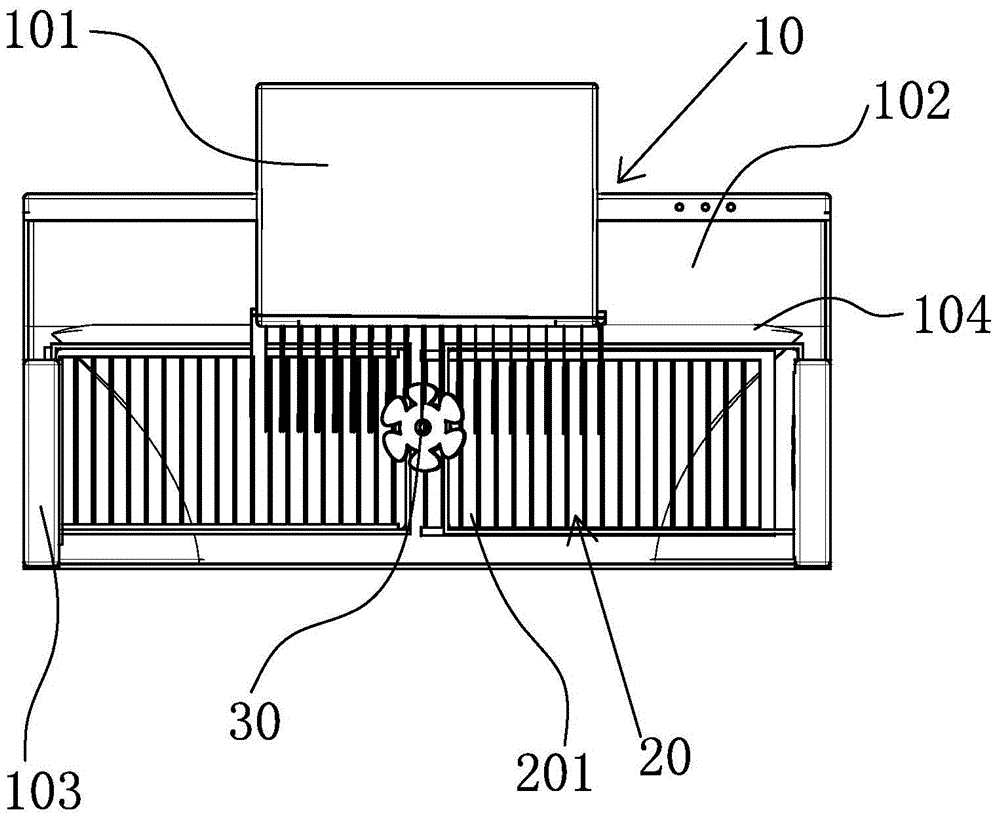

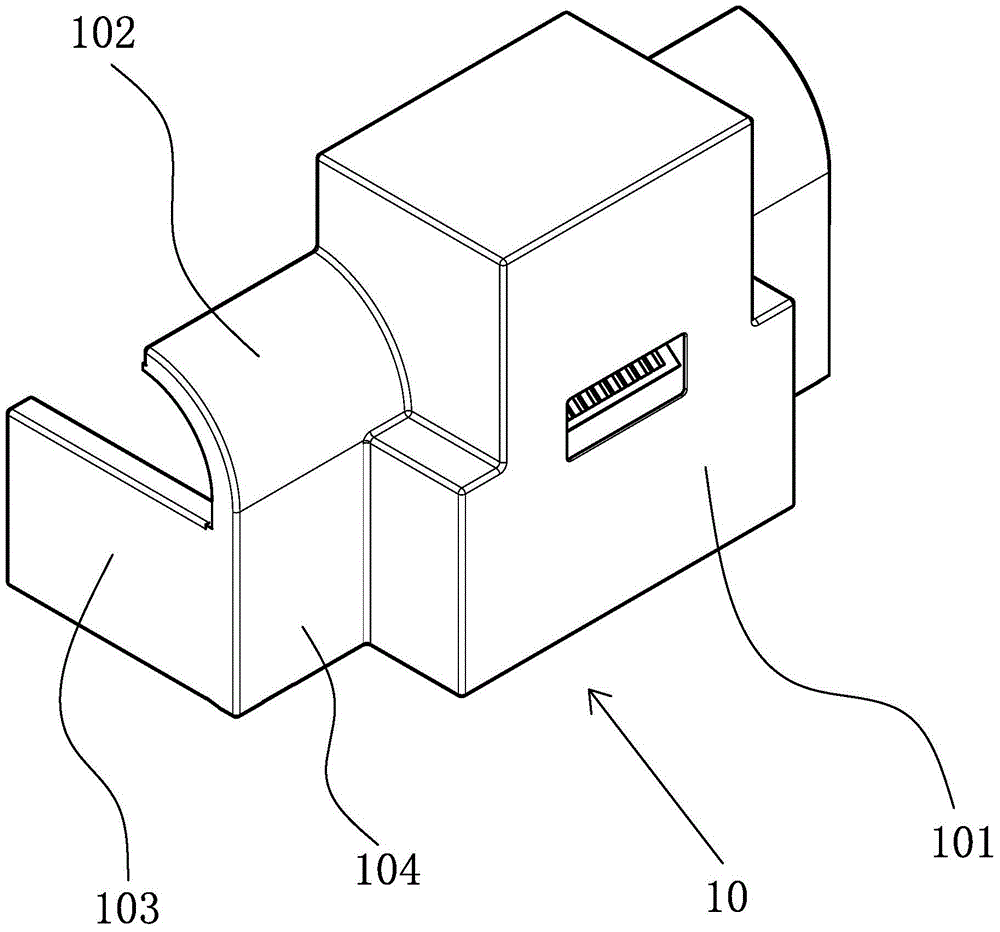

Top surrounding type extractor hood

A range hood, top-side technology, which is applied in the field of surrounding top-side range hoods, can solve the problems of only reaching 95%, general range hood effect, and inability to absorb range hood, so as to improve the range hood rate, The effect of high oil fume suction efficiency and comfortable cooking environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

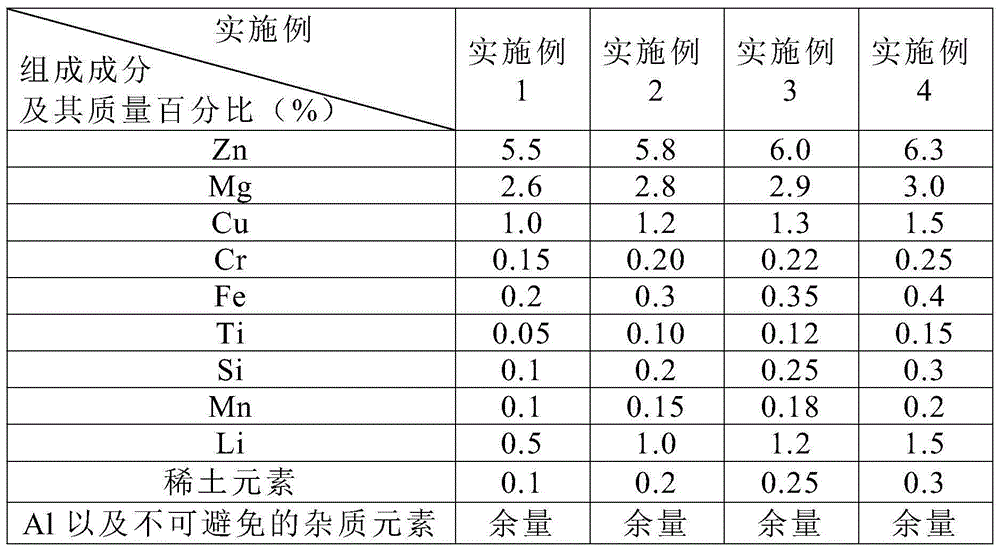

[0036] Take the aluminum alloy material according to the composition and mass percentage in Example 1 in Table 1 to make the oil fume separation plate blank. After heat treatment, the blank is first heated to 450°C, kept for 150 minutes, and then immersed in liquid nitrogen for 50 minutes for cryogenic treatment. After the cryogenic treatment, aging treatment was carried out at a temperature of 120° C. for 10 h. After conventional processing, the final oil fume separation board is made.

Embodiment 2

[0038] Take the aluminum alloy material according to the composition and mass percentage in Example 2 in Table 1 to make the oil fume separation plate blank. After heat treatment, the blank is first heated to 460°C, kept for 130 minutes, and then immersed in liquid nitrogen for 40 minutes for cryogenic treatment. After the cryogenic treatment, aging treatment was carried out at a temperature of 130° C. for 8 hours. After conventional processing, the final oil fume separation board is made.

Embodiment 3

[0040] Take the aluminum alloy material according to the composition and its mass percentage in Example 3 in Table 1 to make the oil fume separation plate blank. After heat treatment, the blank is first heated to 480°C, kept for 120 minutes, and then immersed in liquid nitrogen for 30 minutes for cryogenic treatment. After the cryogenic treatment, aging treatment was carried out at a temperature of 140° C. for 5 hours. After conventional processing, the final oil fume separation board is made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com