an internal heater

A technology of inner heater and inner cavity, which is applied in the preparation of wort, brewing of beer, biochemical equipment and methods, etc. It can solve the problem of limiting the total evaporation of wort, excessive foaming in boiling pots, and the impact of wort quality, etc. problem, to achieve the effect of flexible debugging, elimination of bubbles, and simple adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

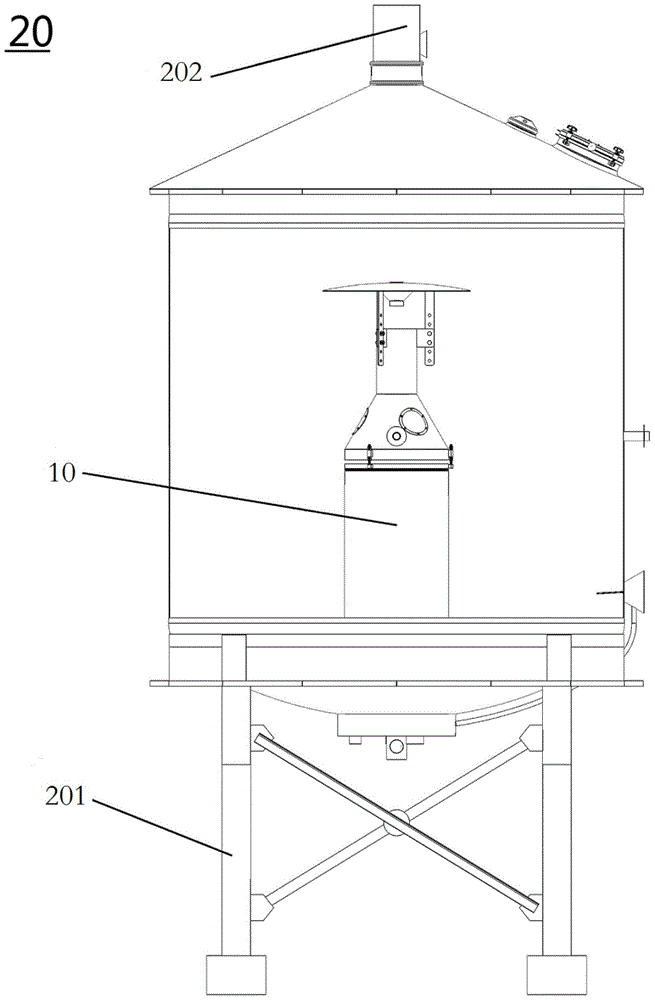

[0025] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a schematic diagram of a boiling pot 20 used in a brewery. In the figure, there are four legs 201 at the bottom of the boiling pot 20 and a chimney 202 at the top. The inner heater 10 is placed in the center of the boiling pot 20. The bottom of the inner heater 10 rests on the Root steam pipes H1 and H2 and a condensed water pipe C1 are supported, and the space between the bottom of the internal heater 10 and the bottom of the boiling pot 20 is the entrance where the wort is sucked into the internal heater 10 during heating.

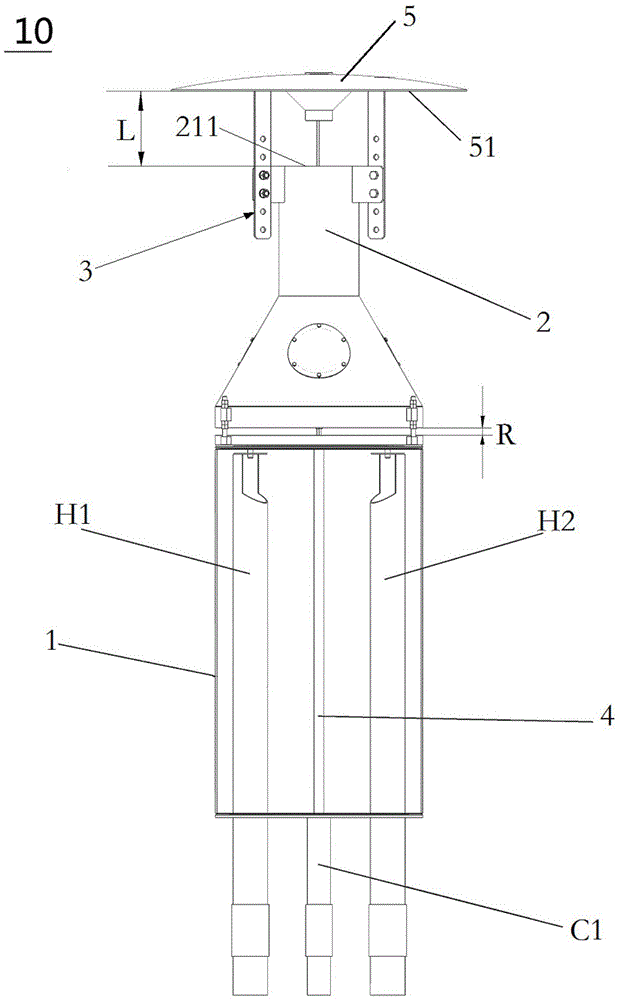

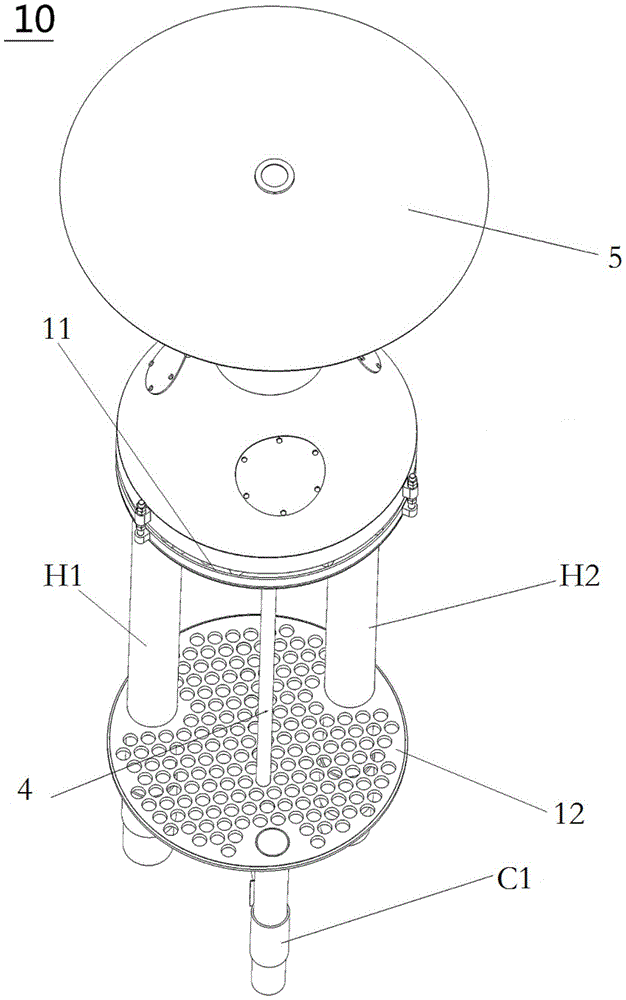

[0026] Such as figure 2 , image 3 with Figure 4 As shown, a preferred embodiment of the present invention provides an internal heater 10, comprising:

[0027] The cylinder body 1 forms a closed inner cavity together with its two end faces 11 and 12; the cylinder body 1 is provided with pipes H1 and H2 for introducing external steam int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com