A safety protection device for downhole tool ultra-high pressure hydraulic test

A technology of safety protection device and hydraulic test, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of hidden safety hazards, long time consumption, inconvenient information exchange, etc., to reduce costs and occupation. Space, the effect of reducing additional labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing:

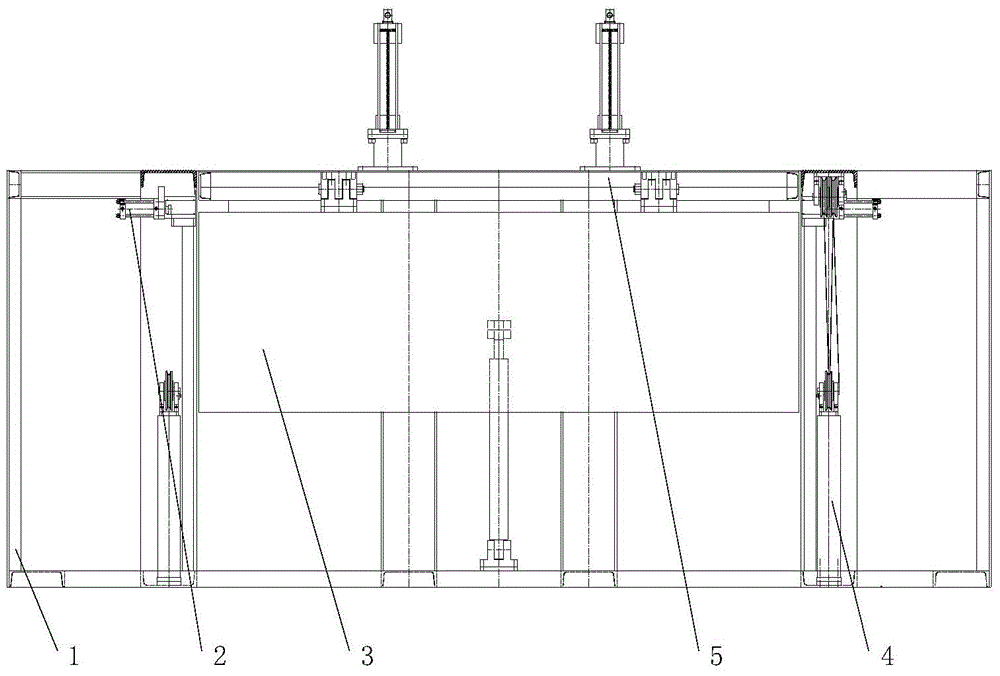

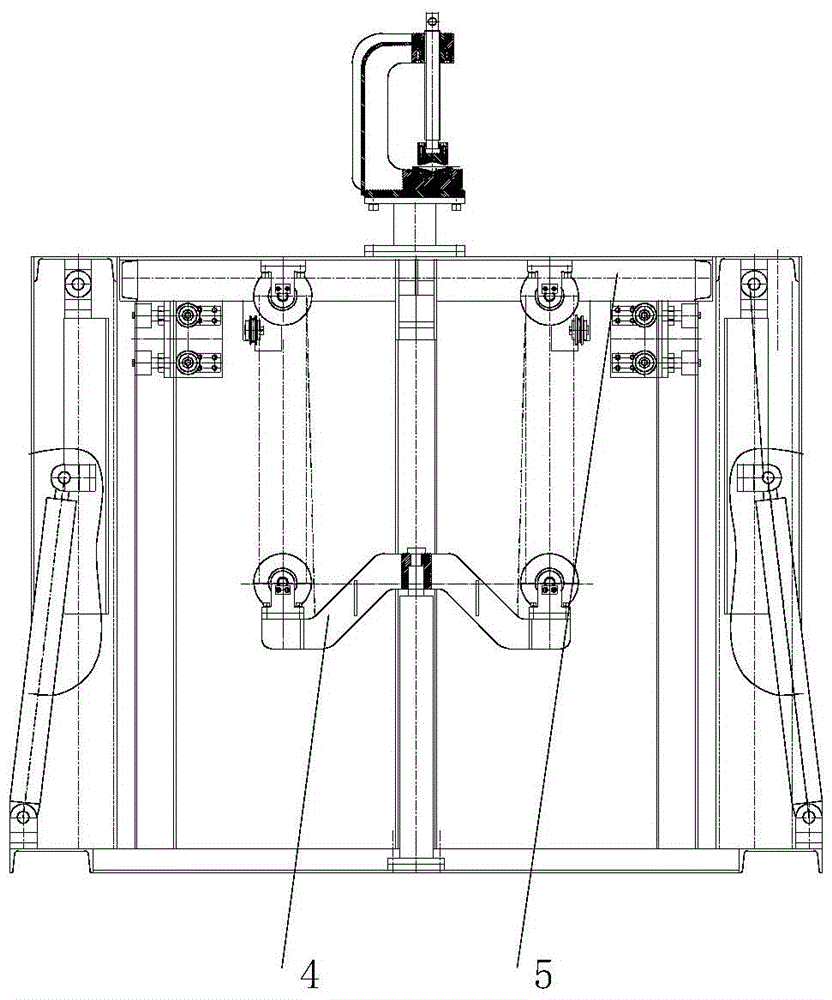

[0049] Depend on Figure 1 to Figure 27 As shown, a safety protection device for ultra-high pressure hydraulic testing of downhole tools includes a frame box 1, the front and rear sides of the frame box 1 are fixed with protective cover