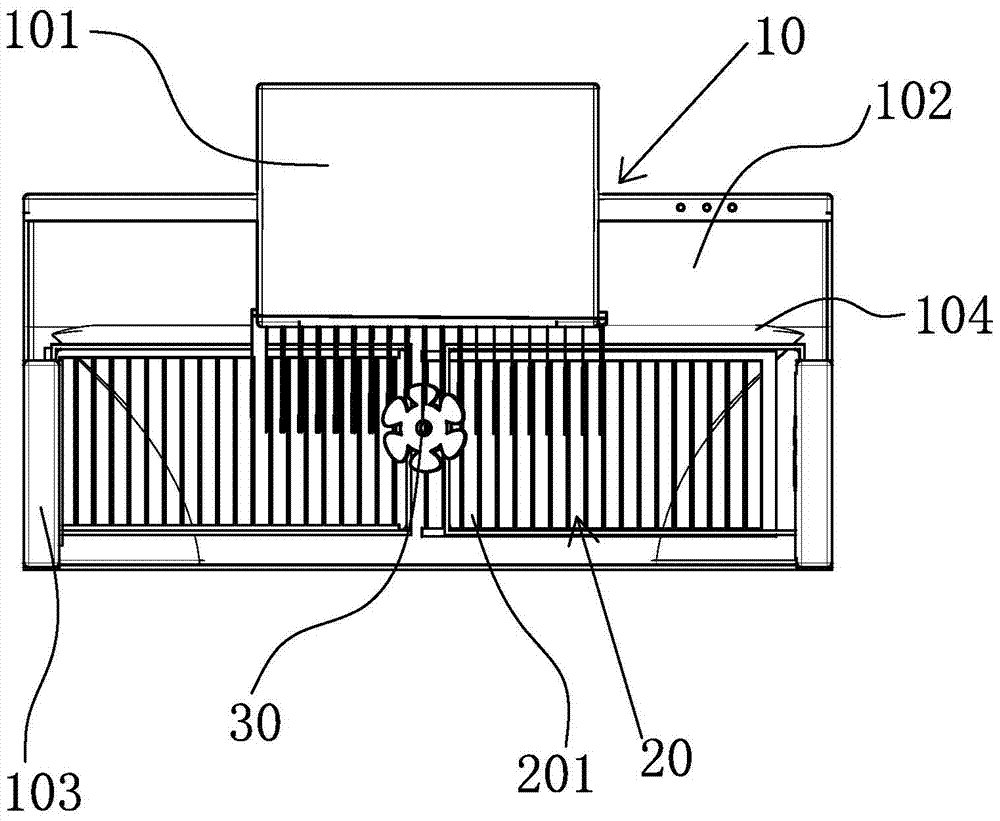

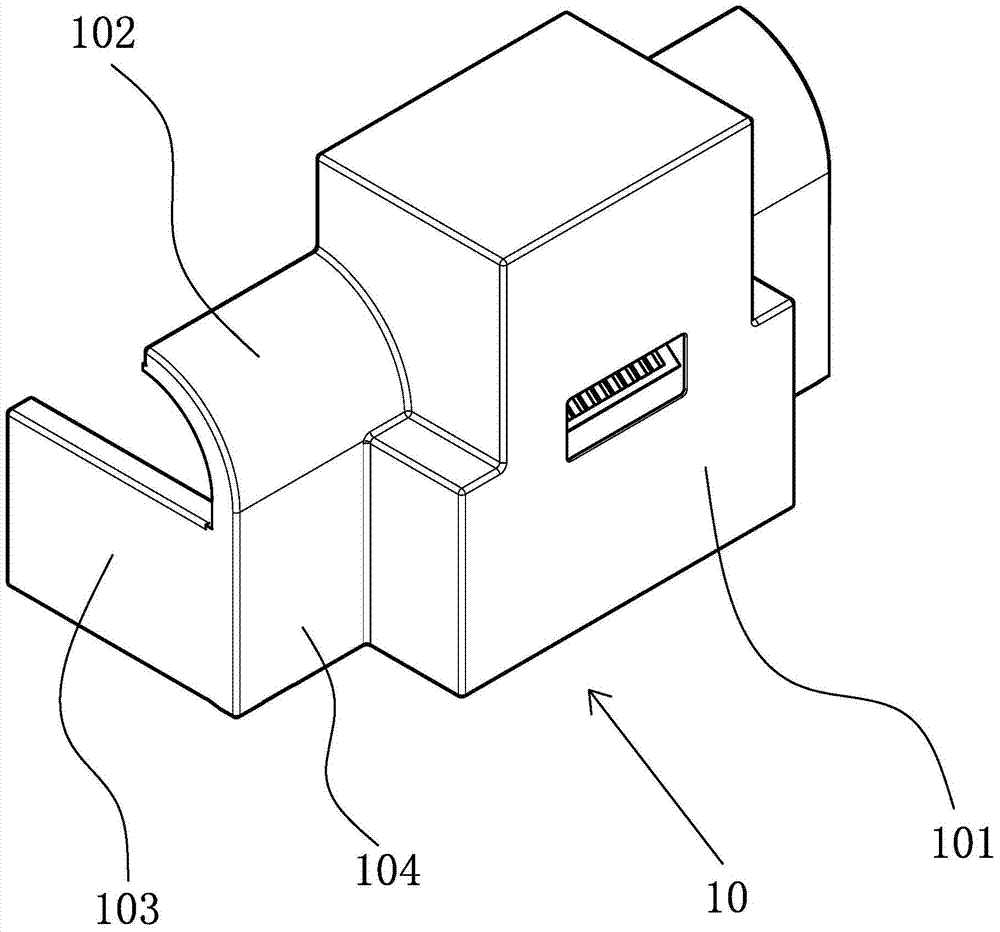

A low-noise surround top-side range hood

A range hood, top-side type technology, applied in the field of range hoods, can solve the problems of poor range hood, high noise, only reaching 95%, etc., so as to improve the range hood, improve corrosion resistance, and improve electrode effect of electric potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

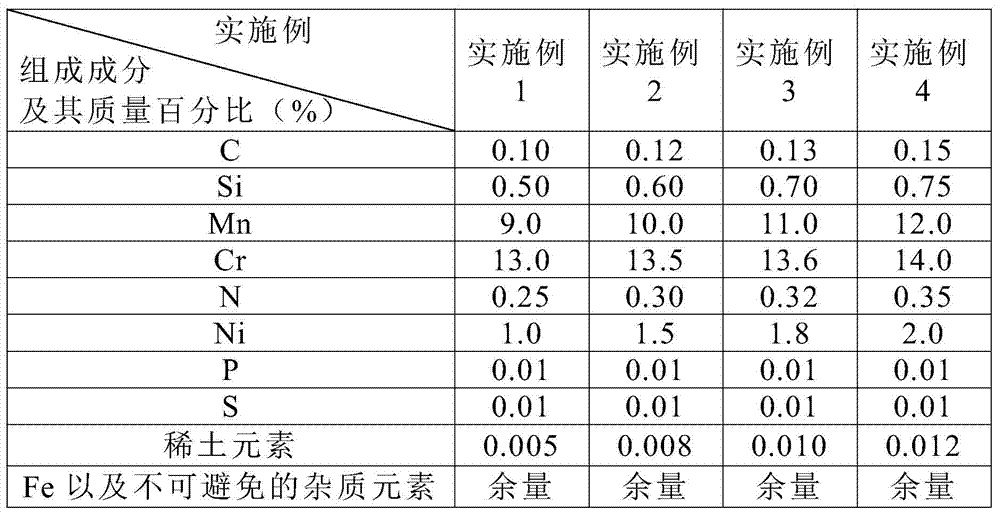

Examples

Embodiment 5

[0049] Embodiment 5: Select the housing made of stainless steel in any embodiment of the present invention, and coat the surface of the housing with a fireproof and sound-absorbing coating with a thickness of 0.5 mm. The fire-proof and sound-absorbing coating is prepared from the fire-proof and sound-absorbing coating according to the prior art. The fireproof and sound-absorbing coating is composed of 100 parts of polymer emulsion, 30 parts of expanded perlite filler and 3 parts of additives. The content of dispersant, plasticizer, wetting agent, thickener and film-forming aid in the auxiliary agent is 10% of the total amount of auxiliary agent, the content of defoamer is 5% of the total amount of auxiliary agent, and the balance All are pigments.

Embodiment 6

[0050] Embodiment 6: Select the housing made of stainless steel in any embodiment of the present invention, and coat the surface of the housing with a fireproof and sound-absorbing coating with a thickness of 1 mm. The fire-proof and sound-absorbing coating is prepared from the fire-proof and sound-absorbing coating according to the prior art. The fireproof