A chilled iron core frame assembly device and manufacturing method for casting sand core of generator cylinder body

A combined device and generator technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of increasing the risk of sand inclusion in castings, less use, and easy drop of cold iron, so as to ensure process quality stability, Reduce the risk of falling and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

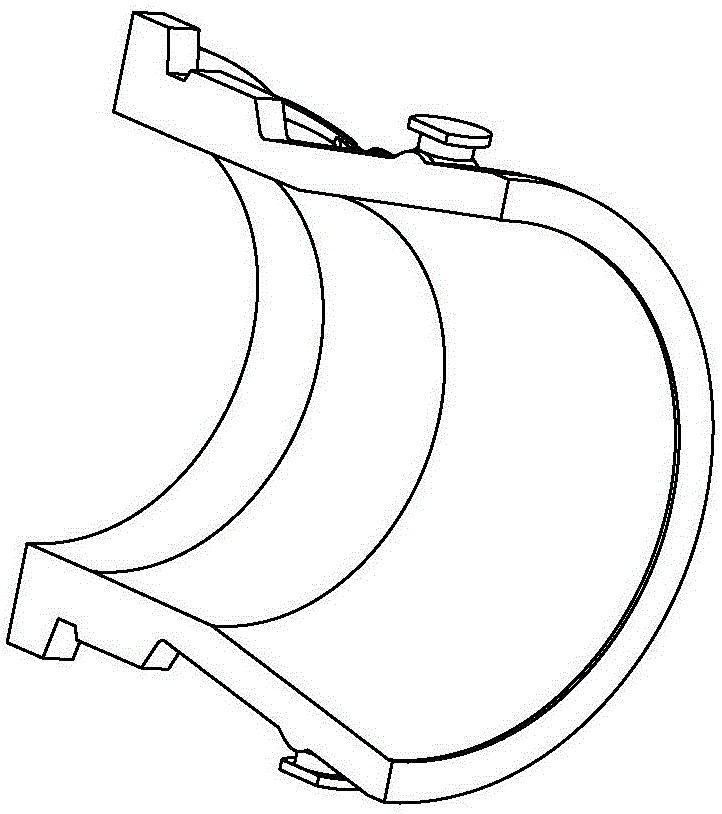

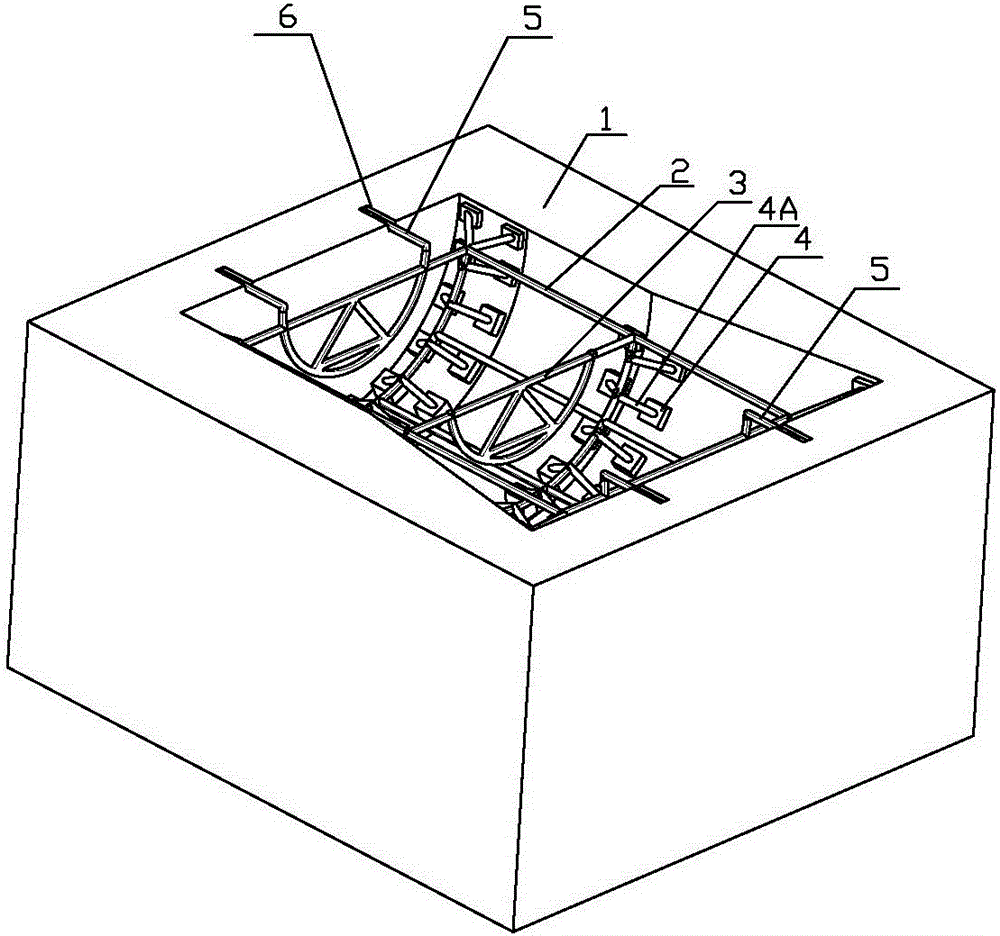

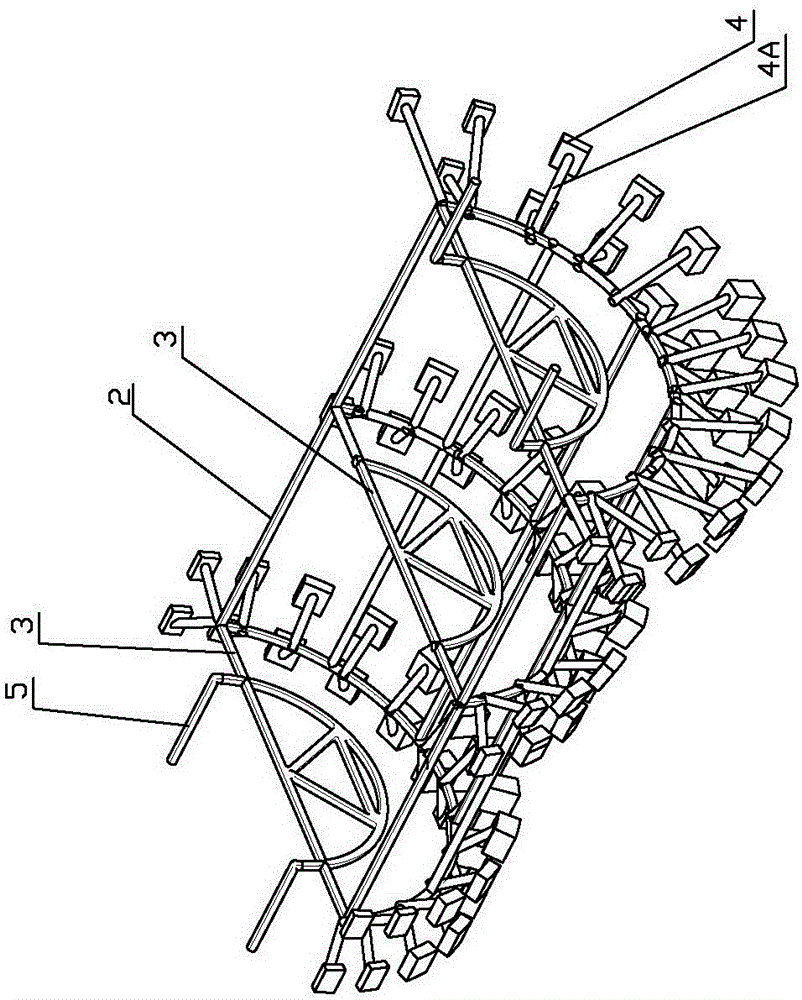

[0034] Such as figure 2 and image 3 Shown is the chilled iron core bone combination device for generator cylinder casting sand core of the present invention, including a core box 1, which is used to form a semi-cylindrical sand core, and the bottom surface of the core box 1 is provided with an arc-shaped inner surface. The core box 1 is also provided with a fixedly connected cold iron core bone combination device for core making; wherein the cold iron core bone combination device includes several bus core bone 2 parallel to the arc-shaped inner surface of the bottom surface of the core box and at equal distances, The two ends of the bus core frame 2 and the two ends are supported and connected by a number of semicircular core frame brackets 3 arranged in parallel, and the core frame brackets 3 at both ends are respectively equipped with positioning holes for positioning and installation with the core box 1. The pin 5 and the upper end surface of the core box 1 are correspon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com