Tree pruning elevator

A technology of tree pruning and elevators, applied in the direction of lifting frames, lifting devices, etc., can solve problems such as time-consuming, labor-intensive, and potential safety hazards, and achieve the effects of improving work efficiency, safe and reliable use, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

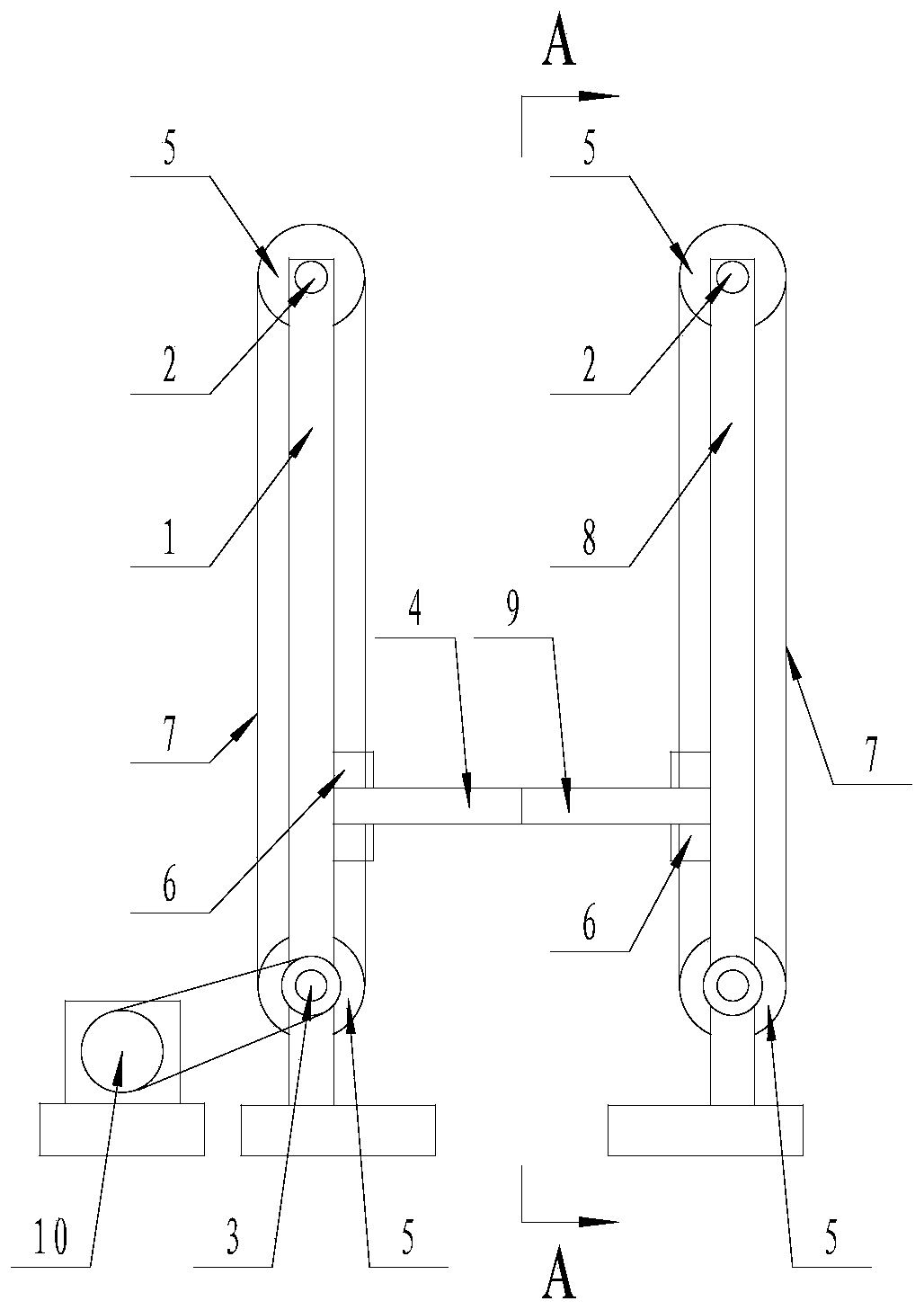

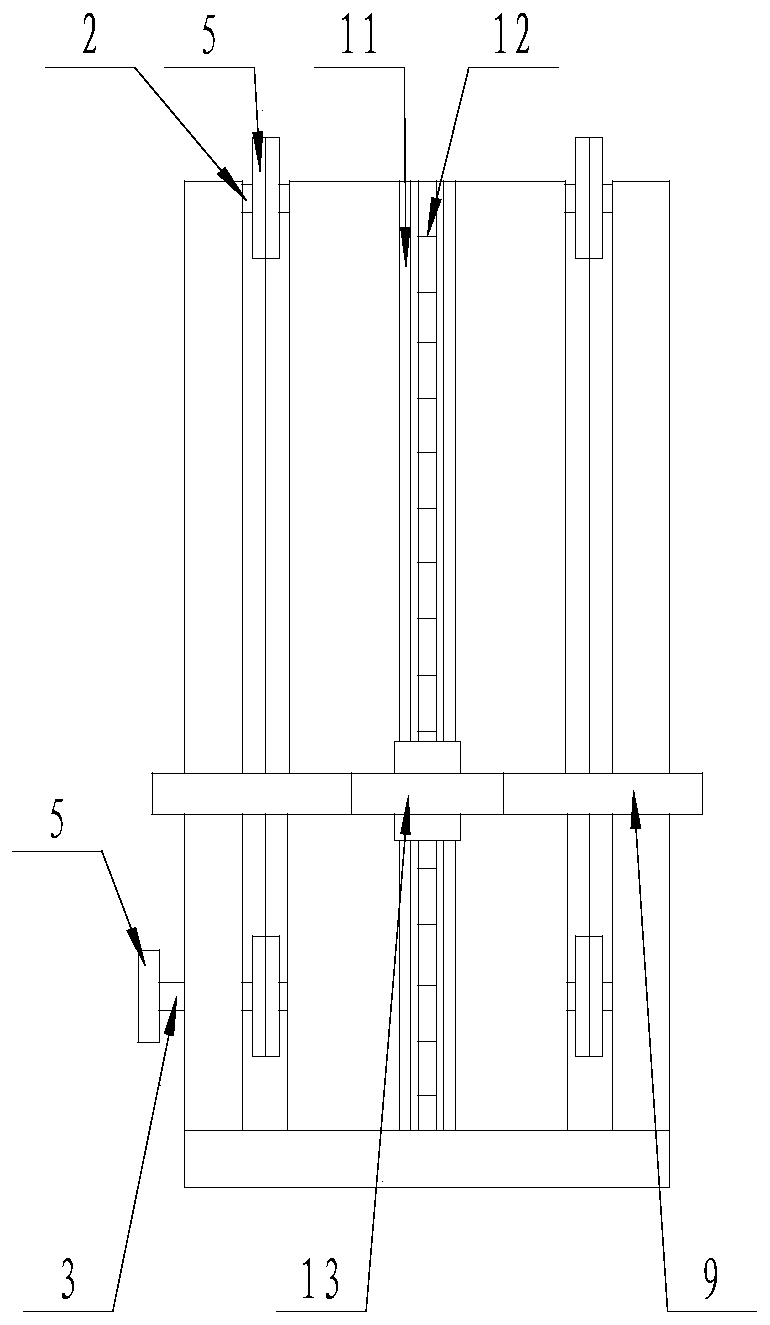

[0021] Such as figure 1 , figure 2 Shown, a kind of lift special for tree pruning, comprises the first lifting frame 1, the second lifting frame 8, the first lifting frame 1 and the second lifting frame 8 are respectively provided with lifting transmission mechanism, the first lifting frame 1 and the second lifting frame The lifting transmission mechanisms of the two lifting frames 8 are respectively connected with the first lifting platform 4 and the second lifting platform 9, and the first lifting platform 4 and the second lifting platform 9 are detachably connected. The first lifting frame 1 and the second lifting frame 8 can be used alone or in combination. It is flexible and convenient to use alone, and is suitable for single-person work. The combined use has a wide range of work, is safer and more reliable, and is suitable for multi-person work.

