Braking device for railcar

A technology for a braking device and a rail car, which is applied in the directions of braking, transportation and packaging, and railway car body parts where the braking element interacts with the track, can solve problems such as restricting the speed increase of high-speed trains, and achieve reliable visual judgment and low cost. , to avoid the effect of signal error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

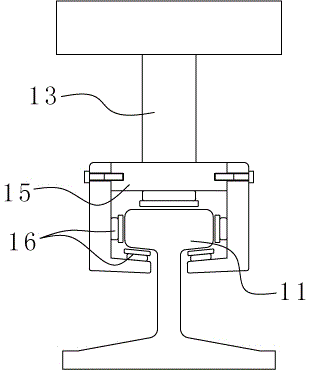

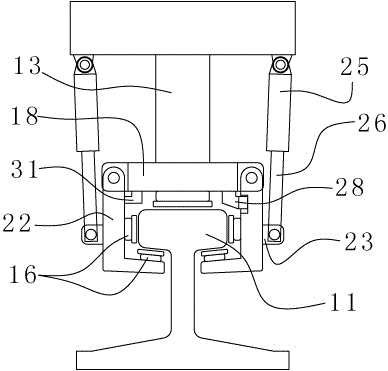

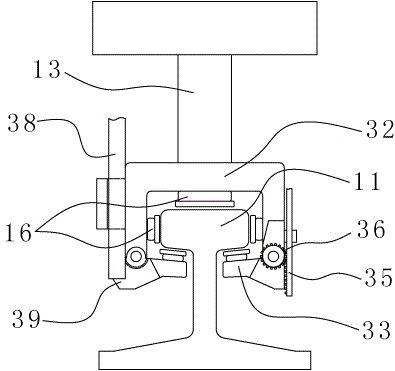

[0018] Such as figure 1 As shown, a rail car braking device shown in the first embodiment of the present invention is installed on the wheel frame of the rail car wheel set, and the rail car braking device includes a brake frame 13 installed on the wheel frame, so that the brake The device maintains a relatively stable relative position with the track rail 11. The brake frame 13 includes a rail sleeve 15 with a T-shaped groove inside and can half-embrace the steel rail 11, so that the cross-sectional shape of the brake frame 13 is an ancient Chinese character with a half opening in the middle of the bottom. The rail sleeve 15 is set on the periphery of the rail 11, and the top, left side, right side, left bottom, right bottom and the rail 11 inside the rail sleeve 15 are all provided with brakes 16 fixedly connected to the rail sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com