and sound-absorbing coating is composed of 100 parts of polymer emulsion, 35 parts of expanded perlite filler and 5 parts of additives. Among the auxiliary agents, the dispersant is 10% of the total amount of auxiliary agents, the plasticizer is 12% of the total amount of auxiliary agents, the wetting agent is 13% of the total amount of auxiliary agents, the thickener is 12% of the total amount of auxiliary agents, The film-forming auxiliary agent is 15% of the total amount of the auxiliary agent, the content of the defoamer is 3% of the total amount of the auxiliary agent, and the balance is pigment.

Embodiment 7

[0051] Embodiment 7: Select the housing made of stainless steel in any embodiment of the present invention, and coat the surface of the housing with a fire-proof and sound-absorbing coating with a thickness of 1 mm. The fire-proof and sound-absorbing coating is prepared from the fire-proof and sound-absorbing coating according to the prior art. The fireproof and sound-absorbing coating is composed of 100 parts of polymer emulsion, 40 parts of expanded perlite filler and 8 parts of additives. Among the auxiliary agents, the dispersant is 12% of the total amount of auxiliary agents, the plasticizer is 15% of the total amount of auxiliary agents, the wetting agent is 15% of the total amount of auxiliary agents, the thickener is 10% of the total amount of auxiliary agents, The film-forming auxiliary agent is 10% of the total amount of the auxiliary agent, the content of the defoamer is 4% of the total amount of the auxiliary agent, and the balance is pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com