Method for preparing ternary precursor and reaction device

A reaction device and precursor technology, applied in chemical instruments and methods, electrical components, nickel compounds, etc., can solve the problem of wide particle size distribution of ternary precursors, and achieve the effect of reducing agglomeration, increasing energy density, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

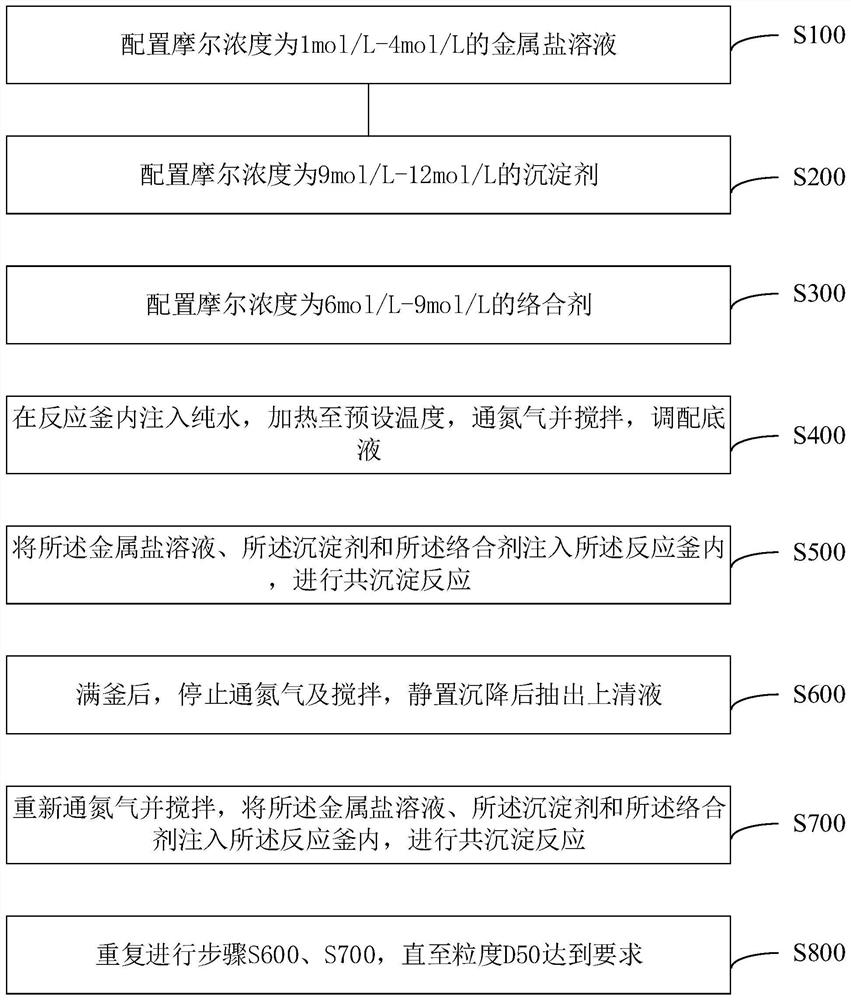

[0060] The beneficial effects of the method and reaction device for preparing a ternary precursor provided by the present invention are: the molar concentration of the metal salt solution is 1mol / L-4mol / L, the molar concentration of the precipitating agent is 9mol / L-12mol / L, complexation The molar concentration of the agent is 6mol / L-9mol / L, and the batch method is used to repeat the co-precipitation reaction many times, effectively controlling the particle size and particle size distribution, and preparing a ternary precursor with a narrow particle size distribution, which solves the problem of existing ternary precursors. The technical problem of wide particle size distribution, the ternary precursor with narrow particle size distribution can effectively reduce the agglomeration of particles in the high-temperature lithium-mixed sintering section, effectively use the space between particles to increase the energy density of the material, and obtain a power battery positive ele...

