Slitting machine for producing extruded polystyrene foam boards

A technology for extruded polystyrene and foam boards, which is applied in the field of slitting machines, and can solve the problems of inaccurate width of extruded polystyrene foam boards and affecting the use of boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

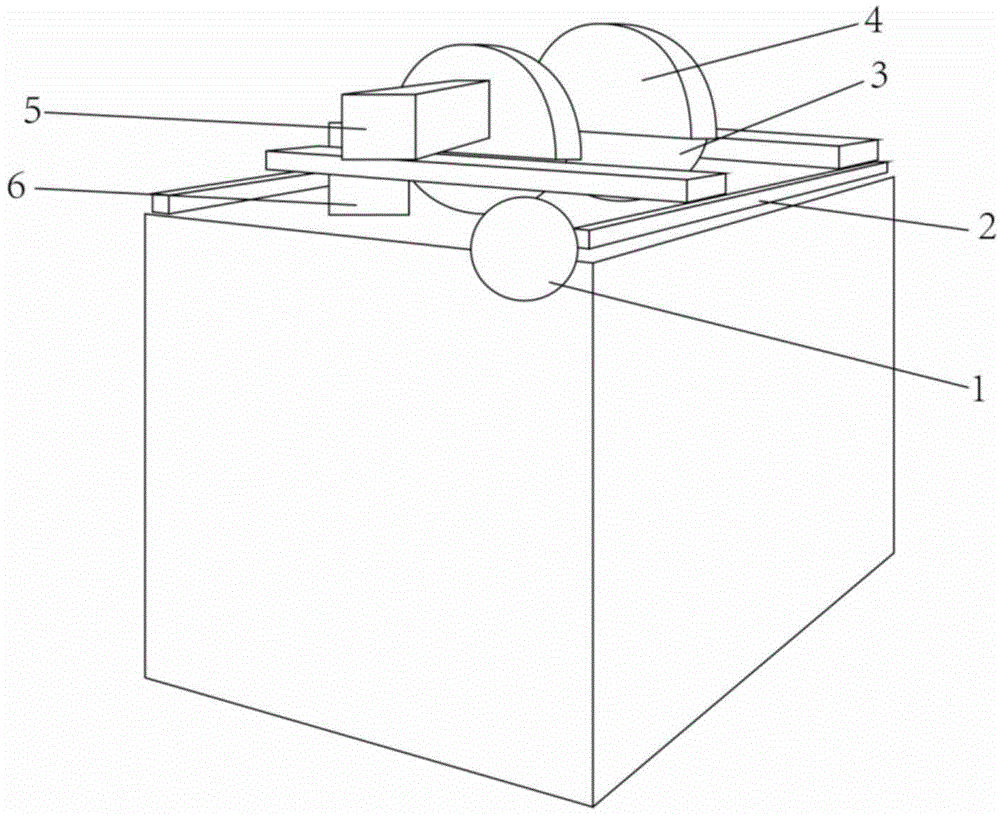

[0014] like figure 1 Shown: a slitting machine for producing extruded polystyrene foam boards, including a frame, a bracket, a sliding guide rail 2, a saw blade 3, a protective cover 4, a motor 5 and a rotating handle 1, and the sliding guide rail 2 is two root, horizontally installed on the frame, the saw blade 3 is two, respectively installed on both sides of the sliding guide rail 2 through the bracket, the saw blade 3 is provided with a protective cover 4, the saw blade 3 is connected with the motor 5, the The rotating handle 1 is connected to the support through a transmission device, and the sliding guide rail 2 is provided with scale lines of dimensions. A locking device is installed on the bracket, thereby preventing the saw blade from moving and affecting the slitting precision. The bottom of the saw blade 3 is provided with a dust s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap