A method for quick hoisting of suspended vertical containers

A hanging and container technology, applied in the directions of load hanging elements, transportation and packaging, can solve the problems of cumbersome lifting cover production, inconvenient lifting of vertical containers, and large damage to wire ropes, saving labor costs and labor time. , Save the cost of procurement and production, and save the effect of crane shifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

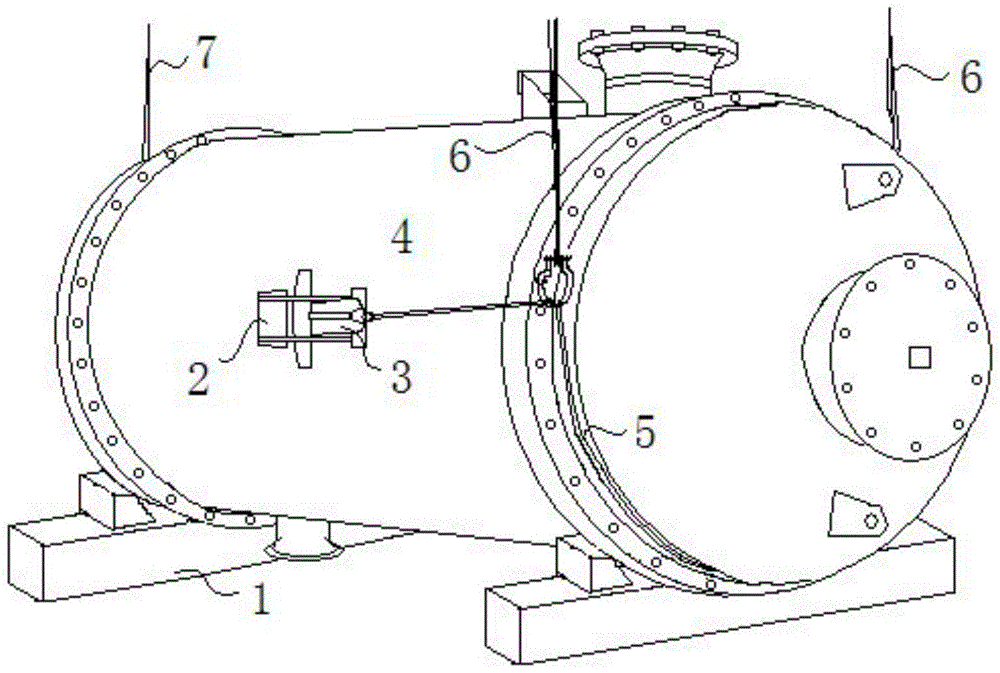

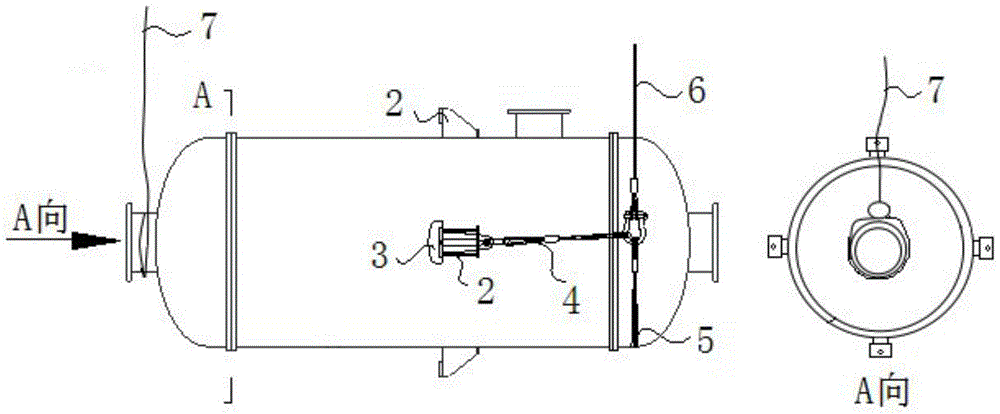

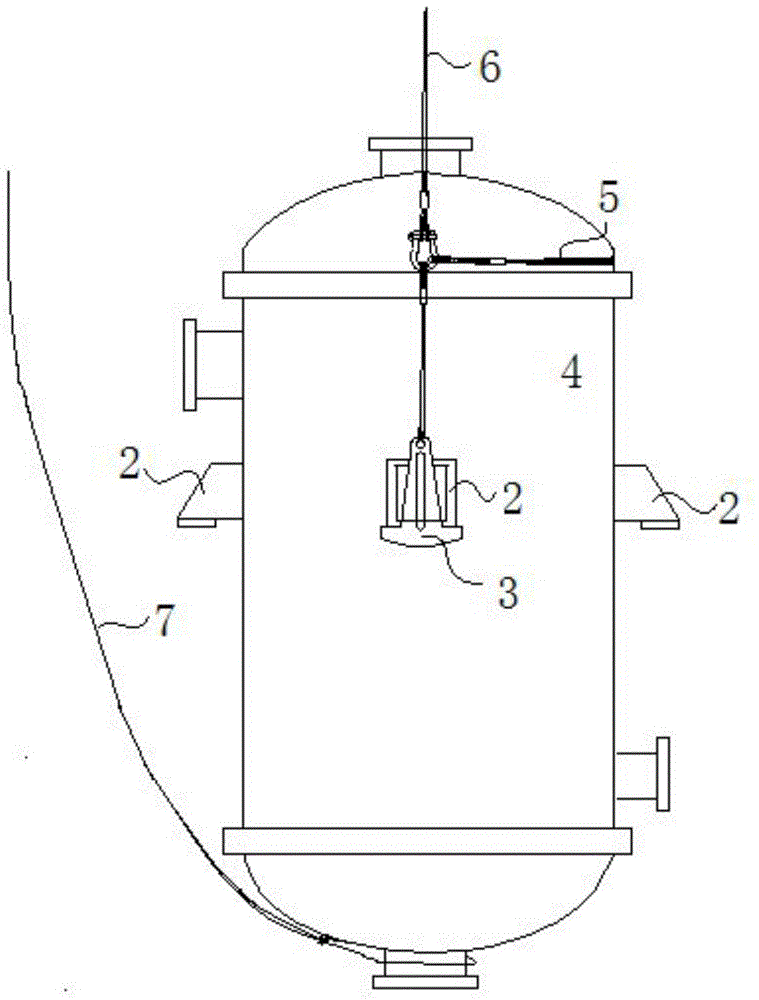

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the spreader system used in a method for quick lifting of a suspended vertical container of the present invention includes a sling, an anchor hanger 3 and a snap ring, and the anchor hanger 3 includes an anchor hanger 31 and a threading out part 32, the anchor hanging part 31 and the passing part 32 are perpendicular to each other to form a T shape, and the anchor hanging 3 is provided with a long hole in the length direction of the passing part 32, which is easy to hold, reduces the weight of the anchor hanging and makes the The anchor hanger is elegant in appearance, and the said piercing part 32 has a snap ring hole 33 at the end away from the anchor hanger part 31 for connecting with the sling. Described sling includes: connecting sling 4, is used to connect anchor hanger 3 and main sling 6; Pocket bottom sling 5, is used to bear the lifting force of vertical container; Main sling 6, conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com