fuel tank test basket

A fuel tank and water testing technology, which is applied to coatings and devices for coating liquid on the surface, can solve the problems of inconvenient safe operation for workers, inconvenient production adjustments, and affecting the qualification rate of fuel tanks, so as to reduce the occlusion area, Fast, accurate and reliable sealing and clamping to ensure the effect of water testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

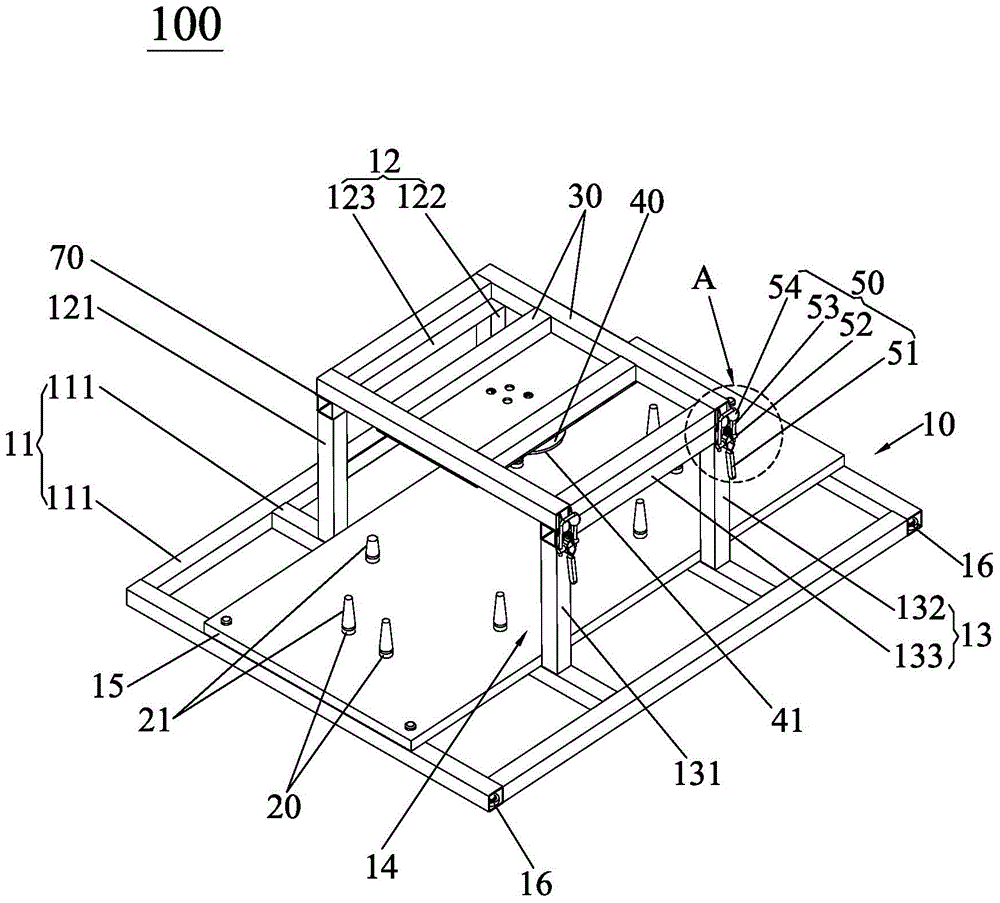

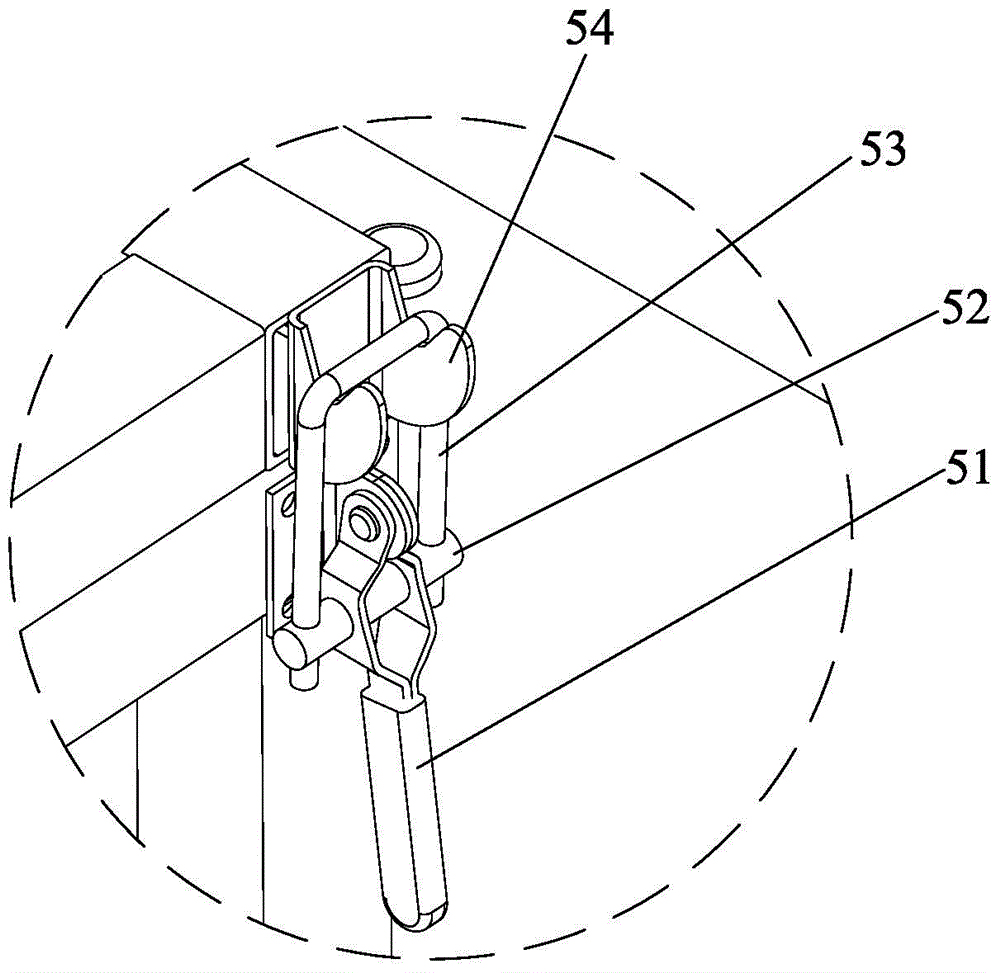

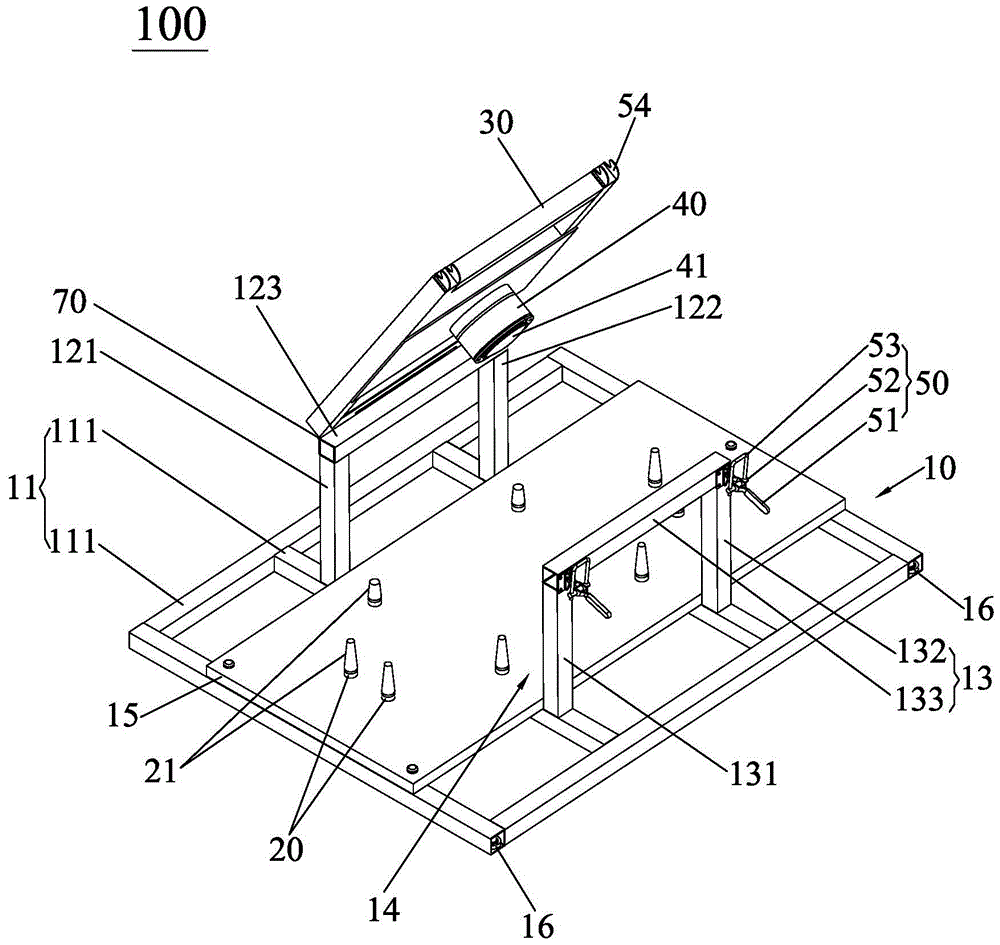

[0024] see Figure 1 to Figure 3 , the fuel tank water test basket 100 of the present invention is used to accommodate a fuel tank 200, and the top of the fuel tank 200 has a circular fuel tank mouth 210, wherein the fuel tank test water basket 100 of the present invention includes a basket frame 10, a positioning interference column 20 and Open and close the bracket 30. The basket frame 10 includes a horizontal support 11 and a first support support 12 and a second support support 13 standing on the horizontal support 11 and having the shape of a door frame. The first supporting bracket 12 and the second supporting bracket 13 are arranged longitudinally along the horizontal bracket 11, that is, as figure 1 ,as well as Figure 3 to Figure 6 As shown, the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com