Rotor locking sleeve structure for centrifuge

A technology of locking sleeves and centrifuges, applied in centrifuges and other directions, can solve the problems of difficulty in ensuring accuracy, difficult processing, and high processing accuracy requirements, and achieve the effects of easy disassembly, convenient processing, and guaranteed assembly concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

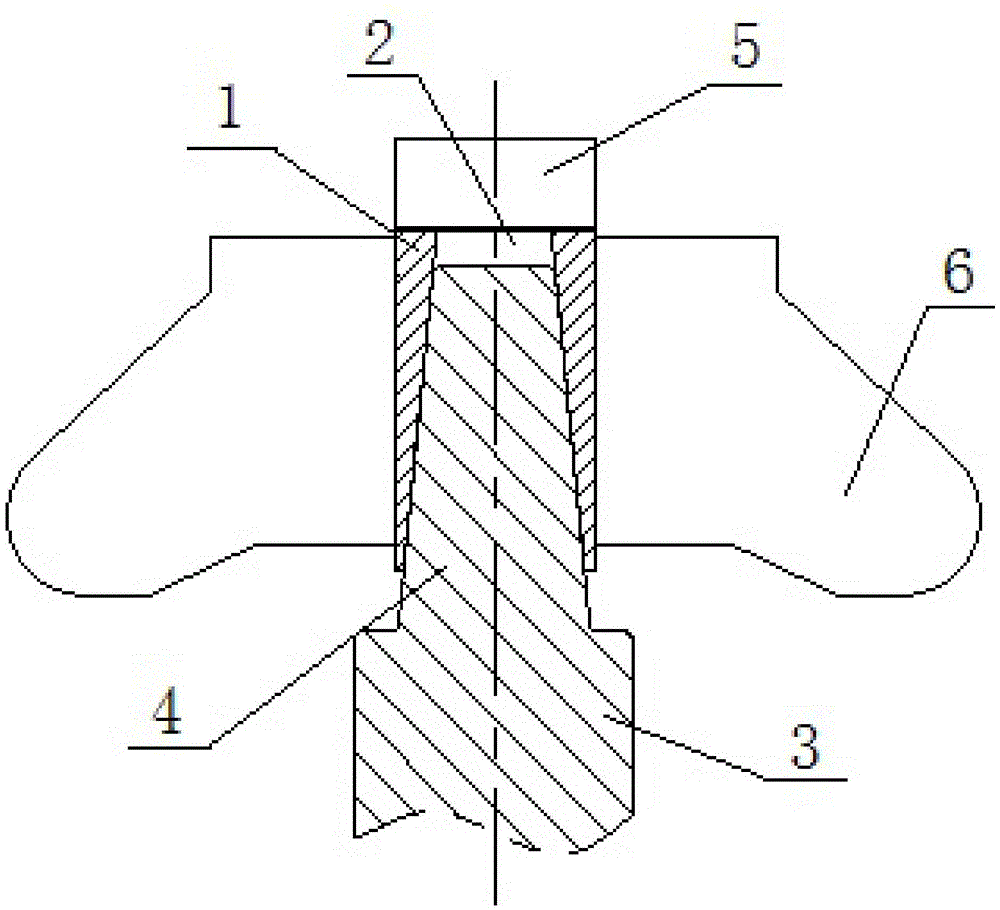

[0012] The rotor locking sleeve structure of the centrifuge of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, the rotor locking sleeve structure of the centrifuge of the present invention includes an elastic locking sleeve 1 with a clamping hole 2 in the shape of a truncated cone, and a locking screw or nut as a pressing device 5 . The end of motor main shaft 3 processes screw hole or screw rod, and pressing device 5, the assembly hole on the rotor 6 is processed into straight hole. The frustum-shaped clamping hole 2 of the locking sleeve 1 fits with the connecting end 4 of the frustum-shaped shape, and the outer circle of the locking sleeve 1 fits with the straight assembly hole of the rotor 6. 6 lock.

[0014] The assembly hole of the rotor of the rotor locking sleeve structure of the centrifuge of the present invention is made into a straight through hole, which is convenient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com