A concrete surface treatment process

A technology of concrete surface and treatment process, which is applied in the field of architectural concrete, which can solve problems such as shedding, uneven surface mortar, and reduced thickness of surface mortar application, and achieve the effects of reducing dripping, increasing solidification molding rate, and improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

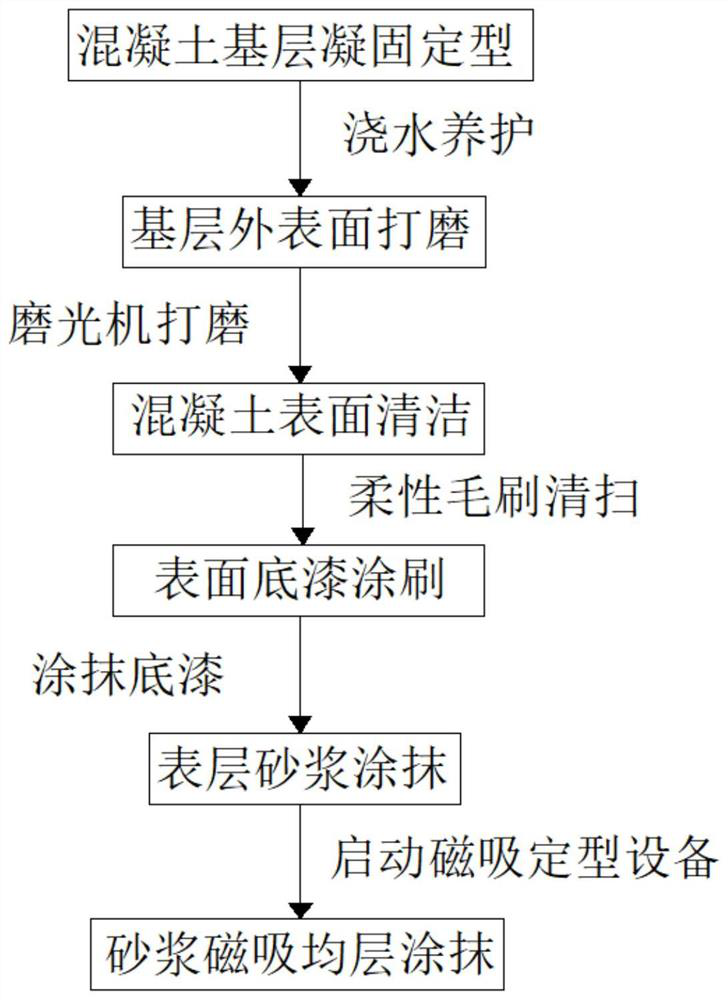

[0042] see figure 1 , a concrete surface treatment process, comprising the following steps:

[0043] Step 1. The concrete base is solidified and formed. After the concrete surface is poured and constructed, it is left to dry. After the concrete surface is solidified, the construction personnel perform watering and maintenance;

[0044] Step 2. Grinding the outer surface of the base. After cleaning the concrete base, construction workers first use a grinder and a wire brush to polish the outer surface of the concrete;

[0045] Step 3, cleaning the concrete surface, cleaning the outer surface of the solidified concrete base, using a flexible brush to clean the concrete base, and using a vacuum cleaner in time to clean up the dust and cement slag after cleaning;

[0046] Step 4: Brushing the surface primer, use flexible brushes to apply the primer on the outer surface of the concrete base after cleaning, so that the primer completely covers the outer surface of the concrete base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com