Line outgoing method of composite insulator

A technology of synthesizing insulators and outgoing bridges, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inconvenient use on site, increase the cross-section, and increase the labor intensity of operators, so as to reduce labor intensity, reduce weight, improve work efficiency and The effect of work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

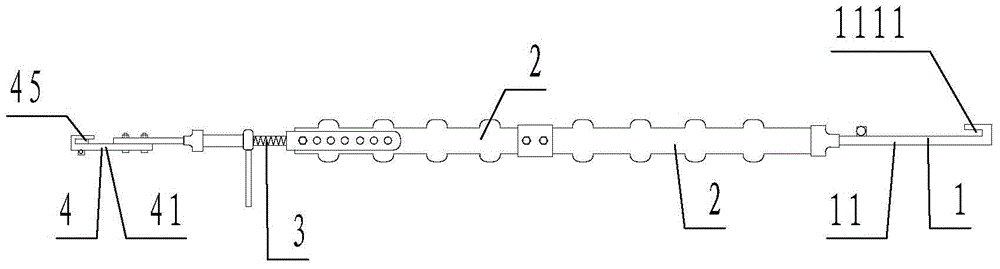

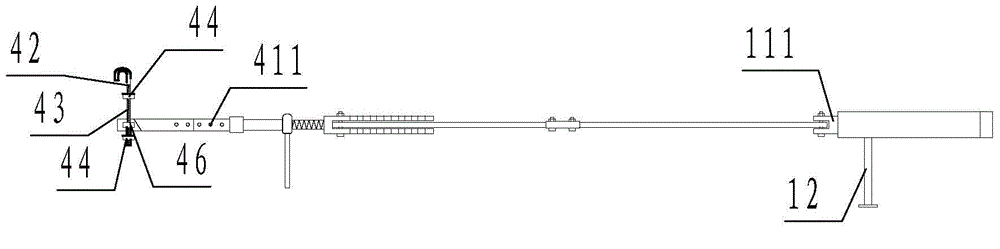

[0027] A composite insulator outlet bridge, including a wire side connecting plate hook 1, an insulating bridge plate 2, a tensioning device 3, and a cross arm side connecting plate hook 4, the conducting wire side connecting plate is square, and the conducting wire side connecting plate hook It includes a sheet-shaped connecting plate 11. One end of the connecting plate is provided with a connecting piece 111 that matches the insulating bridge plate. The connecting plate and the connecting piece are vertically intersected. The connecting piece is movably connected to the insulating bridge plate. The other end is provided with a hook groove 1111 that can be hooked into the square connecting plate, and a supporting leg 12 perpendicular to the connecting piece is also provided on the connecting piece, and the supporting leg is supported at the double bowl head.

[0028] The insulating bridge plate is formed by connecting several sections, and a detachable movable connection is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com