Hydraulic upturning mechanism

A hydraulic mechanism and hydraulic technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of increasing mold processing costs, inaccurate precision, unqualified workpieces, etc., achieve good application value, ensure precision, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

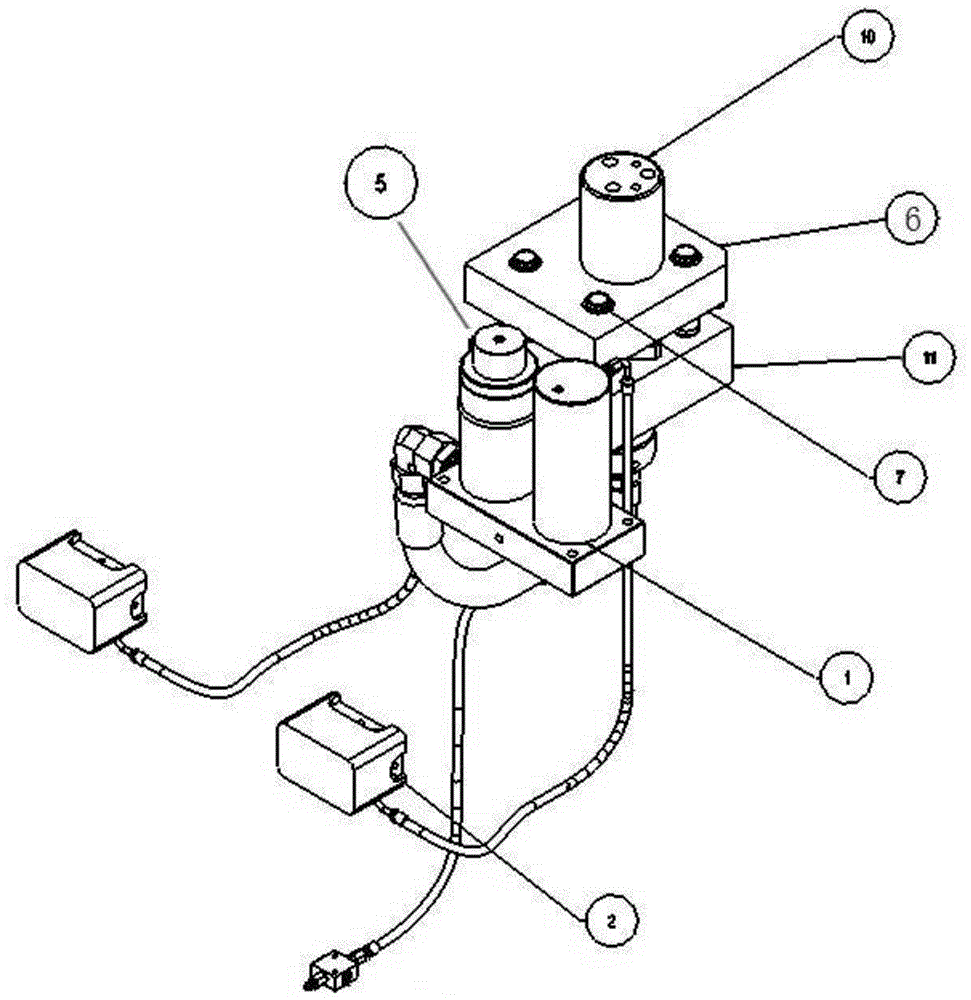

[0017] Provide a hydraulic upturning mechanism, including jacking nitrogen cylinder 4, insert mounting plate 6, guide post 7, guide sleeve 8, installation body 11, flanging insert 10, lower mold insert 13, upper pressing insert 14, of which:

[0018] The jacking nitrogen cylinder 4 is fixed on the installation body 11, the installation body 11 is fixed on the lower mold and a plurality of guide posts 7 are fixed on the upper surface;

[0019] An insert mounting plate 6 is fixed on the top of the jacking nitrogen cylinder 4, and a guide sleeve 8 is fixed on the insert mounting plate 6. The guide sleeve 8 is set on the guide post 7 and can slide up and down along the guide post; Swipe for guidance.

[0020] The flanging insert 10 is fixed on the insert mounting plate 6; the top of the flanging insert 10 has a cutting edge;

[0021] The lower mold insert 13 is fixed on the lower mold by screws, and the lower mold insert 13 has a recessed through hole matched with the flanging i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com