Shipborne cabin bottom valve

A bottom valve and marine technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve the problems of water valves in the cabin that cannot be fully discharged, recharge safety, seawater leakage, etc., to solve seawater recharge and prevent recharge Good effect of irrigation and use safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

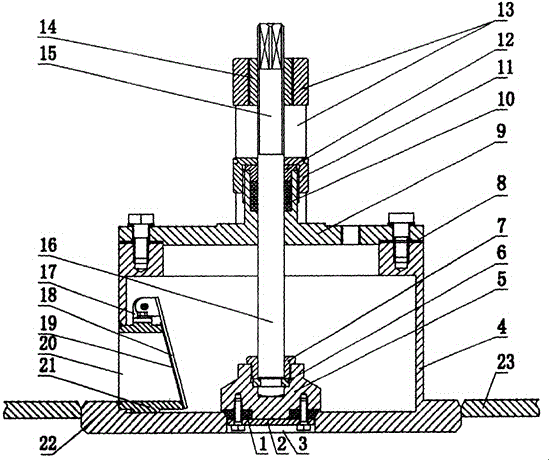

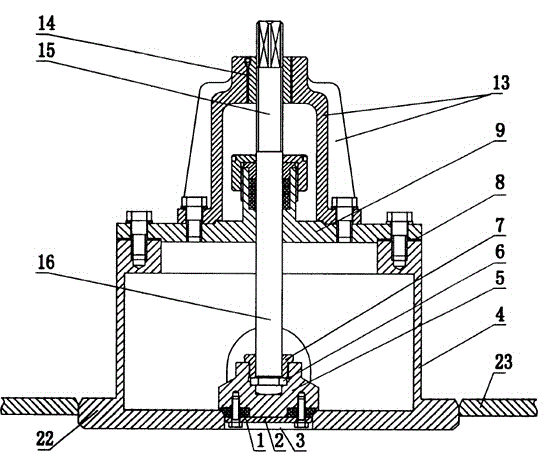

[0012] Refer to the attached figure 1 And attached figure 2 The marine full-row double-control bilge valve of the present invention is described in detail below.

[0013] The marine full-row double-control bilge valve of the present invention has a structure including a shell (4), a valve cover (9), a valve stem (16), a valve stem bracket (13), a sealing seat (5), and a baffle (2) , the sealing sleeve (21), the sealing plate (18), the bonnet (9) is set on the upper end of the housing (4) through the sealing ring (8), the valve stem bracket (13) is arranged on the bonnet (9), and the valve The upper end of the stem (16) is set in the stem bracket (13) through the stem nut (14), the middle part of the stem (16) passes through the valve cover (9), and passes through the sealing ring (10), packing pressure The sleeve (12), the gland nut (11) and the bonnet (9) are tightly connected together, and the lower end of the valve stem (16) extends all the way to the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com