Chain hoist artificial single-point synchronous traction equipment and construction method

A technology of chain hoists and traction equipment, which is applied in bridge construction, erection/assembly of bridges, bridges, etc., which can solve the problems of difficult access of large machinery and equipment, narrow venues, and inconvenient transportation, and achieves the benefits of implementation, convenient transportation, and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and specific embodiments.

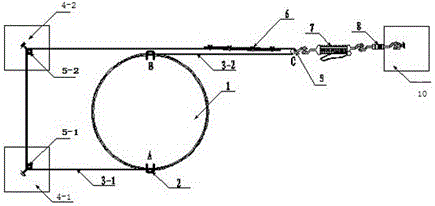

[0023] like figure 1 As shown, a chain hoist artificial single-point synchronous traction equipment includes a turntable 1, a traction ring 2, a section A 3-1 of a steel wire rope, a section B 3-2 of a steel wire rope, a guide concrete anchor pile, and a chain hoist concrete anchor pile 10 , fixed pulley, U-shaped bolt 6, chain hoist 7, tension gauge 8 and pulley 9, the fixed pulley is fixed on the guide concrete anchor pile, the traction pull ring 2 is respectively set on the A end and B end of the turntable 1, and the tension gauge 8 is connected to Between the chain hoist concrete anchor pile 10 and the chain hoist 7 , the chain hoist 7 is connected with a pulley 9 .

[0024] According to the direction of rotation of the turntable 1, the winding direction of the section A 3-1 of the steel rope and the section B 3-2 of the steel rope around the turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com