Assembling type enhanced steel-wood buckling constraint support with tapping screws

A technology of self-tapping screws and buckling restraints, which is applied to building components, earthquake resistance, etc., can solve the problems affecting the production efficiency of buckling restraint supports, self-heaviness, and long maintenance time, so as to overcome the easy damage caused by tension, reduce earthquake damage, reduce Effect of Construction Workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

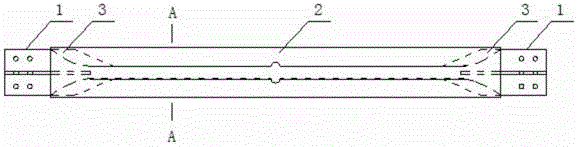

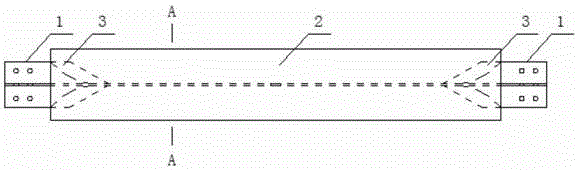

[0021] Such as figure 1 As shown, an assembled steel-wood buckling-constrained support reinforced with self-tapping screws includes a core material 1, a peripheral constraint 2, an unbonded material or an air layer 3, and the unbonded material or air layer 3 is arranged on Between core material 1 and peripheral constraint 2;

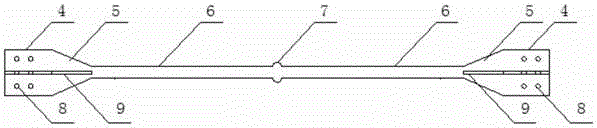

[0022] The core material 1 includes a connecting section 4, a transition section 5, a core working section 6, a limit card 7 and a stiffening plate 9, the two ends of the core working section 6 are connected to the connecting section 4 through a transition section 5, and the core working section 6 is provided with a limit card 7 in the middle, the transition section 5 is arc-shaped, the connecting section 4 is provided with a connecting bolt hole 8, and the stiffening plate 9 is vertically installed in the middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com