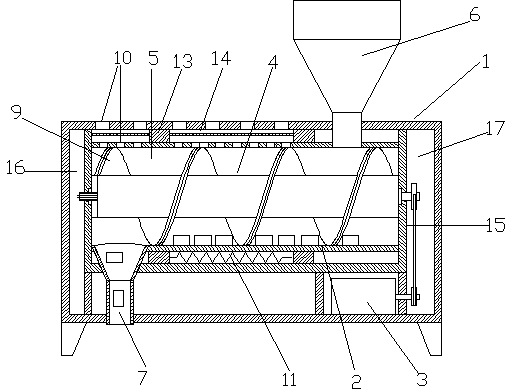

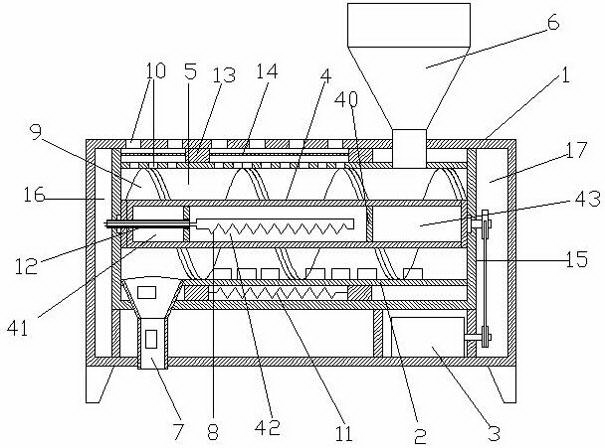

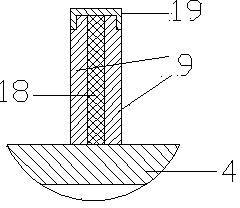

[0020] Such as figure 1 and figure 2 A kind of automobile safety airbag gas generator rapid destruction device shown, comprises explosion-proof box body 1, is provided with explosion-proof cylinder 2 in the explosion-proof box body, is provided with rotating cylinder 4 driven by motor 3 in the explosion-proof cylinder, explosion-proof cylinder 2, rotating cylinder The axis of cylinder 4 is distributed horizontally. An annular cavity 5 is provided between the rotating cylinder and the explosion-proof cylinder. The explosion-proof box is provided with a feed hopper 6 at the right end of the explosion-proof cylinder. The discharge end of the feed hopper communicates with the ring cavity. The explosion-proof box The bottom of the body is located at the left end of the explosion-proof cylinder, and a discharge hopper 7 is provided. The lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com