Device for measuring pouring amount of motor propellant

A propellant and engine technology, which is applied in the field of solid rocket motors, can solve problems such as the inability to accurately control the pouring amount of solid propellants, and solve the problem of storage management of unqualified dangerous goods, eliminate unqualified products, and solve the problem of storage of unqualified products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

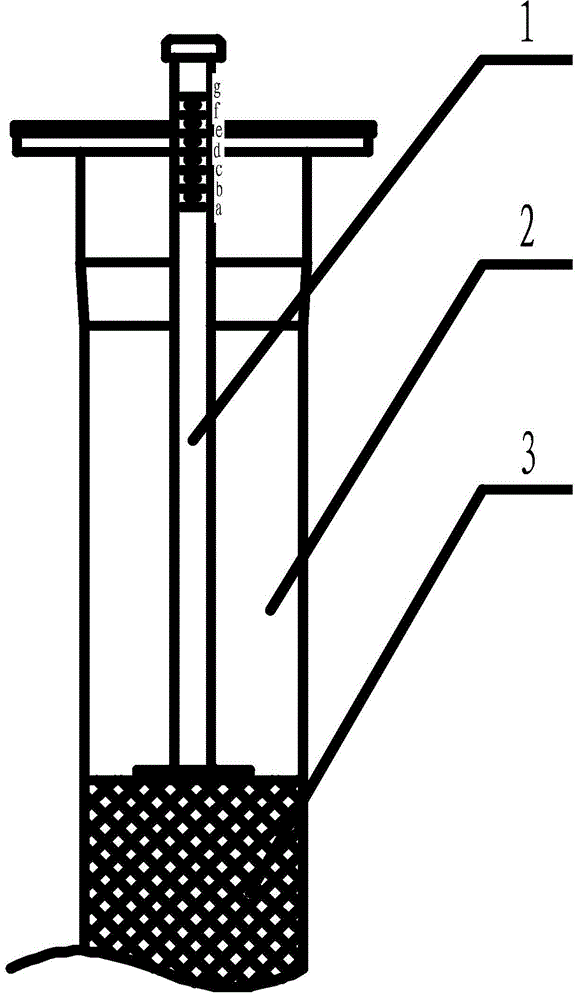

[0016] This embodiment is a device for measuring the pouring amount of engine propellant.

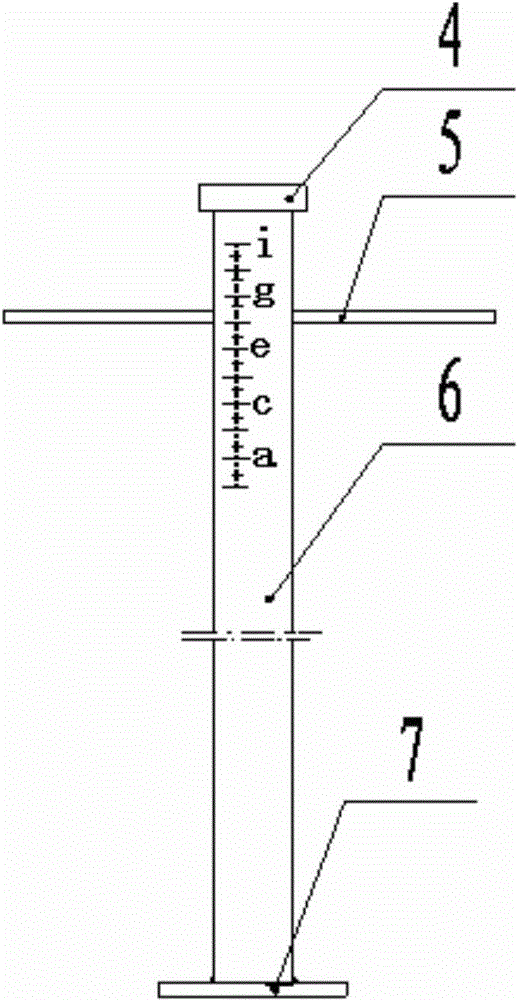

[0017] Such as figure 2 As shown, the engine pouring propellant measuring device 1 includes a nut 4 , a positioning plate 5 , a measuring rod 6 and a measuring disc 7 . There are scale lines on the surface of the shaft at the top of the measuring rod 6, and every small grid scale line is spaced at 1mm, 60 small grids in total. Every 10 small grids is a large grid, marked with English letters a~j respectively. The positioning plate 5 is sleeved on the upper part of the measuring rod, and is slidably fitted with the measuring rod. The nut 4 is installed on the upper end surface of the measuring rod 6 , and the measuring disk 7 is welded on the lower end surface of the measuring rod 6 .

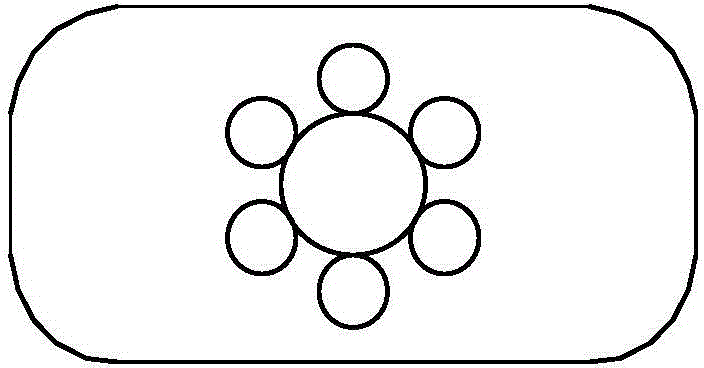

[0018] The positioning plate 5 is a square thin aluminum plate, and there is a through hole for installing the measuring rod 6 at the geometric center. The through hole is surrounded by 6 observation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com