mechanisms 3, and the left and right sides of the frame box 1 are fixed There is a platform lifting mechanism 4, the upper part of the platform lifting mechanism 4 is connected with a lifting platform 5, and the left and right sides of the upper part of the frame box 1 are fixed with a safety sliding support mechanism 2 through columns, and the safety sliding support mechanism 2 is located on both sides of the lifting platform 5 side. The protective device is described in detail below.

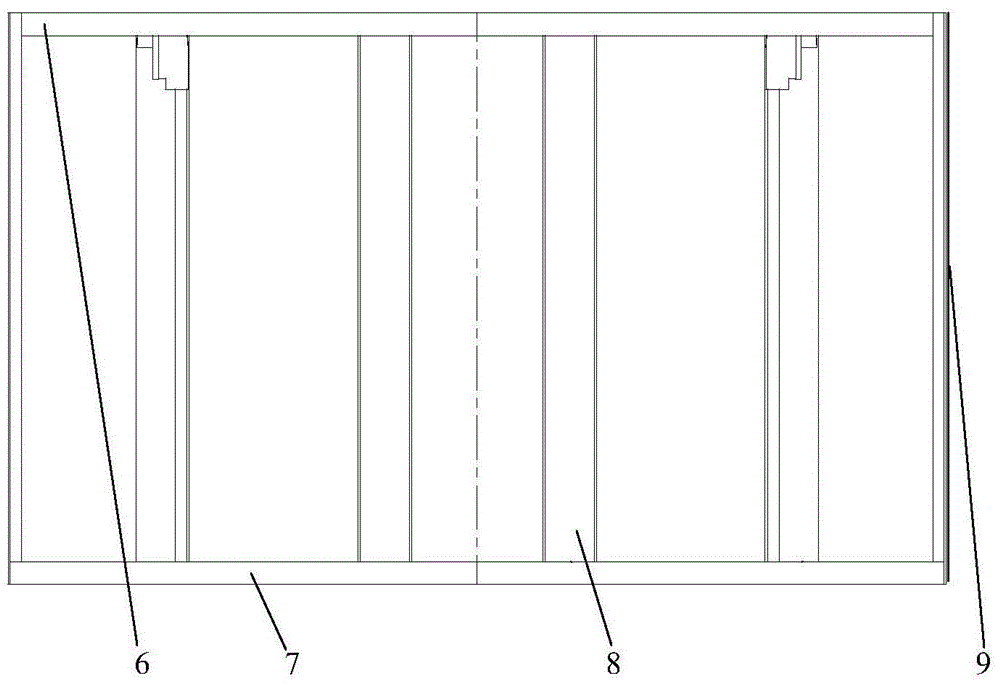

[0050] The main body of the frame box 1 adopts a channel steel welded structure, mainly including a rectangular top frame 6 and a bottom frame 7, and fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com