Embodiment 2

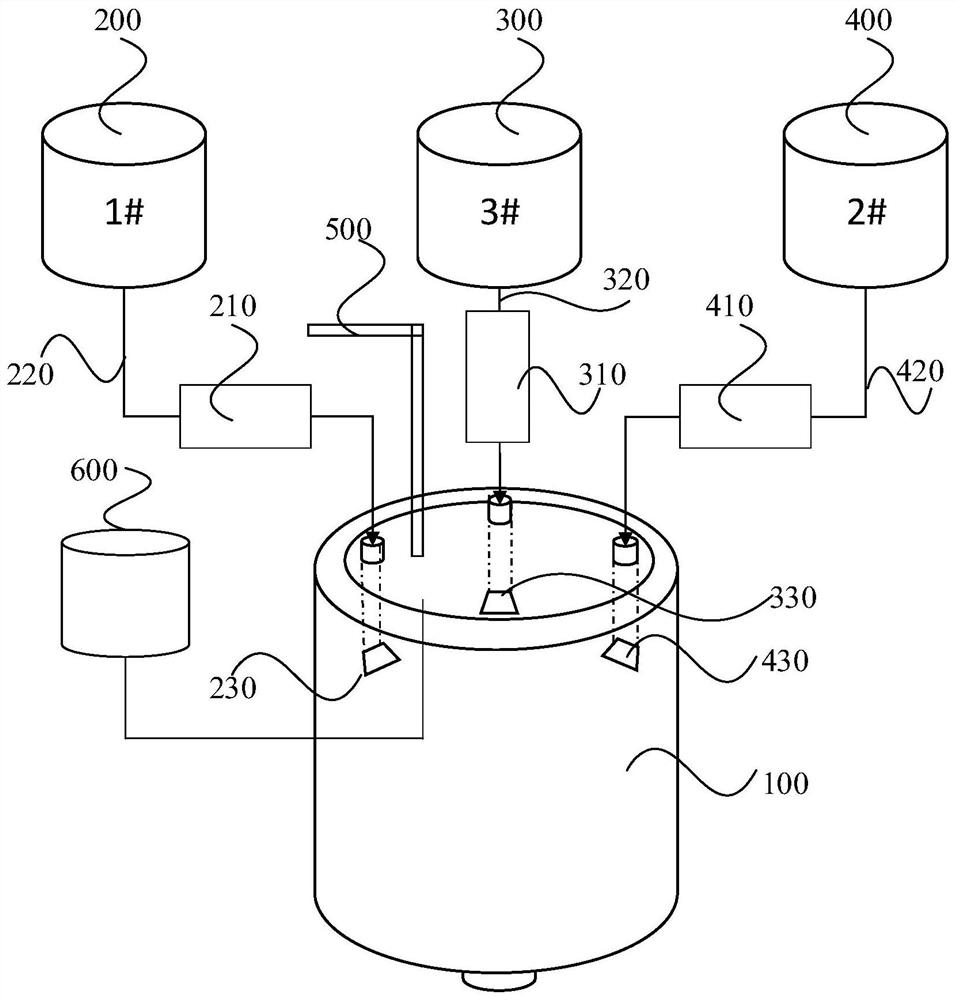

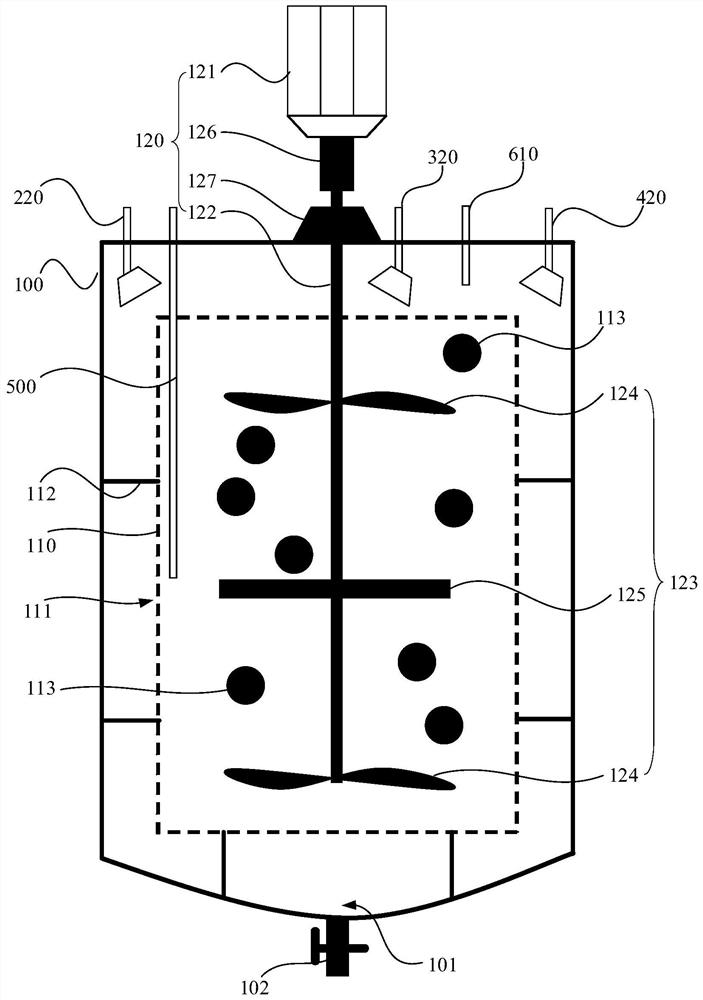

[0078] Please refer to figure 2 , the present invention also provides a reaction device using any one of the methods for preparing a ternary precursor, including a reactor 100, a first container 200, a second container 300, a third container 400, a pure water pipeline 500 and The nitrogen tank 600, the reactor 100 is equipped with a heater for controlling the internal temperature of the reactor 100, the first container 200 is used to hold the metal salt solution, the second container 300 is used to hold the precipitant, and the third container 400 is used to hold the complexing agent. agent, the first container 200, the second container 300, the third container 400, the pure water pipeline 500 and the nitrogen tank 600 respectively supply the metal salt solution, the precipitating agent, the complexing agent, pure water and nitrogen to the reactor 100.

[0079] This reaction device applies any one of the preparation methods of Embodiment 1, the molar concentration of the meta...

Embodiment 3

[0113] In this example, a specific method in Example 1 is used to prepare a ternary precursor with a D50 of 10.5 μm and a narrow particle size distribution (Spanx co y mn (1-x-y) (OH) 2 , wherein x=0.8~0.9, y=0~0.2. The method comprises the steps of:

[0114] (1) configure metal salt solution, wherein Ni 2+ :Co 2+ :Mn 2+ =x:y:(1-x-y), wherein x=0.8~0.9, y=0~0.2;

[0115] (2) configuration molar concentration is the sodium hydroxide solution of 9mol / L-12mol / L;

[0116] (3) configuration molar concentration is the aqueous ammonia solution of 6mol / L-9mol / L;

[0117] (4) The first pipeline 220, the second pipeline 320 and the third pipeline 420 are respectively installed in the reaction kettle 100, and the outer ends are respectively connected with the first container 200 containing the metal salt solution, the second container 300 containing the sodium hydroxide solution and the ammonia containing solution. The third container 400 of the aqueous solution, and the flow is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com