Embodiment 2

[0023] The lifting transmission mechanism includes a motor 10, a transmission shaft 3 and a driven shaft 2, and the transmission shaft 3 and the driven shaft 2 are respectively fixed with at least one group of sprockets 5, and the chain wheels 5 of the transmission shaft 3 and the driven shaft 2 The sprocket 5 is arranged vertically correspondingly and is connected by a chain 7 , and one end of the transmission rotating shaft 3 is also provided with a sprocket 5 connected to the motor 10 by the chain 7 . The structure of the lifting transmission mechanism is not limited to the above-mentioned structure, and other structures similar to the present application can also be used, such as gear transmission, hydraulic lifting and other structures.

[0024] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

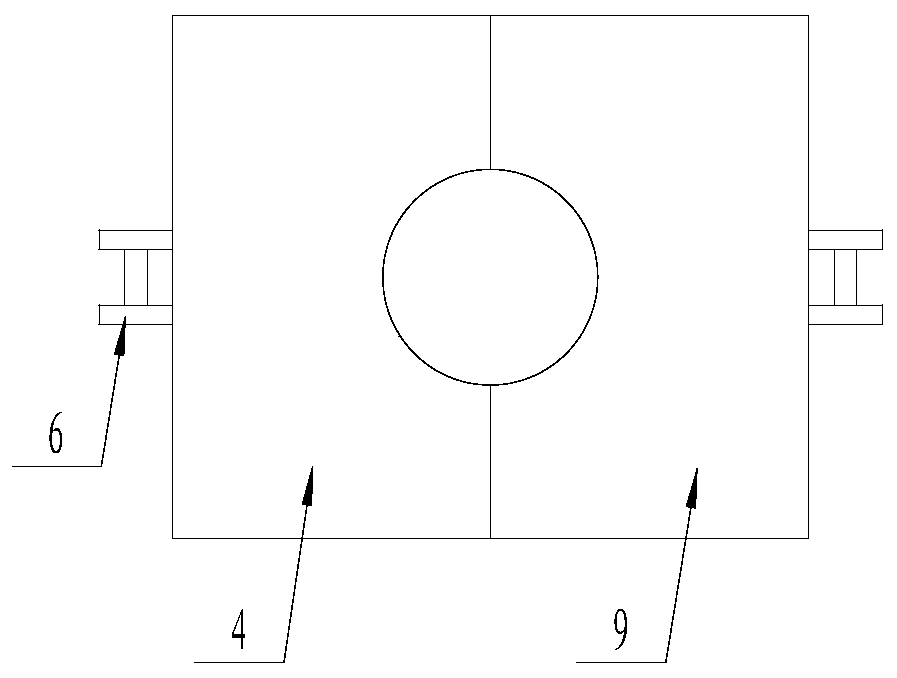

[0026] Such as Figure 1-4 As shown, an anti-falling device is also provided between the lifting platform and the lifting frame. The anti-falling device includes a hook 12, a slide rail 11 and a hanging seat 6, and the hooks 12 are vertically arranged and fixed on the first lifting frame 1 and the second lifting frame 8. Inside, the slide rail 11 is arranged in parallel on both sides of the hook 12, one end of the hanging base 6 is movably connected with the slide rail 11, and the other end is fixedly connected with the first lifting platform 4 or the second lifting platform 9, and the front connecting plate of the hanging base 6 is provided with The arc-shaped hole track 14 is high and low, and a load-bearing pin 15 that can slide along the arc-shaped hole track 14 is arranged inside the arc-shaped hole track 14 .

[0027] Such as Figure 4 As shown, during the slow lifting process of the lifting platform, after the load-bearing pin 15 touches the hook 12, it slowly rises al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com