Liquid spraying device with cleaning component

A liquid spraying and component technology, which is used in spraying devices, spraying devices, and devices for coating liquids on surfaces, etc., can solve the problems of nozzle pollution and the difficulty of forming a uniform water curtain on the nozzle, and achieve the effect of ensuring the effect and keeping the nozzle clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

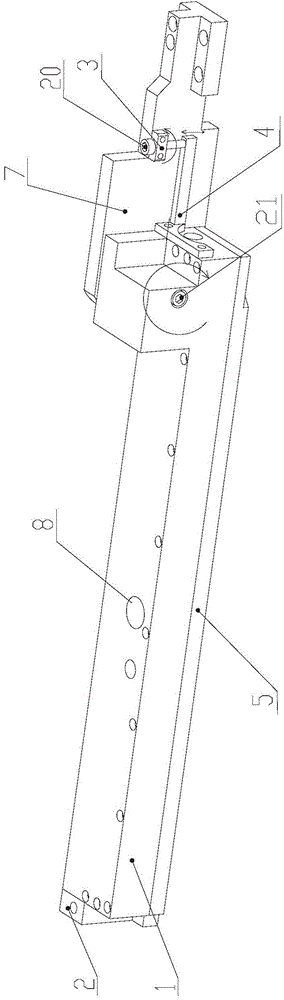

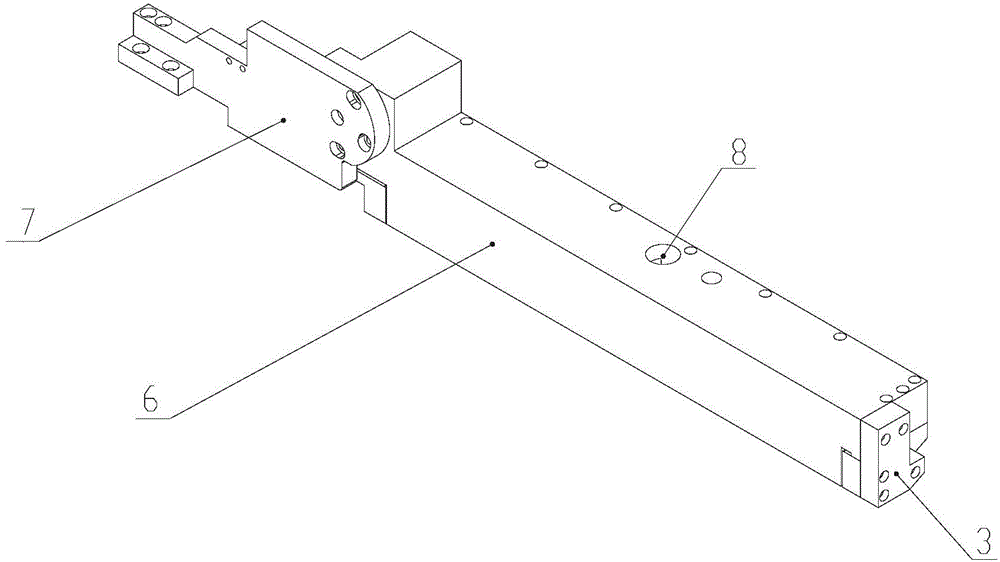

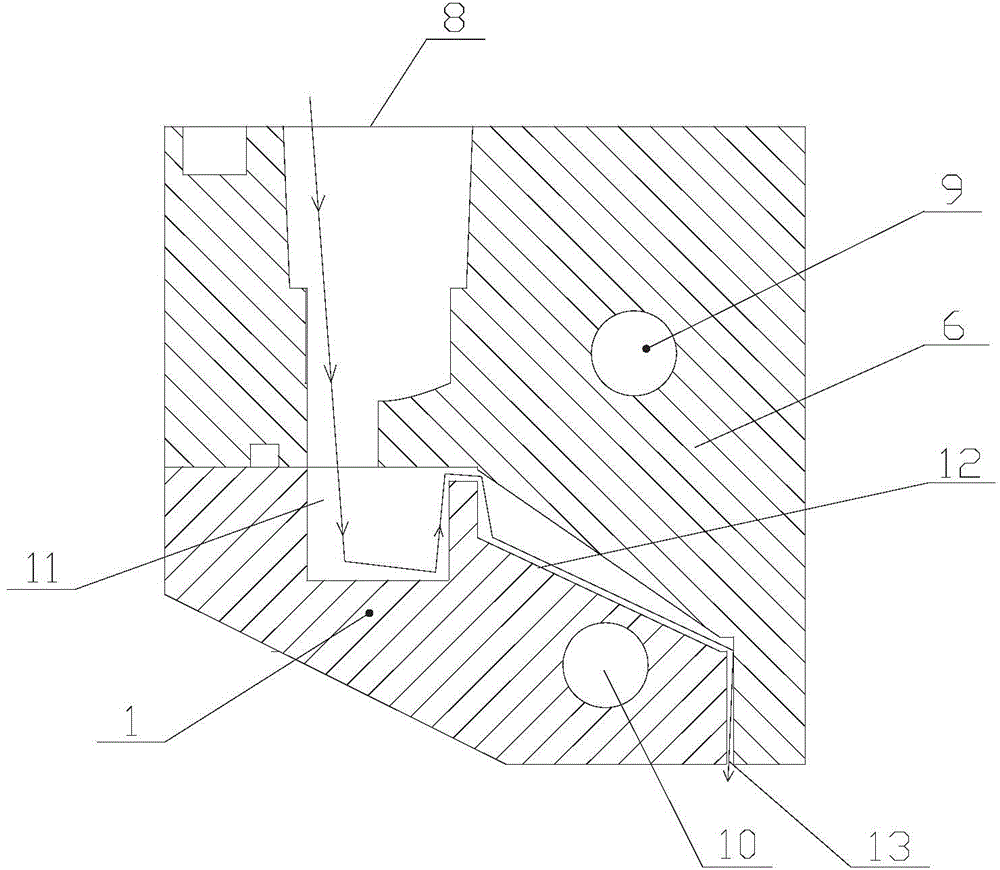

[0024] like Figure 1-5 Shown, the present invention comprises nozzle and cleaning part 5, and wherein nozzle comprises nozzle bottom part 1, nozzle loam cake 6 and heat preservation device, wherein the upper surface of nozzle bottom part 1 is provided with liquid uniform groove along length direction, and described nozzle The upper cover 6 is arranged on the top of the nozzle bottom part 1, and the side of the nozzle upper cover 6 corresponding to the liquid uniform distribution groove extends downwards, and a gap for forming a water curtain is left between the side wall of the nozzle bottom part 1. The gap 13, the nozzle upper cover 6 is provided with a liquid inlet 8 communicating with the liquid uniform distribution groove on the nozzle bottom part 1, and the liquid inlet 8 is connected with the nozzle replenishment pipeline 14. The liquid enters the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com