Vegetable oil-based food grade novel antibacterial oil gel rich in polyunsaturated fatty acids, and preparation method thereof

A technology of unsaturated fatty acids and vegetable oils, which is applied in the field of food-grade new antibacterial oleogel and its preparation, which can solve problems such as unretrieved, single assembly characteristics of oleogel, inability to flexibly control the microstructure and functional properties of oleogel, etc. problem, to achieve good antibacterial activity and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 0.05% surfactin and 93% mass fraction of soybean oil into a 100mL glass beaker, and conduct ultrasonic treatment in a water bath at 80°C until the surfactin is completely dissolved;

[0033] (2) 7% mass fraction of monoglyceride is mixed with the solution in step (1), stirred and heated at 80°C for 15min, sheared at high speed for 1-2min, and the shear rate is 10000-15000r / min, to form a uniform oily liquid ;

[0034] (3) Take out the mixed solution in step (2), shear at high speed for 1-2min at room temperature, and the shear rate is 10000 r / min, then cool the oil solution at 20°C to form soybean oil oil gel, Store at 20°C.

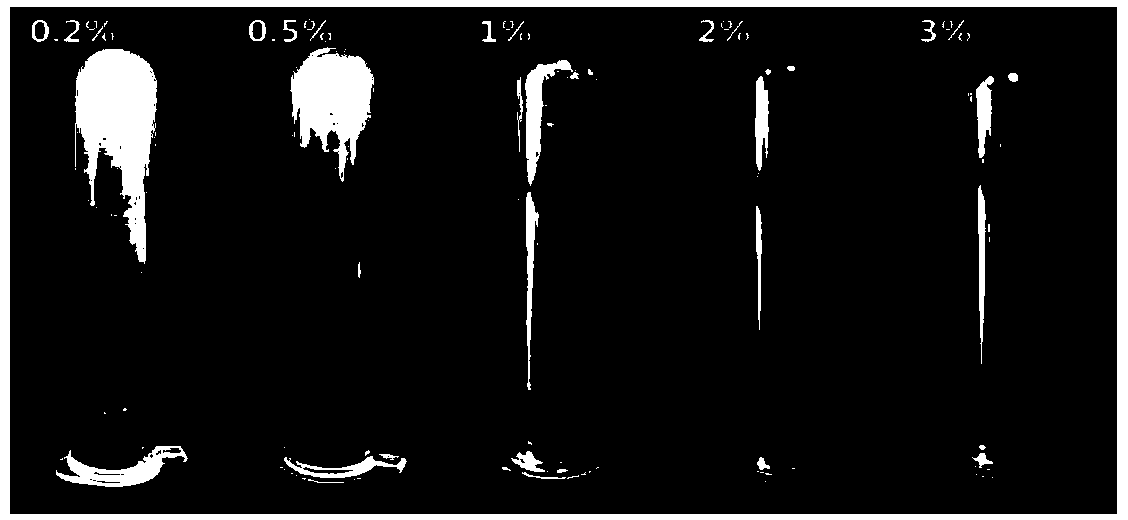

[0035] The antibacterial oil gel prepared in this embodiment is yellow in color and uniform in appearance, and the test tube inversion experiment shows that the product does not flow and is a gel substance, such as figure 1 shown.

[0036] Polarized light microscopy analysis. Take a drop of hot oil gel solution in the center of the gla...

Embodiment 2

[0039] (1) Add 0.2% surfactin and 93% mass fraction of soybean oil into a 100mL glass beaker, and conduct ultrasonic treatment in a water bath at 80°C until the surfactin is completely dissolved;

[0040] (2) 7% mass fraction of monoglyceride is mixed with the solution in step (1), stirred and heated at 80°C for 15min, sheared at high speed for 1-2min, and the shear rate is 10000-15000r / min, to form a uniform oily liquid ;

[0041](3) Take out the mixed solution in step (2), shear at high speed for 1-2min at room temperature, and the shear rate is 10000 r / min, then cool the oil solution at 20°C to form soybean oil oil gel, Store at 20°C.

[0042] The oil gel prepared in this embodiment is yellow in color and uniform in appearance, and the test tube inversion experiment shows that the product does not flow and is a gel substance, such as image 3 shown.

[0043] The operating method of the polarized light microscope analysis is the same as in Example 1. Such as Figure 4 A...

Embodiment 3

[0047] (1) Add 0.5% surfactin and 93% mass fraction of soybean oil into a 100mL glass beaker, and conduct ultrasonic treatment in a water bath at 80°C until the surfactin is completely dissolved;

[0048] (2) 7% mass fraction of monoglyceride is mixed with the solution in step (1), stirred and heated at 80°C for 15min, sheared at high speed for 1-2min, and the shear rate is 10000-15000r / min, to form a uniform oily liquid ;

[0049] (3) Take out the mixed solution in step (2), shear at high speed for 1-2min at room temperature, and the shear rate is 10000 r / min, then cool the oil solution at 20°C to form soybean oil oil gel, Store at 20°C.

[0050] The oil gel prepared in this embodiment is yellow in color and uniform in appearance, and the test tube inversion experiment shows that the product does not flow and is a gel substance, such as image 3 shown.

[0051] Antibacterial activity operating method is the same as example 2. The result is as Figure 5 As shown, the edib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com