Suction liquid feeding electronic cigarette

An electronic cigarette and liquid supply technology, which is applied in the field of electronic cigarettes, can solve the problem of volume reduction of oil storage tanks and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

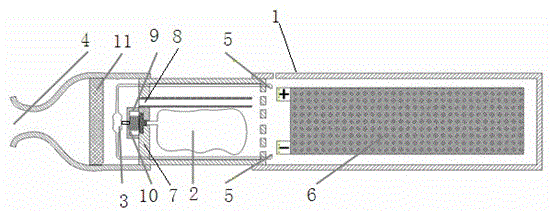

[0011] The electronic cigarette for liquid supply by suction in the figure includes a housing 1, an oil storage tank 2, a heating element 3, a cigarette holder 4, a heating element wire 5, and a battery 6, and is characterized in that a partition 7 is arranged at the front end of the cigarette holder, and There is an air hole 8 on the top, the air hole is connected to the atmosphere through the casing, one end of the air hole is close to the cigarette holder and the other end is connected to the atmosphere through the casing; the other is an oil hole 10, and the end of the oil hole near the cigarette holder is close to the other end of the heating element through a one-way valve 9 Connect with oil storage tank 2. The oil storage tank is a container made of non-elastic membrane material. A filter membrane 11 is arranged in the cigarette holder. An air inlet or an air inlet slit (not shown in the figure) is provided on the housing. A pneumatic micro switch (not shown in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com