Synchronous lifting double insulator string

A technology of insulator strings and insulator groups, which is applied in the direction of suspension/strain insulators, can solve the problems of damage, peeling, cracks and other problems on the surface of insulator ceramics, and achieve the effect of increasing the force-bearing area, enhancing the tensile capacity, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

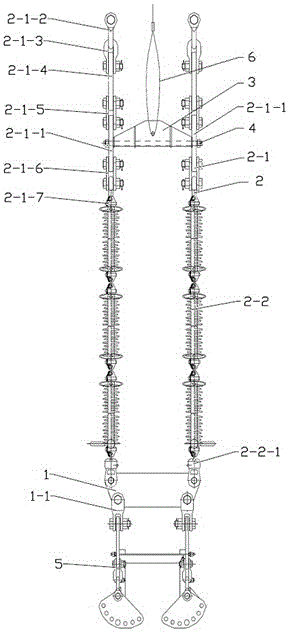

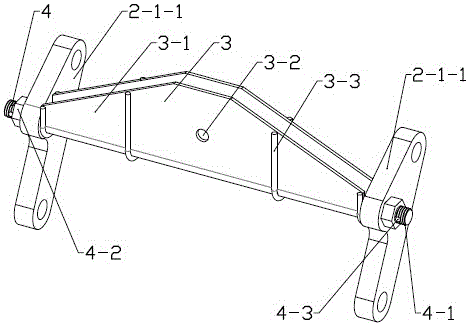

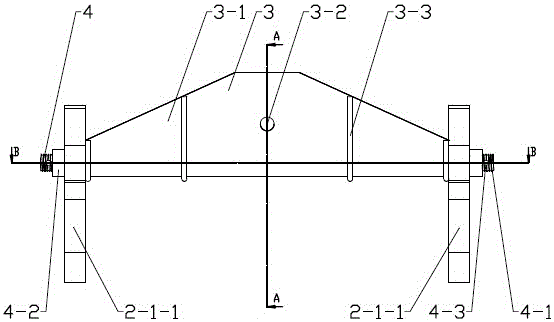

[0023] The synchronous lifting type double insulator string of the present invention comprises two insulator strings 2 arranged side by side in parallel, the lower ends of which are connected together by connecting plates 1, and the insulator string 2 includes suspension fittings strings 2-1 sequentially connected from top to bottom And insulator group 2-2. see details figure 1 shown.

[0024] The suspension fittings string 2-1 of the insulator string 2 includes hanging point fittings 2-1-2, U-shaped hanging rings 2-1-3, DB-type adjusting plates 2-1-4, P-type first One parallel hanging plate 2-1-5, traction plate 2-1-1, P type second parallel hanging plate 2-1-6, Q type ball head hanging ring 2-1-7, for hanging fittings string 2-1 In the suspension insulator group 2-2. The insulator group 2-2 includes 2 to 4 insulators connected in sequence, and the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com