Method and device for calibrating gray balance

A gray balance, the last technology, applied in printing, printing presses, electrical components, etc., can solve the problems of not guaranteeing the efficiency of adjustment, wasting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In the prior art, manual calibration of the gray balance is used during the printing process, which wastes manpower and cannot guarantee the efficiency and accuracy of the adjustment process, so the embodiment of the present invention provides a gray balance calibration method and device , to automatically and accurately calibrate the gray balance in real time.

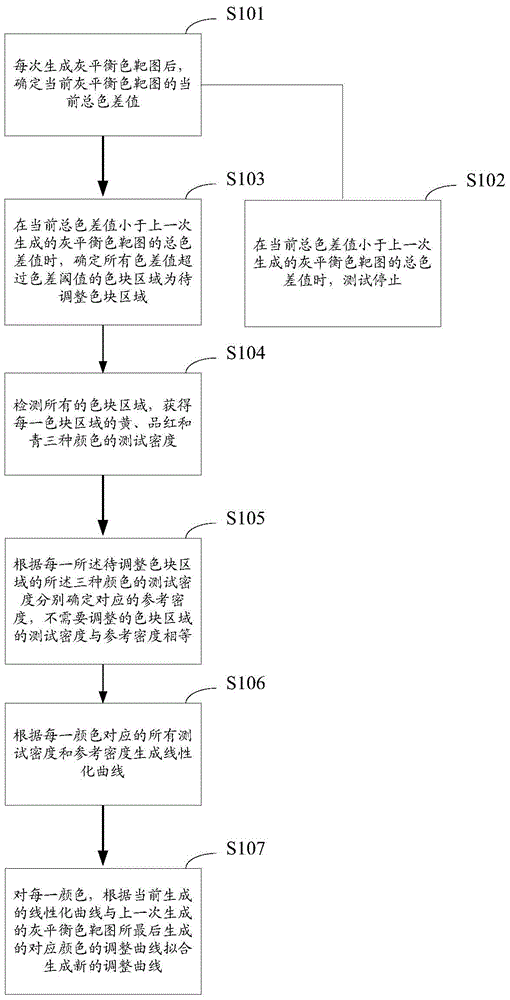

[0064] First, the embodiment of the present invention provides a gray balance calibration method, such as figure 1 As shown, the method includes:

[0065] S101, after each generation of the gray balance color target map, determine the current total color difference value of the current gray balance color target map;

[0066] S102, when the current total color difference value is greater than the total color difference value of the gray balance color target map generated last time, the calibration process stops;

[0067] S103, when the current total color difference value is smaller than the total color differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com