Water cooler

A water cooler and liquid level sensor technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as difficult fluid conditions, unstable heat exchange performance of equipment, equipment damage, etc., to achieve Maintain a safe and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

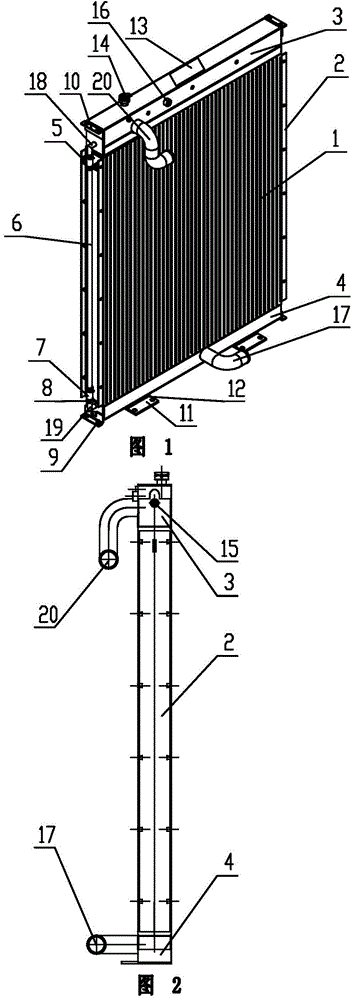

[0013] The present invention will be further described below in conjunction with specific drawings.

[0014] Such as Figure 1 ~ Figure 2 As shown: the water cooler includes a core 1, a bracket assembly 2, an upper head 3, a lower head 4, lifting lugs 5, a connecting pipe 6, a rubber pipe 7, a clamp 8, a second bracket 9, a first Bracket 10, support plate 11, aluminum bar 12, sign 13, expansion port cover 14, liquid level sensor 15, observation window 16, water inlet pipe 17, upper bend pipe 18, lower bend pipe 19, water outlet pipe 20, etc.

[0015] The present invention comprises a core 1, the left and right sides of the core 1 are provided with bracket assemblies 2, and the upper and lower sides of the core 1 are respectively provided with an upper sealing head 3 and a lower sealing head 4; the upper sealing head 3 is provided with a liquid level sensor 15 and Observation window 16, the top of the upper head 3 is provided with a sign 13 and an expansion port, the expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com