A high-temperature gas atomization rapid cooling system and method

A high-temperature gas, rapid cooling technology, applied in the direction of water shower cooler, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of long cooling process or equipment, difficult rapid acute cooling, and dioxin pollution, etc. Ensure that process conditions are in place and equipment safety, solve technical problems in environmental protection, and shorten the effect of cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: Prevention and treatment system of dioxin pollution

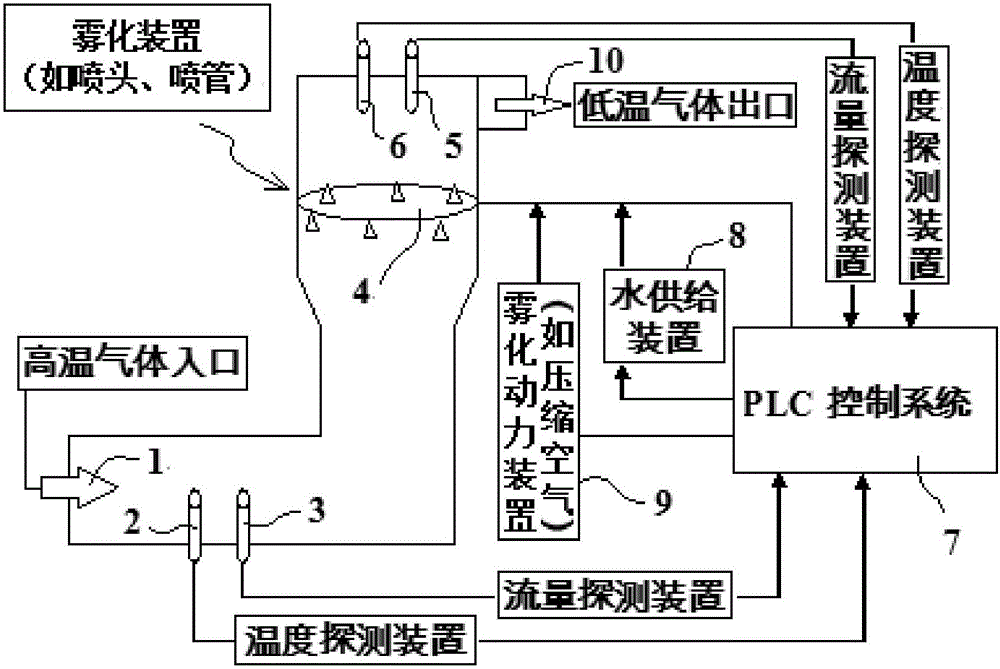

[0040] As shown in the figure, the high-temperature gas atomization rapid cooling system of the present invention includes: high-temperature gas inlet 1, temperature probe 2, gas flow probe 3, atomization nozzle 4, temperature probe 5, gas flow probe 6, PLC control system 7, Cooling water supply device 8 , atomization power device (such as compressed air) 9 , low-temperature gas outlet 10 .

[0041] The high-temperature gas generated after the high-temperature incineration of plastic materials passes through the high-temperature gas inlet 1 (for example, the temperature is 800°C), and through the subsequent fan suction (such as the fan behind the low-temperature gas outlet 10), the gas is guided to flow to the cooling tower; the high-temperature gas passes through the temperature probe 2 and the gas flow probe 3, respectively measure the temperature (such as temperature 800°C) and flow (Q); quickly tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com