Anti-slip screw

A technology of screws and screw caps, applied in the field of hardware components, can solve problems such as complexity and reduce work efficiency, and achieve the effect of anti-slip preload and increase preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

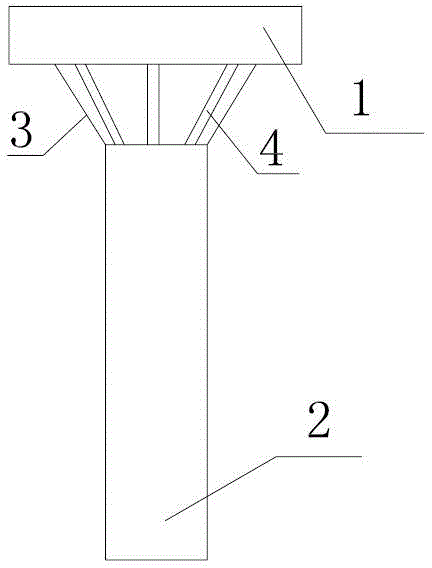

[0017] An anti-skid screw, comprising a screw cap 1 and a screw rod 2; a tapered transition section 3 is set between the screw cap 1 and the screw rod 2; the screw rod is in the shape of a cylinder; the tapered transition section 3 is in the shape of a truncated cone, The larger bottom surface of the truncated cone is connected to the screw cap 1, and the smaller bottom surface of the truncated cone is connected to the screw 2; the conical transition section is provided with a rib 4, and the rib is formed by the The surface of the tapered transition section is convexly formed.

[0018] The screw cap 1 is circular, and the radius of the screw cap is greater than the radius of the cross section of the screw. The radius of the larger bottom surface of the tapered transition section 3 is smaller than the radius of the screw cap 1 and greater than the cross-sectional radius of the screw 2; the smaller bottom surface radius of the tapered transition section 2 is equal to the radius ...

Embodiment 2

[0020] This embodiment is basically the same as Embodiment 1, the only difference being that the protrusion height of the rib 4 remains unchanged from the small end to the large end of the tapered transition section 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com