Device and method for accurately placing thimbles

A thimble and precise technology, applied in the direction of assembling printed circuits with electrical components, can solve the problems of placing large boards for a long time, difficult to ensure smooth tracks, and crushing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

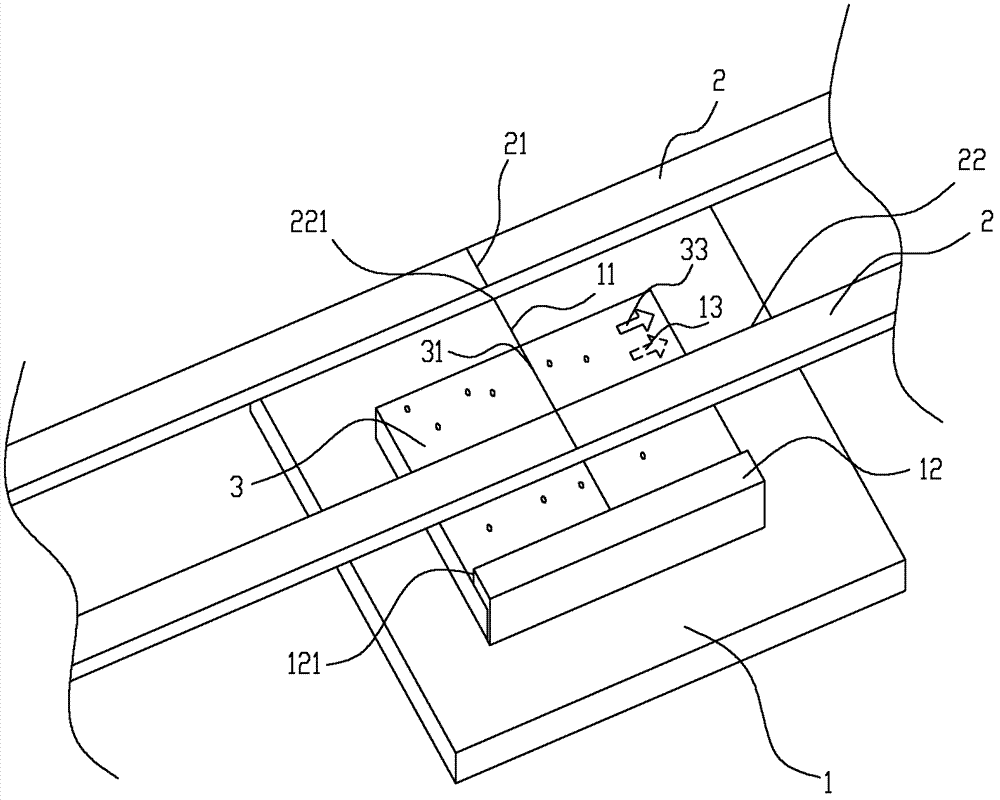

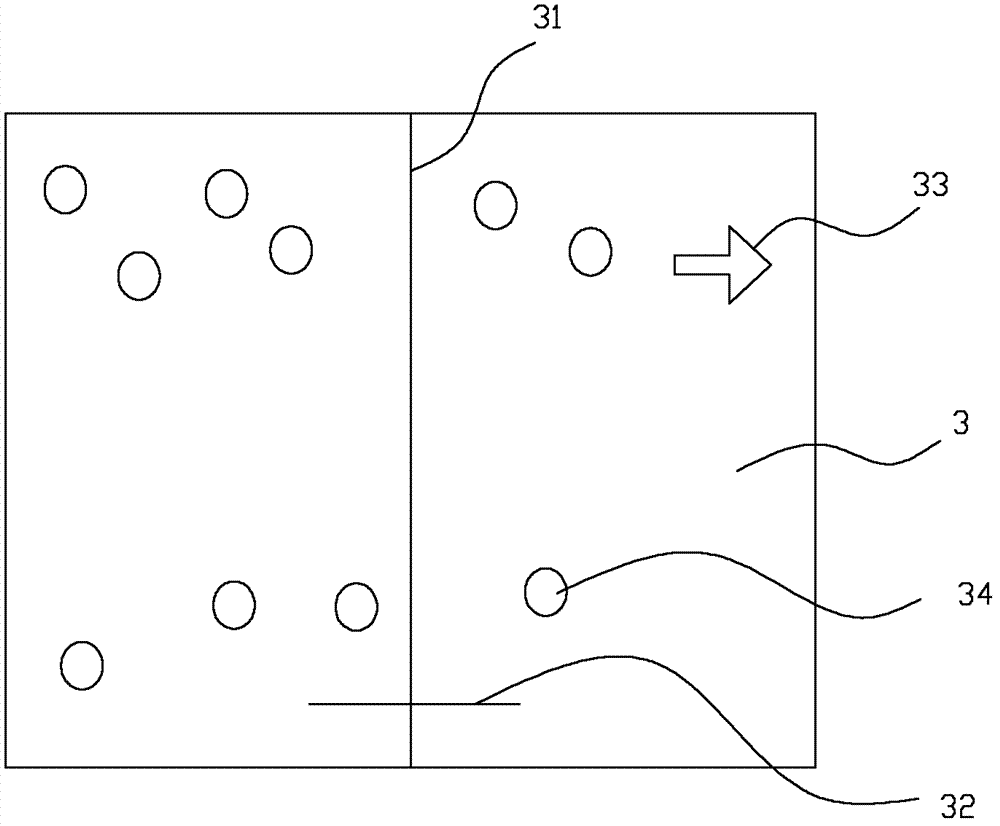

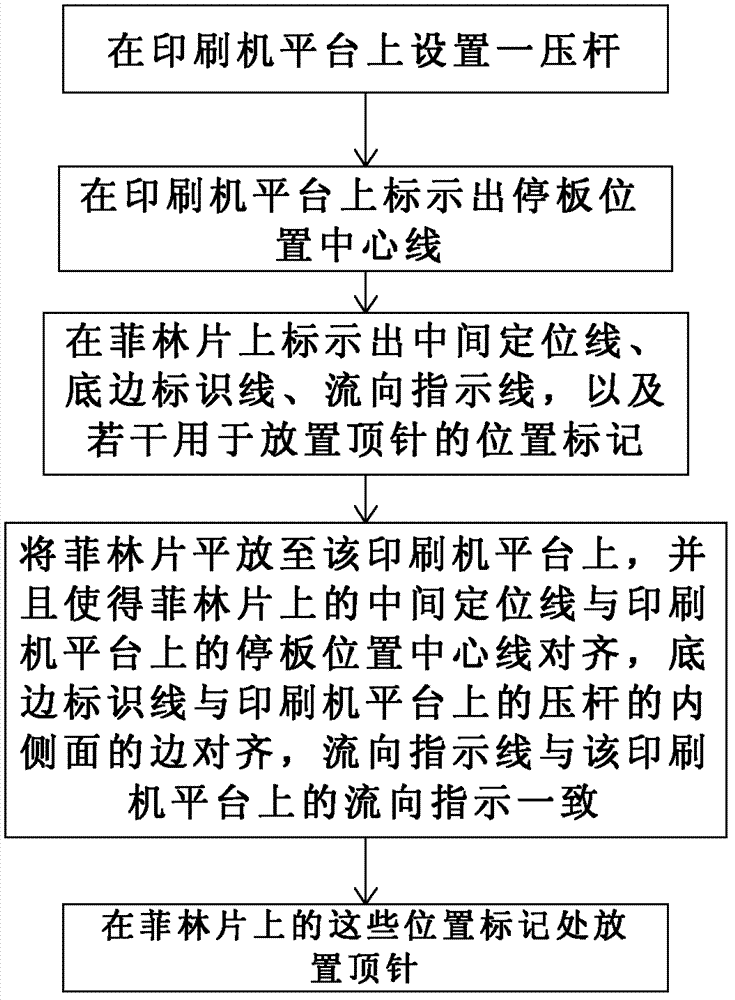

[0023] see figure 1 , there are two rails 2 for transmitting PCB boards on the top of the printing machine platform 1 and near the two sides. The bottom edge on the production surface is aligned with the edge of the inner side 22 of the track 2, so as to avoid the track from covering the surface to be printed. It is worth mentioning that the inner side 22 here refers to the opposite surface of the two tracks. There is a center point 221 corresponding to the center line 21, that is, the center point 221 is located on a line perpendicular to the center line 21 and is aligned with the end points of the center line 21. This center point 221 is a conventional mark on the track, and will not be repeated. . The PCB board is transported on the track through the belt. When the PCB board to be printed reaches the sensor (not shown in the figure) sensing area on the printing machine platform 1, the belt will suspend the transmission, and the PCB board to be printed stops at this time. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com