Production method of intelligent superfine aluminum powder capable of realizing multiple classification

A production method and multi-classification technology, applied in centrifuges and other directions, can solve problems such as wide distribution of particle size range, and achieve the effects of solving wide distribution of particle size range, saving calculation time, and improving calculation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

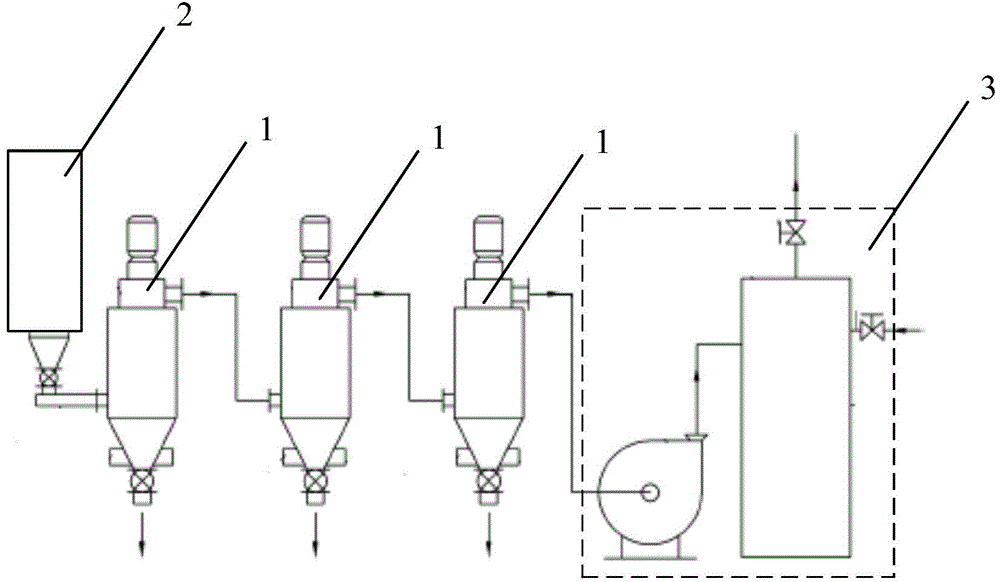

[0030] See figure 1 As shown, a production method of intelligent ultrafine aluminum powder includes: an ultrafine aluminum powder classification system; the ultrafine aluminum powder classification system includes: several levels of aluminum powder classification devices 1, and the previous level of aluminum powder classification devices The powder outlet of the aluminum powder grading device is connected to the powder inlet of the last-level aluminum powder grading device; wherein, the powder inlet of the first-level aluminum powder grading device is connected to the powder outlet of the aluminum powder powder making device 2; the final aluminum powder grading device The powder outlet is connected to the air inlet of the cyclone dust collector 3; the structure of each aluminum powder classification device 1 is the same, and it includes: a centrifugal classifier, which is suitable for collecting the buffer of the coarse powder separated by the aluminum powder classification dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com