A method for preparing superhydrophobic self-luminous coating

A self-luminous coating and super-hydrophobic technology, which can be applied to coatings, devices for coating liquids on surfaces, pre-treated surfaces, etc., can solve the problems of super-hydrophobic self-luminous coating preparation and performance research that have not been reported in literature, etc. Achieve the effect of solving water decomposition or reducing luminous intensity, saving preparation cost, and strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 0.05g of a long-lasting luminescent body whose emission is blue (peak value is 456nm) to the mixture of 1g of PMMA high polymer monomer and initiator 2-hydroxyl-2-methyl-p-hydroxyethyl ether base phenylacetone (The ratio of monomer and initiator is 20:1), and add the cross-linking agent vinyltriethoxysilane (VTES) that mass content is 0.1%, keep stirring until the long afterglow luminous body and the monomer mix evenly, adopt The above mixture is dropped on a glass sheet by scraping method, and evenly coated with a coating machine, the coating speed is 99mm / s, and then irradiated with ultraviolet light in the wavelength range of 250-420nm for 1min, and the light intensity is 1mW, to obtain A 10 μm thick PMMA film doped with luminescent powder; then placed in a vacuum desiccator, dripping chlorosilane in an aqueous solution, and hydrolyzing and polycondensing chlorosilane to prepare a blue superhydrophobic luminescent coating, and water droplets on the coating The st...

Embodiment 2

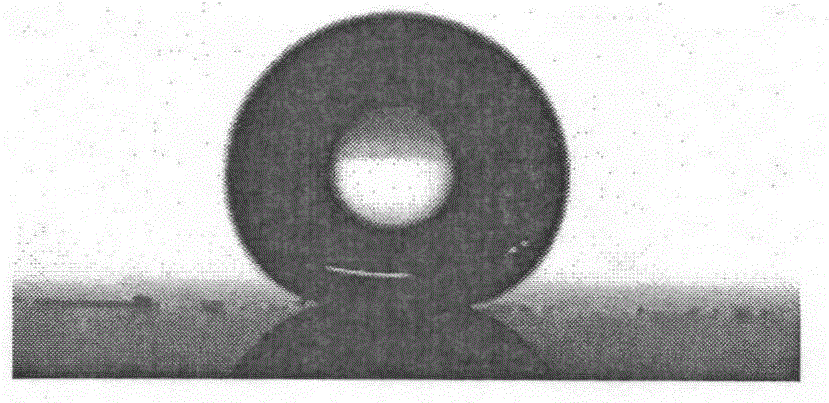

[0032] Add 2.5g of a long-lasting luminescent body whose emission is green (peak value is 510nm) into a mixture of 25g of PA high molecular polymer monomer and aqueous azo initiator azobisisobutylamidine hydrochloride (monomer and initiator The ratio of the agent is 10:1), and the cross-linking agent phenolic resin with a mass content of 1% is added, and the stirring is continued until the long-lasting luminous body is mixed evenly. Uniform coating with a coating speed of 1mm / s, and then placed at 120°C for 1h to dry to obtain a 1000μm thick PA film doped with a long-lasting luminous body; through the self-assembly of perfluorooctyltrichloromethylsilane , On this basis, a green superhydrophobic coating was prepared, and the static contact angle of water droplets on the coating was 155°-157°. as attached figure 1 As shown, the self-luminous coating prepared by the above method has a water drop contact angle of 157° as measured by the static contact angle.

Embodiment 3

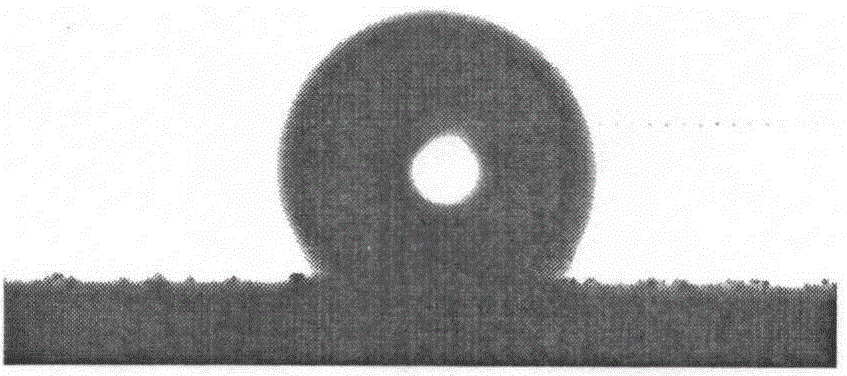

[0034] Add 3g of a long-lasting luminescent body that emits red light (peak at 780nm) into a mixture of 5g of PET monomer and initiator benzophenone (DP) (the ratio of monomer to initiator is 1:1), and add The cross-linking agent N, N'-methylenebisacrylamide with a mass content of 5%, and continuously stirred until the long-lasting luminous body is mixed evenly, and the above-mentioned mixture is dripped on the wood substrate by the spin coating method, and evenly mixed with a glue leveler. Spin coating, the spin coating speed is 1kr / min, and then irradiate with ultraviolet light in the wavelength range of 250-420nm for 5min, the light intensity is 2W, to obtain a PET film with a thickness of 100μm; then pass through the surface of octyltrimethoxysilane modification, successfully prepared a red super-hydrophobic surface, as shown in the attached figure 2 As shown, the self-luminous coating prepared by the above method has a water drop contact angle of 163° as measured by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com